A kind of Bacillus xylosinolysine and its method for preparing α-keto acid

A technology of Bacillus glycolysine and Bacillus lysine, which is applied in the field of Bacillus xylosyllysine to prepare α-keto acid, which can solve the problem that the production intensity of α-keto acid is not high and it is difficult to realize industrialization problems such as broad substrate and product tolerance, broad substrate specificity, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: strain screening

[0028] (1) 20 soil samples collected from different areas were naturally air-dried and crushed, and 5 g of crushed soil samples were added to conical flasks containing 50 ml of sterile water, shaken (200 rpm) at 30 ° C for 20 min, and statically Take 1ml of the supernatant for gradient dilution, and then spread 50μl of the diluted solution on a petri dish loaded with solid medium, and incubate at 30°C for 3 days. The solid medium used for enrichment is: peptone 10g / L, beef extract 3g / L, sodium chloride 5g / L, agar 15g / L, pH7.2.

[0029] (2) Single colonies grown on the solid medium in step (1) were picked respectively, inoculated into 5 ml sterile liquid medium, and cultured on a shaker (200 rpm) at 30° C. for 24 hours. Take 1ml of the bacterial liquid, and use the 2,4-dinitrophenylhydrazine method to detect pyruvate. The positive strain was inoculated onto the solid medium in step (1), cultured at 30°C for 24h, then inoculated into 5ml...

Embodiment 2

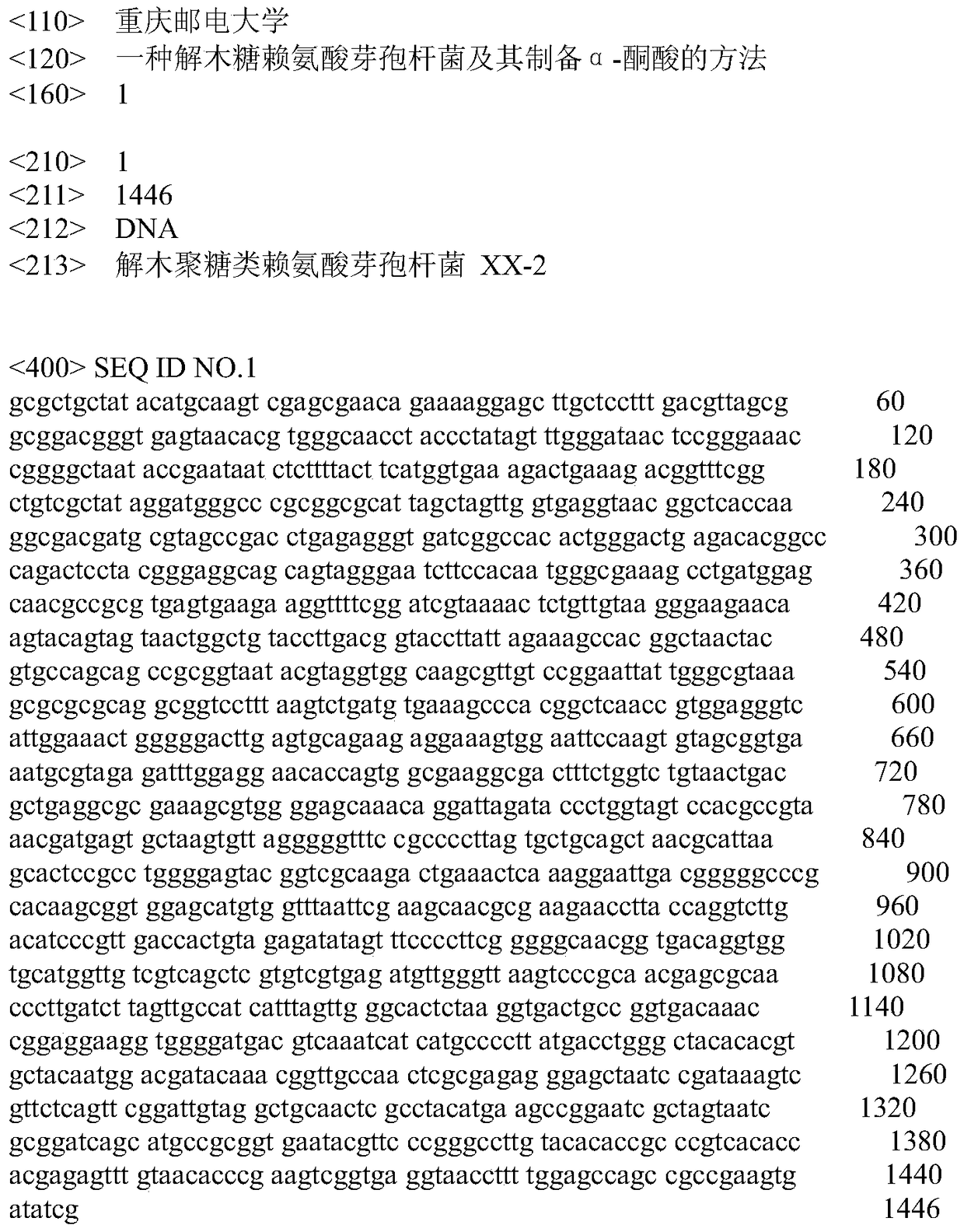

[0030] Embodiment 2: bacterial strain identification

[0031] The strain with the highest L-alanine oxidative deamination activity was identified by 16s rDNA. The strain has 100% homology with Lysinibacillus xylanilyticus, and it was named Lysinibacillus xylanilyticus XX-2. See the appendix for the 16s rDNA sequence.

Embodiment 3

[0032] Embodiment 3: Bacterial strain culture and thalline harvest

[0033] The slant medium is: 3g / L beef extract, 5g / L yeast extract, 5g / L sodium chloride, 15g / L agar, pH6.0.

[0034] The seed medium is: 3g / L beef extract, 5g / L yeast extract, 5g / L sodium chloride, pH6.0.

[0035] Enzyme production medium: 3g / L beef extract, 5g / L yeast extract, 5g / L sodium chloride, 3g / L L-alanine, pH6.0.

[0036] Slant culture: Inoculate the screened Bacillus xylosinus XX-2 on the slant medium, and culture at a constant temperature of 30°C for 48 hours;

[0037] Seed culture: inoculate the strains cultivated on the slant with an inoculation loop in 5ml of fermentation medium under aseptic conditions, and culture on a shaker (180rpm) at 30°C for 48 hours to obtain a seed solution;

[0038] Shake flask culture: the seed solution was introduced into fresh fermentation medium with 10% inoculum, and cultured on a shaker (180 rpm) at 30° C. for 48 hours.

[0039] Bacterial cell harvesting: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com