Preparation method of concrete heat accumulator and concrete heat accumulation block without metal heat exchange pipeline

A technology of heat exchange pipes and concrete, which is applied in the direction of heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of high operating cost, high material cost, complex structure, etc., to reduce costs and improve heat transfer The effect of efficiency and great application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

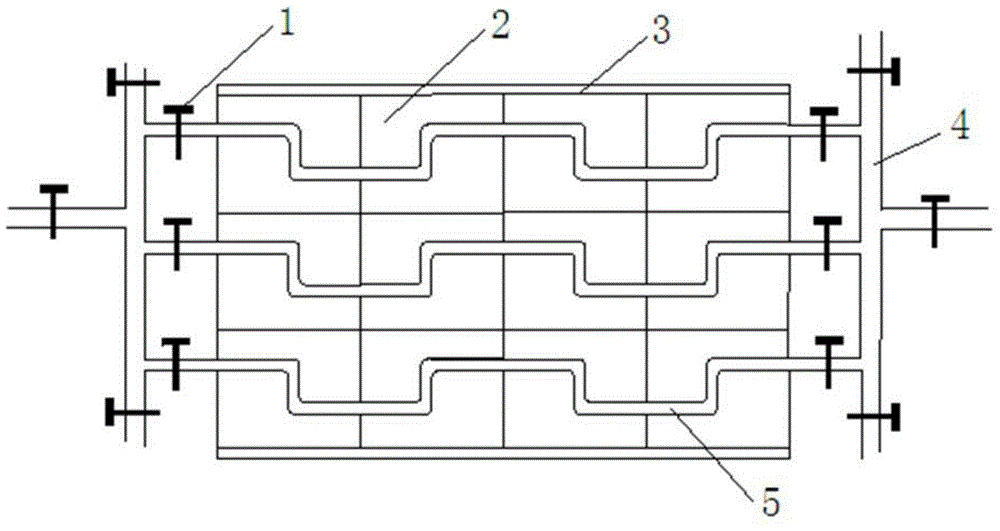

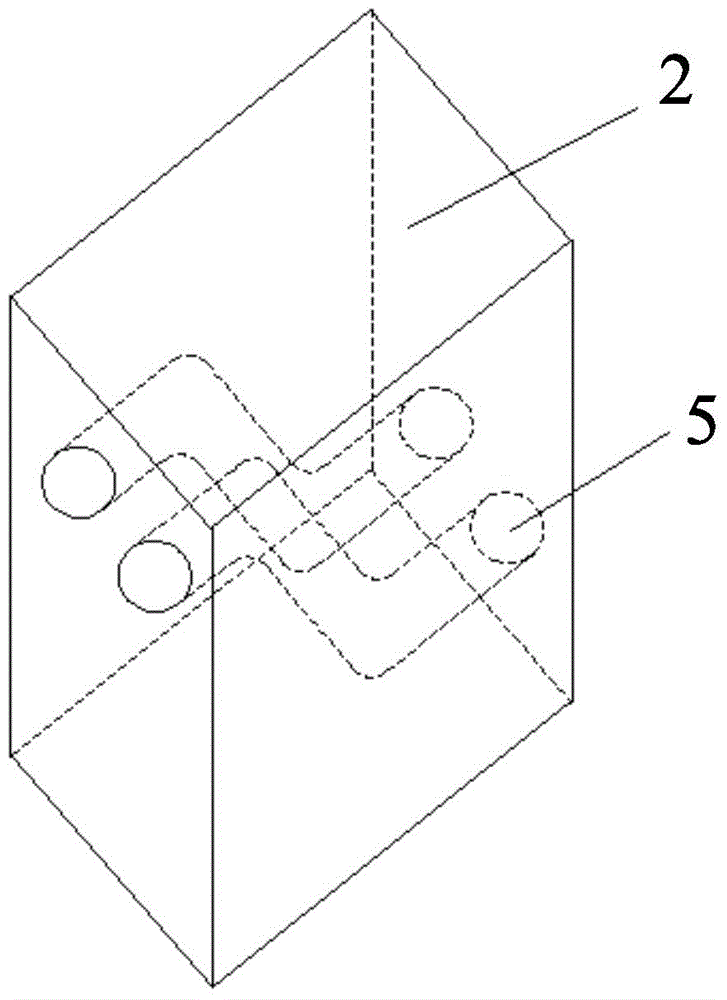

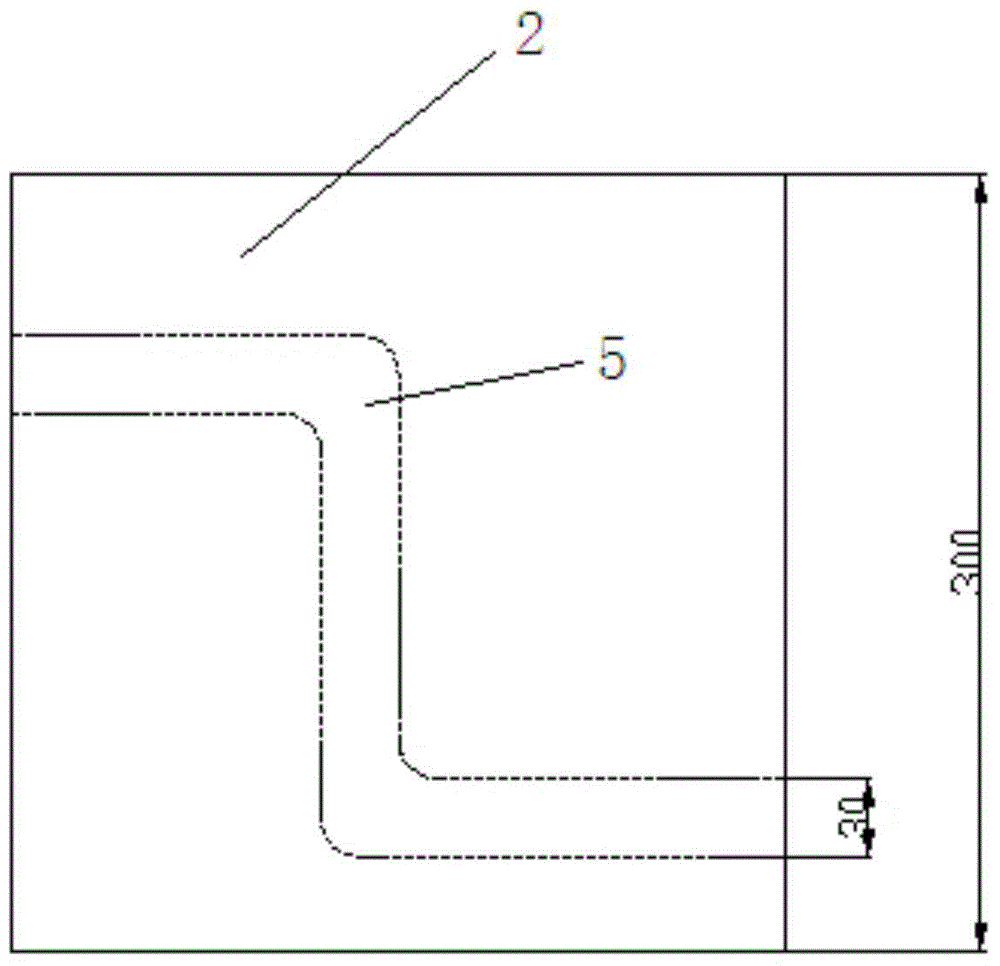

[0031] Such as Figure 1 to Figure 5 As shown, it is the concrete heat accumulator without metal heat exchange pipes provided in Embodiment 1 of the present invention, which is arranged in the vertical direction by a plurality of heat storage units, and each heat storage unit includes a plurality of concrete heat storage units arranged in the horizontal direction Heat storage blocks 2, each concrete heat storage block 2 includes a heat storage block body and an inorganic sealing coating 7, the heat storage block body is provided with a heat exchange flow channel 5, and the exchange of two adjacent heat storage block bodies The hot runners 5 communicate with each other. The inorganic sealing coating 7 is arranged on the outer wall of the heat exchange channel 5 . The concrete heat accumulator also includes a valve 1 , an external thermal insulation layer 3 and an external heat medium circulation pipe 4 . The external thermal insulation layer 3 is arranged on the periphery of ...

Embodiment 2

[0040] The structure of the concrete heat accumulator without metal heat exchange pipes in this embodiment is roughly the same as that in Embodiment 1, except that the weight ratio of the material composition of the heat storage block body and the inorganic sealing coating is different, specifically:

