Modified aluminium oxide microsphere, and preparation method and application thereof

A kind of alumina, modification technology, applied in the field of chemistry, can solve the problem of difficult to access research results and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of modified alumina microspheres, adding 1~3mLtween-80, 1~3mLspan-80 and 1~3mL n-heptanol to 15-20mL n-heptane successively under stirring and heating conditions, and then adding 100 -120mL of 2.5-4.5mol / L aluminum nitrate solution, stirred at 50-70°C for a period of time, then added 180-200mL of 1mol / L ammonia water dropwise, and continued to stir at 50-70°C for 1-3h Cool and filter to obtain colloidal precipitation, wash, dry, burn, cool, vibrate, and then filter and dry.

Embodiment 2

[0022] A preparation method of modified alumina microspheres, adding 1~3mLtween-80, 1~3mLspan-80 and 1~3mL n-heptanol to 15-20mL n-heptane successively under stirring and heating conditions, and then adding 100 -120mL of 2.5-4.5mol / L aluminum nitrate solution, stirred at 50-70°C for a period of time, then added 180-200mL of 1mol / L ammonia water dropwise, and continued to stir at 50-70°C for 1-3h Cool and filter to obtain colloidal precipitates, wash the colloidal precipitates with petroleum ether, acetone, ethanol and high-purity water, then dry and burn (burning temperature is 300-800°C, burning time is 0.5-1h, cool, shake, Then filter and dry.

[0023] The general oscillation method can be used for oscillation, such as ultrasonic oscillation. If ultrasonic oscillation is used, a small amount of high-purity water should be added before operation. The function of the vibration is to completely disperse the alumina microspheres.

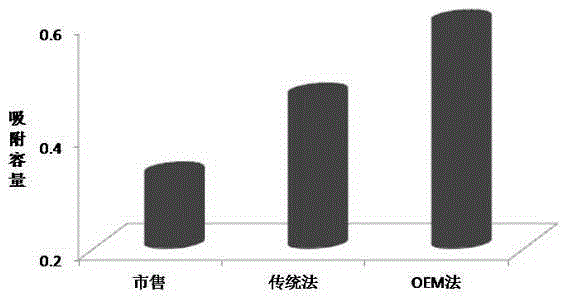

[0024] Table 1 shows the comparison of the sp...

Embodiment 3

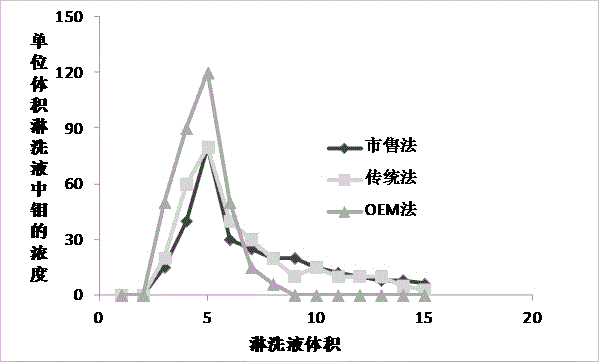

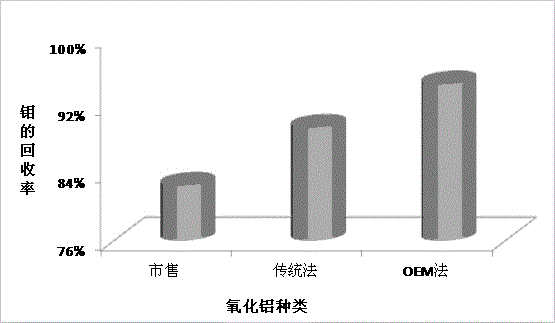

[0027] The application of a modified alumina microsphere as a chromatographic column filler to separate, measure and recover molybdenum in the spent fuel element sample solution, specifically as a chromatographic column filler using reversed-phase chromatography, reversed-phase ion pair The three-column method combining chromatography and inorganic ion exchange method is used to separate, measure and recover molybdenum in spent fuel element sample solution.

[0028] The modified alumina microspheres are all injected into the chromatographic column in advance, and the sample is injected into the quantitative tube of the chromatographic sampling valve. After manual sampling, the eluent E 1 The sample flows into the first chromatographic column under the impetus of the chromatographic column. Due to the different interactions between the chromatographic column and the components in the sample, the retention time is significantly different. The rare earth and other fissile elements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com