Hammer type forging device

A hammer-type and heavy-hammer technology, applied in the field of hammer-type forging devices, can solve the problems such as the size of the parts not meeting the standard, the deviation of the overall size of the parts, and the reduction of the qualified rate of products, and achieve the effect of improving the qualified rate, easy to reset, and easy to install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

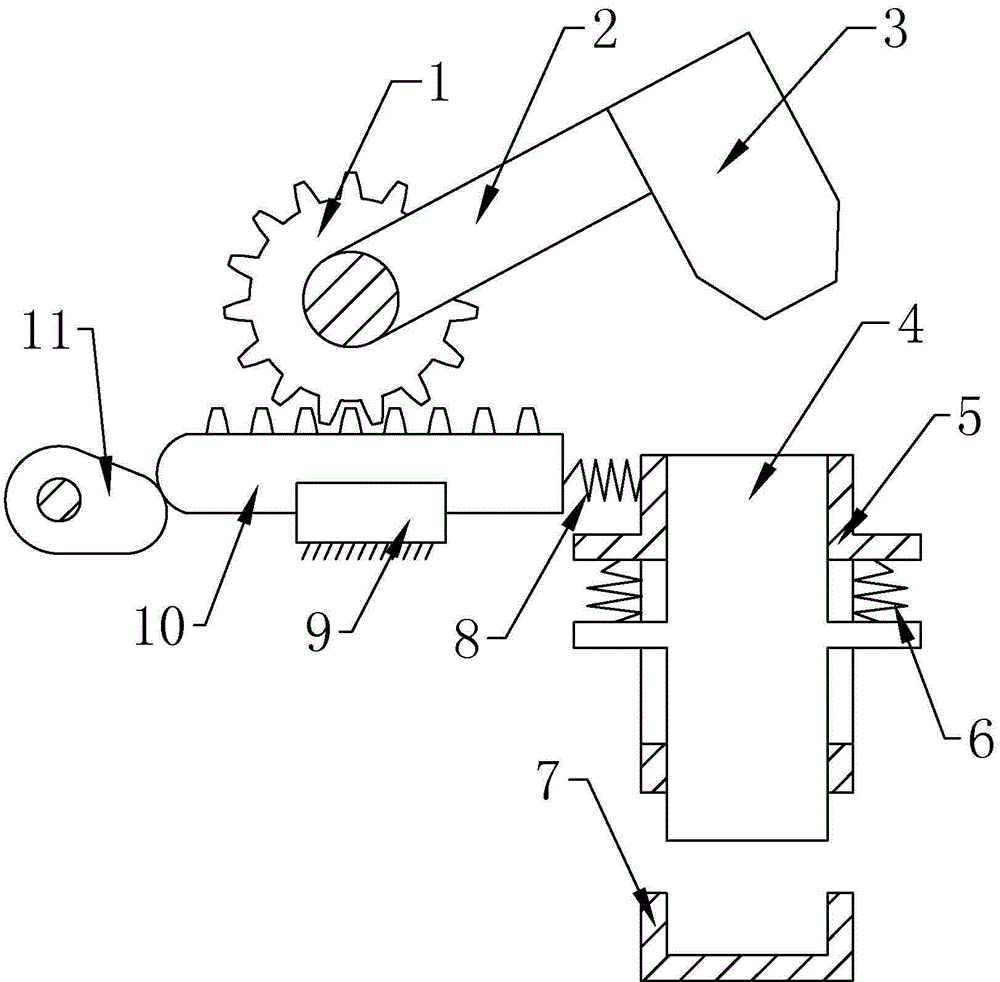

[0017] The reference signs in the drawings of the description include: gear 1, connecting rod 2, weight 3, weight 4, chute 5, first spring 6, die 7, second spring 8, fixed chute 9, rack 10, cam 11.

[0018] Example basic reference figure 1 Shown: a hammer forging device, including a main shaft, a connecting rod 2 is fixedly connected to the main shaft, and a weight 3 is fixedly connected to the end of the connecting rod 2 away from the main shaft. There is a heavy block 4, a die 7 is arranged below the heavy block 4, and the middle part of the heavy block 4 is provided with a lug passing through a bar-shaped hole of the chute, and a first spring 6 is connected between the lug and the chute 5, and the main shaft Also fixedly connected with a gear 1, the gear 1 is meshed with a rack 10, a fixed chute 9 is provided under the rack 10, a second spring 8 is arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com