[0041] The weight ratio and particle size of the material composition of the heat storage block body are: 40% coke gemstone, particle size 5-20mm; steel slag 20%, particle size 5-10mm; bauxite clinker 20%, particle size 1-5mm; 300 mesh alumina Salt cement 5%; 500 mesh silica powder 7%; 300 mesh activated alumina powder 3%, 300 mesh silicon carbide powder 5%; plus 0.7% composite water reducing agent.

[0042] The weight ratio and particle size of the material composition of the inorganic sealing coating are: 200 mesh active magnesium oxide powder mass fraction is 5%, 200 mesh barium oxide powder mass fraction is 45%, 200 mesh boric anhydride is 8%, 200 mesh aluminum oxide Powder ...

Embodiment 3

[0045] The structure of the concrete heat accumulator without metal heat exchange pipes in this embodiment is roughly the same as that in Embodiment 1, except that the weight ratio of the material composition of the heat storage block body and the inorganic sealing coating is different, specifically:

[0046] The weight ratio and particle size of the material composition of the heat storage block body are: 20% forsterite, particle size 5-20mm; copper slag 30%, particle size 5-10mm; bauxite clinker aggregate 34%, particle size 1-5mm ; 300 mesh aluminate cement 5%; 500 mesh silica powder 3%; 300 mesh activated alumina powder 3%, 300 mesh silicon carbide powder 5%; plus 0.5% composite water reducing agent.

[0047] The weight ratio and particle size of the material composition of the inorganic sealing coating are: 200 mesh active magnesium oxide powder mass fraction is 5%, 200 mesh barium oxide powder mass fraction is 50%, 200 mesh boric anhydride is 5%, 200 mesh aluminum oxide P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com