Electricity-storage-device electrode, manufacturing method therefor, and electricity-storage device using said electrode

An electric storage device and electrode technology, applied in battery electrodes, batteries, circuits, etc., can solve the problems of inability to participate in electrode reactions, high solubility, and slow capacity reduction, and achieve improved electron transfer reactions, excellent energy density, and battery. The effect of improving the response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

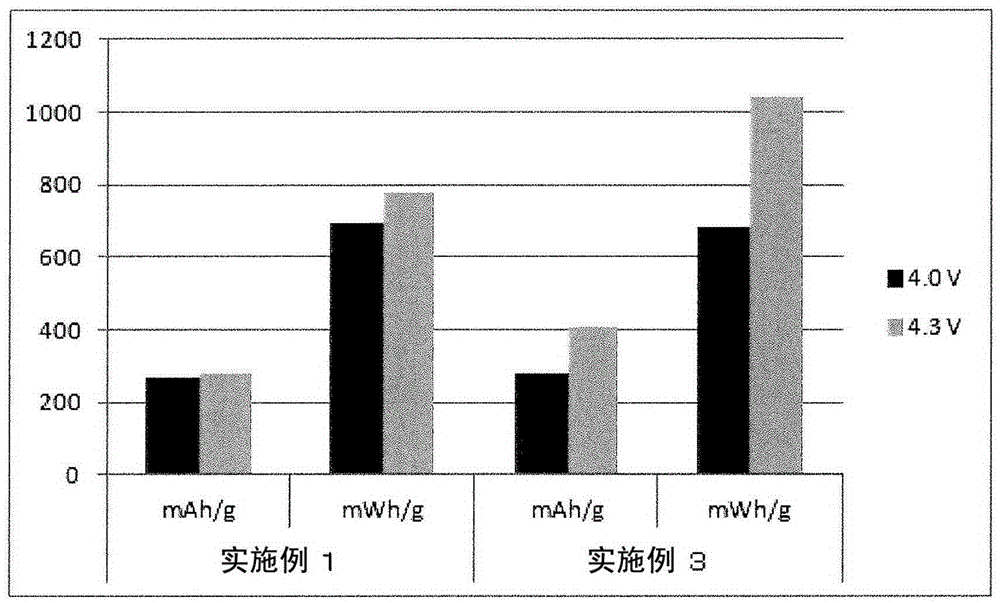

Embodiment 1

[0133]

