A kind of acetaminophen tablet and preparation method thereof for preventing sticking and splitting

A paracetamol tablet and the technology of paracetamol are applied in the field of paracetamol tablet and preparation thereof, and can solve the problems of little effect of sticking and splintering, difficulty in swallowing by patients, high cost of taking medicine for patients, and the like. Improve dissolution and release, smooth and beautiful one-sided, and solve the effect of missing edges of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

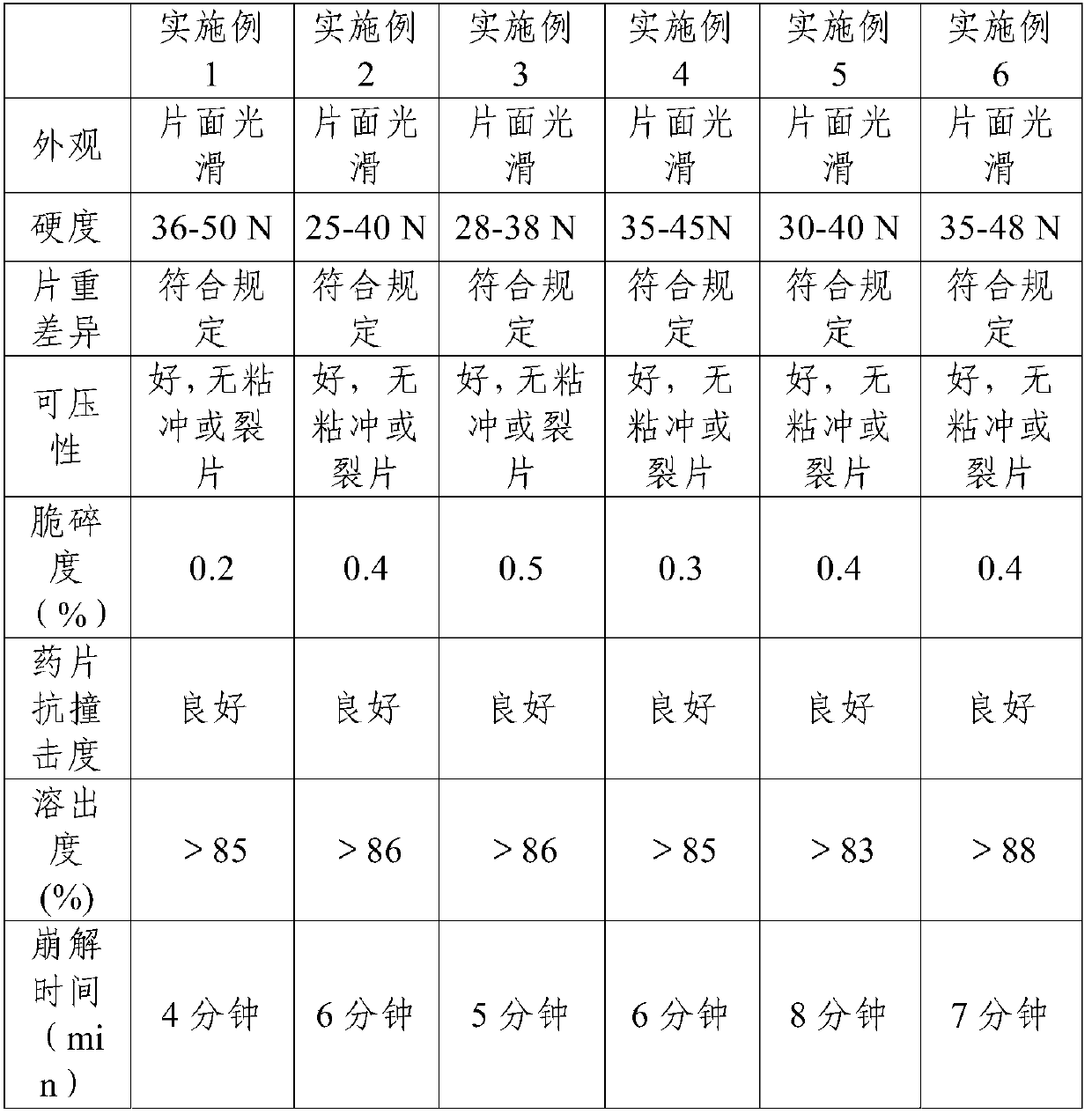

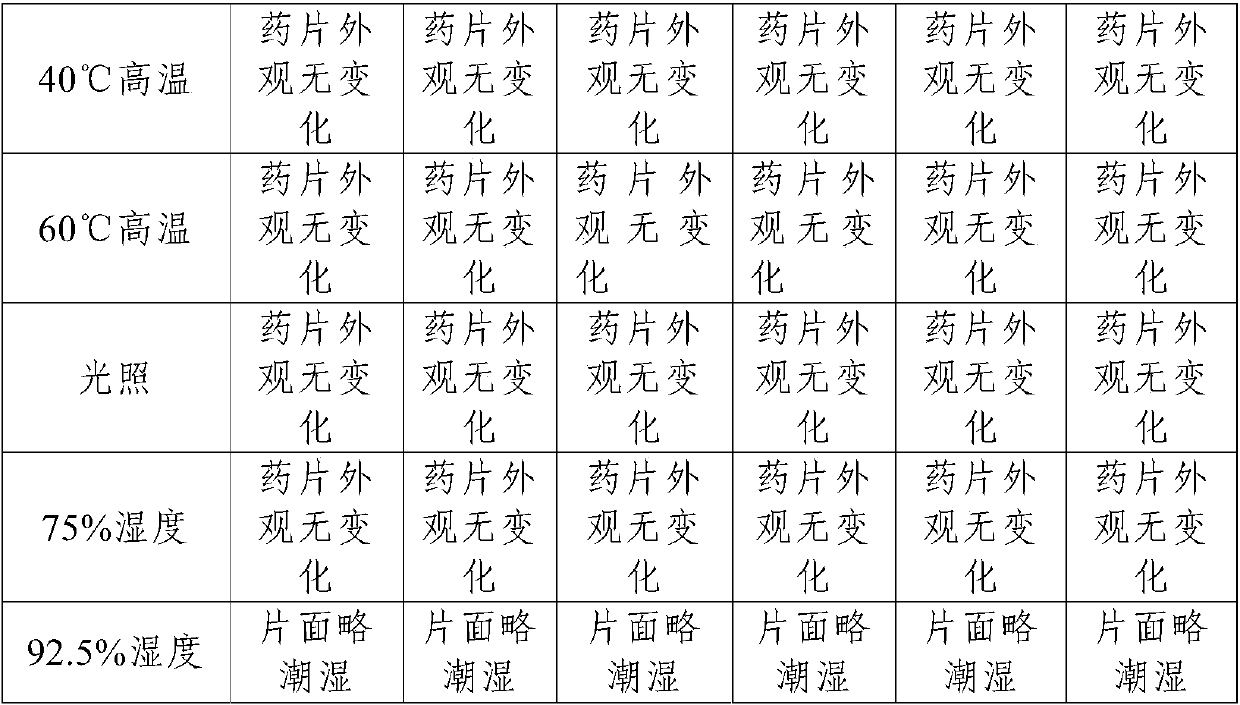

Examples

Embodiment 1

[0022] 1. Raw material and formula

[0023] Acetaminophen 0.5g;

[0024] Pregelatinized starch 0.05g;

[0025] Sodium carboxymethyl starch 0.01g;

[0026] Polyvinylpyrrolidone 0.0028g;

[0027] Starch 0.028g;

[0028] Stearic acid 0.004g.

[0029] 2. Preparation method

[0030] Consists of the following steps:

[0031] (1) each raw and auxiliary material is weighed for subsequent use;

[0032] (2) Paracetamol, pregelatinized starch, sodium carboxymethyl starch are mixed evenly;

[0033] (3) Make a soft material with a binder mixed with 10% starch slurry and 10% polyvinylpyrrolidone, granulate, and dry at 50°C;

[0034] The adhesive is prepared as follows: polyvinylpyrrolidone is dissolved in purified water to prepare a 10% solution, starch is prepared by a pulping method to prepare a 10% starch slurry, and the liquids prepared above are mixed.

[0035] (4) Add stearic acid, mix and compress into tablets.

Embodiment 2

[0037] 1. Raw material and formula

[0038] Acetaminophen 0.5g;

[0039] Pregelatinized starch 0.06g;

[0040] Sodium carboxymethyl starch 0.02g;

