Aluminum electrolysis cell waste cell lining processing method based on chemical precipitation and redox reaction

A technology for an aluminum electrolytic cell and a treatment method, which is applied in the field of aluminum electrolytic cell waste lining treatment based on chemical precipitation and redox reaction, can solve the problems of high investment and operating costs, fluoride entering the residue, and not being recycled. Achieve the effect of low processing cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

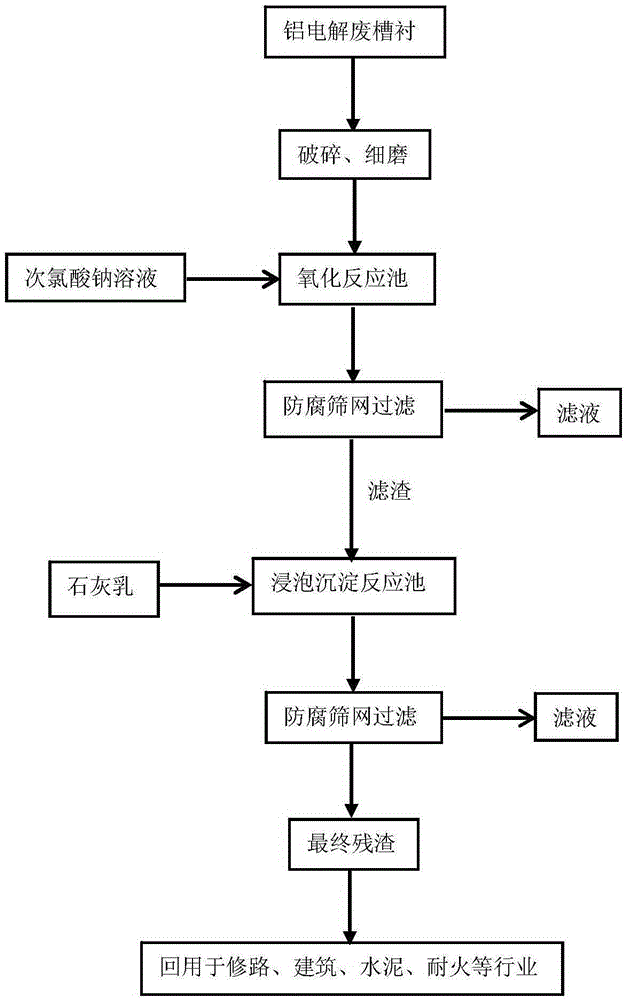

[0026] Firstly, the discarded aluminum electrolysis waste tank lining is broken into 1-3mm particles, weighed 500g and placed in the oxidation reaction tank, then put 500ml of sodium hypochlorite solution with a mass concentration of 2%, stirred and mixed for 1 hour; then passed through the anti-corrosion screen Filter the residue after the oxidation reaction, place the residue in a sedimentation reaction tank, soak it in 500ml of lime water with a mass concentration of 0.15% for 1.5 hours, and after the calcification reaction has fully occurred, filter through an anti-corrosion screen to obtain the final residue.

[0027] According to the hazardous waste identification standard and leaching toxicity standard (GB5085.3-2007), the final residue was tested for hazards. The results showed that the inorganic fluoride (excluding calcium fluoride, calculated as F-) in the leachate was 39mg / L; The chemical compound is 0.052mg / L, indicating that the final residue is no longer a hazardo...

Embodiment 2

[0029] First, break the waste aluminum electrolysis tank lining into 3-5mm particles, weigh 1500g and place it in the oxidation reaction tank, then put 1500ml of sodium hypochlorite solution with a mass concentration of 2%, stir and mix for 45min; then filter through an anti-corrosion screen Oxidize the residue after the reaction, place the residue in a sedimentation reaction tank, soak in 1500ml of lime water with a mass concentration of 0.15% for 1.2 hours, and after the calcification reaction occurs fully, filter through an anti-corrosion screen to obtain the final residue.

[0030] According to the hazardous waste identification standard and leaching toxicity standard (GB5085.3-2007), the hazard detection of the final residue shows that the inorganic fluoride (excluding calcium fluoride, calculated as F-) in the leachate is 65mg / L; The chemical compound is 0.079mg / L, indicating that the final residue is no longer a hazardous waste, thus realizing the harmlessness of the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com