Method for preparing graphene in screw extruder through crystal form inducing

A screw extruder and screw extruder technology, applied in the field of graphene preparation, can solve the problems of difficulty in obtaining graphene, small size of graphene sheets, difficulty in peeling graphene, etc., and achieve continuous and stable preparation, complete layer structure, Avoid the effect of synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

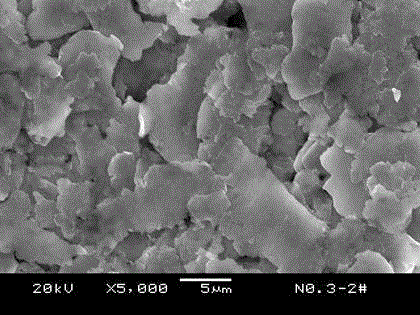

Image

Examples

Embodiment 1

[0037] (1) Melt 10kg of sucrose under heating, add 0.1kg of boric acid and 0.05kg of ammonium carbonate, and grind and disperse through a colloid mill for 25 minutes, so that boric acid and ammonium carbonate are evenly dispersed in the sucrose;

[0038] (2) Pump the grinding material obtained in step (1) into a twin-screw extruder rotating in the same direction. The length-to-diameter ratio of the screw extruder is set to 48 / 1, and the screw extruder moves from the feed end to the discharge end in turn. There are three parts: dispersion section, crystal form induction section, and shear stripping section. The dispersion section is composed of conveying thread elements, toothed thread elements, and 90° meshing thread elements. The crystal form induction section is composed of 90° meshing thread elements and compression thread elements. , the shearing and peeling section is all composed of 90° meshing thread elements; the temperature of the dispersion section is controlled at 12...

Embodiment 2

[0042] (1) Heat and melt 15kg of maltose to form a slurry, add 0.3kg of crystal form inducer boric acid and 0.15kg of ammonium bromide, and grind and disperse through a colloid mill for 10 minutes, so that the crystal form inducer is evenly dispersed in maltose, and ground material;

[0043] (2) Pump the grinding material obtained in step (1) into a co-rotating three-screw extruder, and the screw extruder is sequentially equipped with a dispersion section, a crystal form induction section, and a shear stripping section from the feed end to the discharge end Three parts, the temperature of the dispersion section is controlled at 150°C, the temperature of the crystal form induction section is set at 190°C, 220°C, and 250°C, and the temperature of the shearing and peeling section is 500°C. The screw extruder is produced under the condition of high-speed rotation of 1200rpm Shearing, directional extrusion of the grinding material into the dispersion section to disperse and activat...

Embodiment 3

[0046] (1) Heat and melt 10kg of lactose as a carbon source to form a slurry, add 0.3kg of crystal form inducers boric acid and 0.05kg of ammonium chloride, and grind and disperse through a colloid mill so that the crystal form inducers are evenly dispersed in the carbon source to obtain Abrasives;

[0047] (2) Pump the grinding material obtained in step (1) into a four-screw extruder rotating in the same direction. The screw extruder is sequentially equipped with a dispersion section, a crystal form induction section, and a shear peeling section from the feed end to the discharge end. Three parts, the dispersion section is composed of conveying thread elements, toothed thread elements, and 90° meshing thread elements, and the crystal formation induction section is composed of 90° meshing thread elements and compression thread elements. The reaction pressure is controlled at 3MPa by setting the compression thread , the shearing and stripping sections are all controlled by 90° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com