A connection method and structure of a variable cross-section continuous rigid frame aqueduct

A connection method and variable section technology, applied in water conservancy projects, artificial waterways, buildings, etc., can solve problems such as stress concentration, cracking of construction joints, affecting the durability of aqueducts, etc., to reduce stress concentration, reduce connection stress, and strong waterproof ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

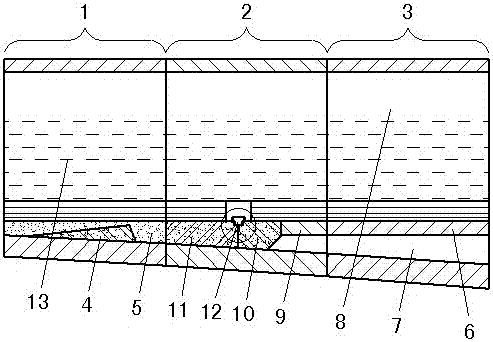

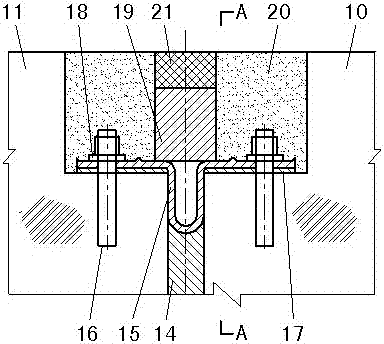

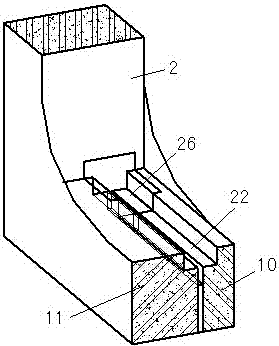

[0033] Implementation steps of the present invention are as follows:

[0034] First complete the construction of the entire single-hole aqueduct and double-hole aqueduct bottom plate of the aqueduct. When the single-hole aqueduct and double-hole aqueduct bottom plate are about to close together, complete the transition groove bottom plate at the closing dragon mouth and let it stand for 30 days. Then complete the construction of the middle plate, seal and cushion on the bottom plate of the transition tank, and reserve space for the water-stop structure of the transition tank section; use modified epoxy resin adhesive to closely paste the stainless steel water-stop end on the water-stop belt reserved Notch and web junction area; during construction, such as image 3 As shown, the stainless steel water stop is bonded to the junction area between the notch and the web of the transition groove first, and then the U-shaped GB composite rubber water stop is installed. In order to cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com