Device and method for producing super-amphiphobic paint with modification of modified particles

A modified particle and super-amphiphobic technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as low production efficiency, coating oxidation, and difficulty in continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

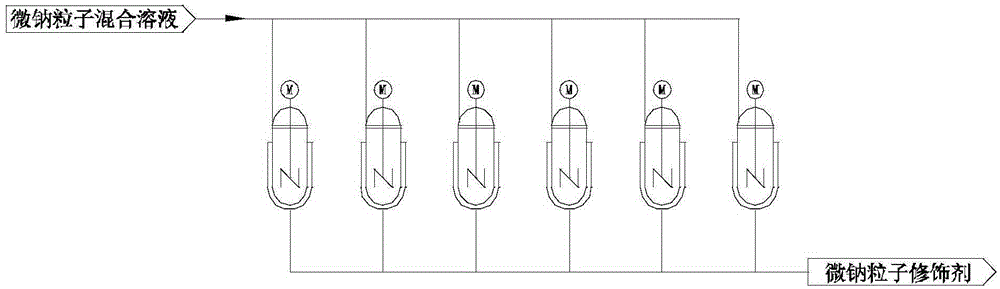

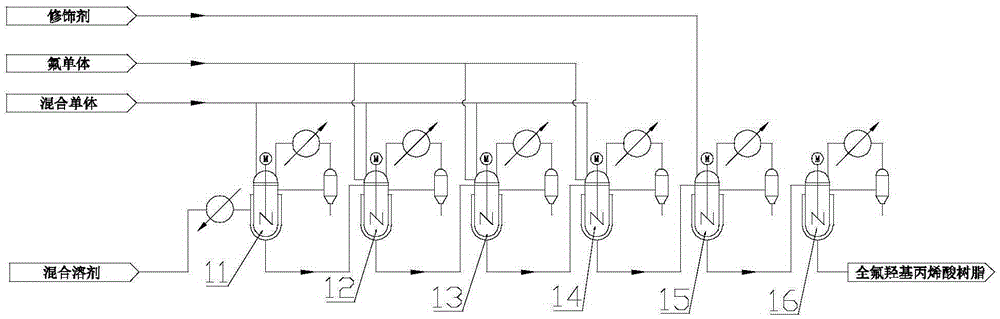

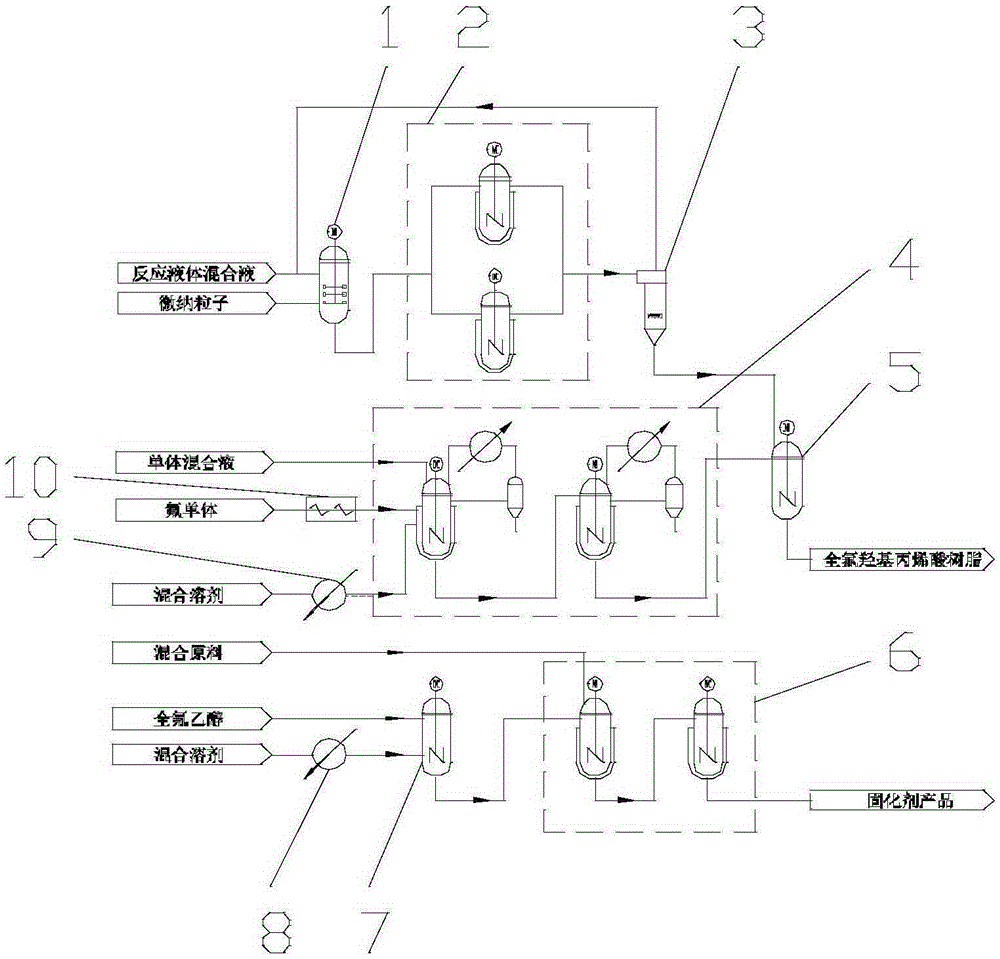

[0053] refer to Figure 1~Figure 3 , the present invention comprises a micro-nano particle modified high-speed disperser 1, a six-pot parallel reaction device 2 for micro-nano particle surface modification, a hydrocyclone 3, a six-pot series reaction device 4 for fluorine-containing hydroxyl acrylic resin, and resin component A stirring Device 5, fluorine-containing PU prepolymer curing agent double-tank series reaction device 6, fluorine-containing PU prepolymer raw material agitator 7, prepolymer raw material mixed solvent preheater 8, resin solvent preheater 9 resin monomer raw material Premixer 10.

[0054] In order to ensure that the micro-nano particles and the surface modifier can fully contact, the stirring speed of the micro-nano particle modified high-speed disperser 1 can reach up to 3000r / min. In order to achieve continuous production, speed up production, and expand production scale, the surface modification process of micro-nano particles adopts the mode of six ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com