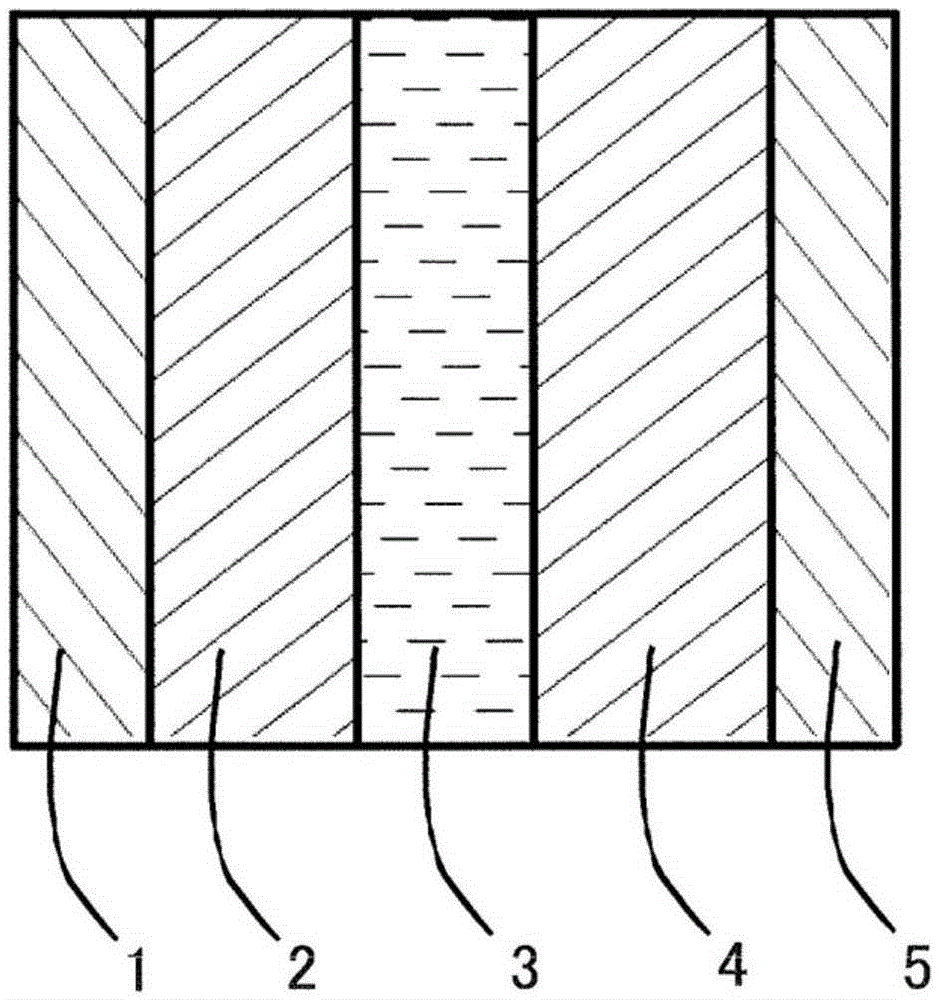

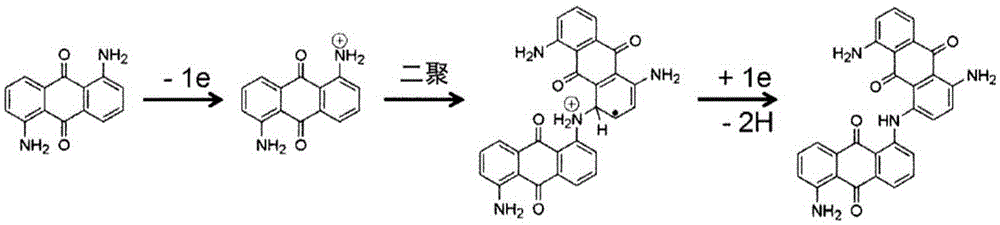

[0134] A composite active material obtained by mixing the polyaniline powder (A) and 1,5-diaminoanthraquinone (B) at a weight ratio (A:B) of 1:1, and acetylene black as a conductive additive (Denka Black, manufactured by Denki Kagaku Kogyo Co., Ltd.), and polytetrafluoroethylene (manufactured by DAIKININDUSTRIES, Ltd., F-302) as a binder, in terms of weight ratio, composite active material: conductive additive: binder is 10 After mixing in the ratio of :80:10 in an agate mortar, a composite electrode was formed on an aluminum mesh current collector by compression molding (4kN). The electrode layer has a thickness (excluding the current collector) of 700 to 800 μm and a weight of about 50 mg.

[0135] The above-mentioned positive electrode, negative electrode, and separator were all placed in a glove box immediately after being dried at 80° C. for 2 hours in a vacuum dryer. Then, the negative electrode, the separator, and the positive electrode were combined in this...

Embodiment 2 and 3

[0147] Next, compounding was carried out so that the weight ratio (A:B) of the polyaniline powder (A) and 1,5-diaminoanthraquinone (B) of the above-mentioned Example 1 was the ratio shown in Table 1, except Other than that, lithium secondary batteries of Examples 2 and 3 were produced in the same manner as in Example 1.

Embodiment 4

[0149] Except having replaced the (B) component of said Example 1 with 1, 4- diaminoanthraquinone, it carried out similarly to Example 1, and produced the lithium secondary battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com