A plastic-coated tape-reinforced hollow-wall winding pipe and its manufacturing method

A manufacturing method and a technology of winding pipes, which are applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems that the rigidity of hollow square pipe rings cannot be enhanced, the difficulty of production and processing technology is increased, and it is difficult to ensure the reinforcement effect, etc., and the structure is simple , The production process is easy, and the effect of enhancing the ring stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

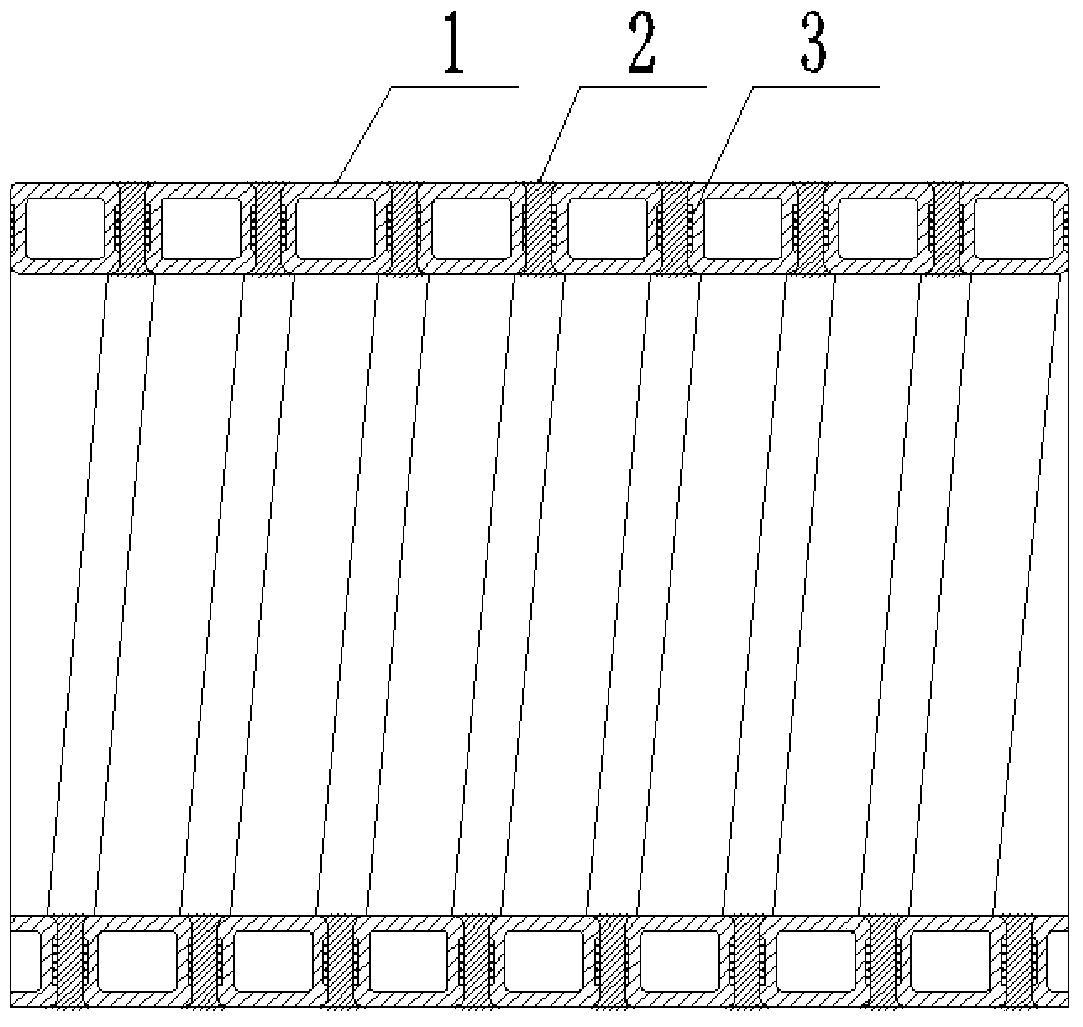

[0034] Such as figure 1 As shown, a plastic-coated tape reinforced hollow-wall winding pipe includes a square tube 1, melt glue 2, and plastic-coated tape 3; the plastic-coated tape 3 is longitudinally arranged on the side of the square tube 1 to form a plastic-coated tape-reinforced square tube. The plastic-coated tape reinforced square tube has a plastic-coated tape 3 on one side or both sides have a plastic-coated tape 3; the plastic-coated tape reinforced square tube can have one plastic-coated tape 3 or more than one plastic-coated tape 3 on one side ; During production, after the first extruder extrudes the square tube 1, heat the plastic-coated tape 3, close the heated plastic-coated tape 3 and the side of the square tube 1, and then set the plastic-coated tape reinforced square tube on On the roller mold, at the same time, the second extruder extrudes the melted glue 2, the plastic-coated tape reinforced square tube is wound to form a pipe, and the melted glue 2 is bonde...

Embodiment 2

[0040] In order to obtain the above-mentioned plastic-coated tape-reinforced hollow-wall winding pipe, a manufacturing method of the plastic-coated tape-reinforced hollow-wall winding pipe is designed. The manufacturing steps are as follows:

[0041] 1) Pre-mix the plastic raw materials and heat and melt the shape blank by the square tube extruder. At the same time, put the preheated plastic-coated reinforcement tape close to the surface of the molten material blank, and then the shape material blank and the plastic-coated reinforcement tape together Enter the cooling setting device to form a reinforced square tube with plastic coating;

[0042] 2) Set the cooled and shaped plastic coated tape reinforced square tube on the drum mold of the winding machine, wind it and extrude the melted melt adhesive gap by the melt glue extruder, roll it through the pressure roller and cool, and cut to length Become a pipe;

[0043] Such as Figure 5 As shown, after pre-mixed plastic raw materials ...

Embodiment 3

[0049] In order to obtain the above-mentioned plastic-coated tape-reinforced hollow-wall winding pipe, another method for manufacturing the plastic-coated tape-reinforced hollow-wall winding pipe is designed. The manufacturing steps are as follows:

[0050] 1) Pre-mixed plastic raw materials are heated and melted by the square tube extruder to extrude the shape material blank, and the square tube is formed by the cooling and shaping device;

[0051] 2) Place the heated plastic-coated reinforced tape close to the surface of the square tube, and roll it through a roller to form a plastic-coated reinforced square tube;

[0052] 3) Set the compounded plastic-coated tape reinforced square tube on the drum mold of the winding machine, wind it and extrude the melted melt adhesive gap by the melt glue extruder, roll it through the pressure roller and cool it, and cut it into a fixed length Pipe

[0053] Such as Image 6 As shown, after pre-mixed plastic raw materials are heated to form a melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com