[0041] Polyvinylpyrrolidone 0.0028g;

[0042] Starch 0.028g;

[0043] Stearic acid 0.0012g.

[0044] 2. Preparation method

[0045] Consists of the following steps:

[0046] (1) each raw and auxiliary material is weighed for subsequent use;

[0047] (2) Paracetamol, pregelatinized starch, sodium carboxymethyl starch are mixed evenly;

[0048] (3) Make a soft material with a binder mixed with 10% starch slurry and 10% polyvinylpyrrolidone, granulate, and dry at 50°C;

[0049] The binder is prepared as follows: polyvinylpyrrolidone is dissolved in purified water to prepare a 10% solution, starch is prepared by a pulping method to prepare a 10% starch slurry, and the liquids prepared above are mixed.

[0050] (4) Add stearic acid, mix and compress into tablets.

Embodiment 3

[0052] 1. Raw material and formula

[0053] Acetaminophen 0.5g;

[0054] Pregelatinized starch 0.02g;

[0055] Sodium carboxymethyl starch 0.02g;

[0056] Polyvinylpyrrolidone 0.0028g;

[0057] Starch 0.028g;

[0058] Stearic acid 0.0012g.

[0059] 2. Preparation method

[0060] Consists of the following steps:

[0061] (1) each raw and auxiliary material is weighed for subsequent use;

[0062] (2) Paracetamol, pregelatinized starch, sodium carboxymethyl starch are mixed evenly;

[0063] (3) Make a soft material with a binder mixed with 10% starch slurry and 10% polyvinylpyrrolidone, granulate, and dry at 50°C;

[0064] The binder is prepared as follows: polyvinylpyrrolidone is dissolved in purified water to prepare a 10% solution, starch is prepared by a pulping method to prepare a 10% starch slurry, and the liquids prepared above are mixed.

[0065] (4) Add stearic acid, mix and compress into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com