Scanning method for achieving high-resolution large-view-field CL imaging of plate-shaped samples

A high-resolution, scanning method technology, applied in the field of scanning to achieve high-resolution, large-field CL imaging of plate-like samples, and can solve the problems of no solution, impenetrable X-rays, thin thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

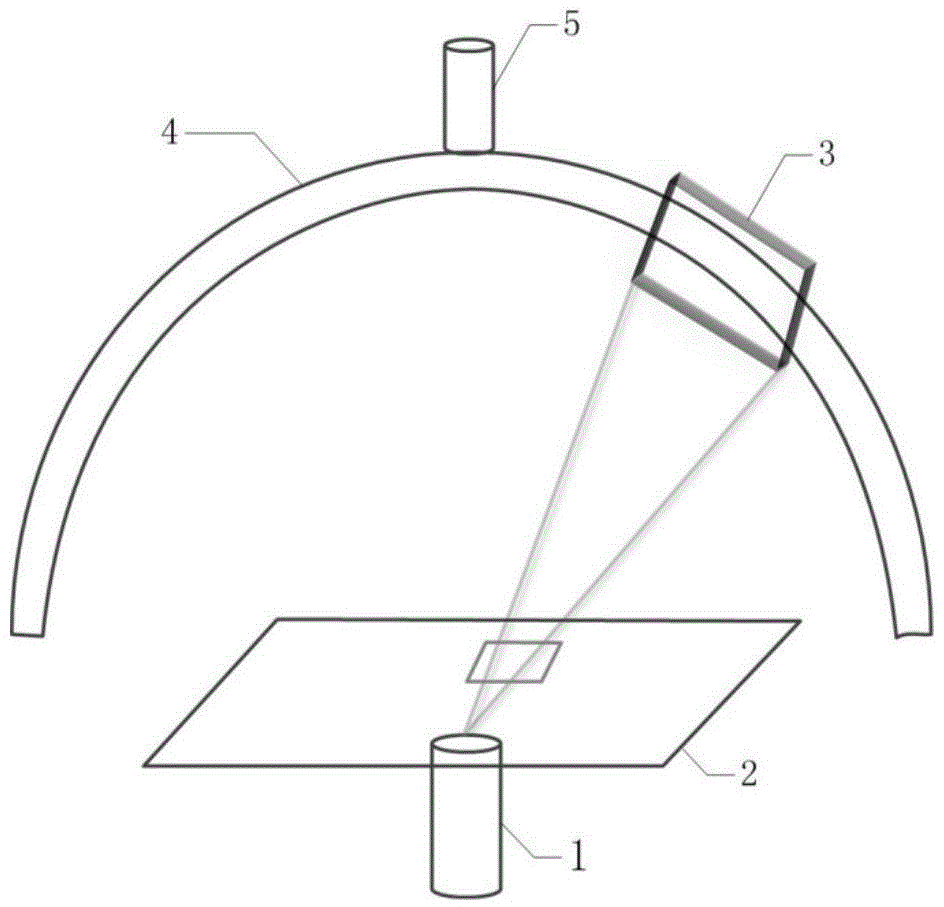

Method used

Image

Examples

specific Embodiment 1

[0058] Specific embodiment 1: A mold body for simulating the soldering of a chip on a substrate and detecting soldering bubbles.

[0059] According to the parameters in Table 2, the design Figure 15 The phantom reflected in the front view of middle a and the side view of b is a sample in which the simulated chip is soldered on the substrate and there are bubbles in the soldering layer. The cuboid 1 represents the substrate, the cuboids 2 and 3 represent the chips, the cuboids 4 and 5 represent the soldering layer, and the cylinders represent the air bubbles in the soldering layer.

[0060] Table 2

[0061]

[0062]

[0063] Under low magnification conditions, the whole sample is tomographically imaged, and the results are as follows Figure 16 As shown, the air bubbles in the visible sample are blurred. Under the condition of high magnification ratio, the sample is scanned in 2*4 blocks, "square" splicing, the result is as follows Figure 17 As shown in the figure, ...

specific Embodiment 2

[0064] Specific embodiment 2: simulate the sample of three-blade paddle, carry out " honeycomb " splicing

[0065] According to the parameters in Table 1, the design Figure 12 The "three-blade paddle" shaped phantom is shown. The phantom consists of cylinders and ellipsoids. Among them, ellipsoids 1, 2, and 3 constitute the main parts of the three-bladed paddle sample, balls 4, 5, and 6 represent defects such as air bubbles in the sample, and spheres 7 and 8 represent defects such as cracks in the sample.

[0066] Table 1

[0067]

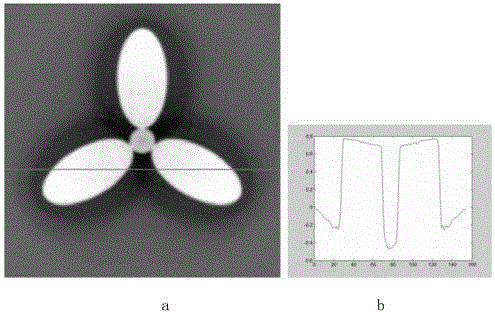

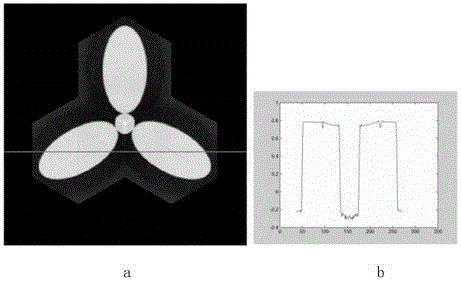

[0068] Under low magnification conditions, the entire sample is imaged to obtain a tomogram of the sample. Take the tomographic image of the middle layer ( Figure 13 a) Observation, it can be seen that under low magnification conditions, although the whole sample can be tomographically imaged, the defects in the sample cannot be clearly displayed. Take a row of data display ( Figure 13 b), the contrast of the visible defect part is smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com