Manufacturing method of carbon steel stainless steel double-metal polymerization pipe

A manufacturing method and technology of stainless steel, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of cracking of steel pipes, inability to guarantee thermal conductivity, stress concentration, etc., to improve adhesion problems and solve thermal conductivity problems. Sexually Undesirable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

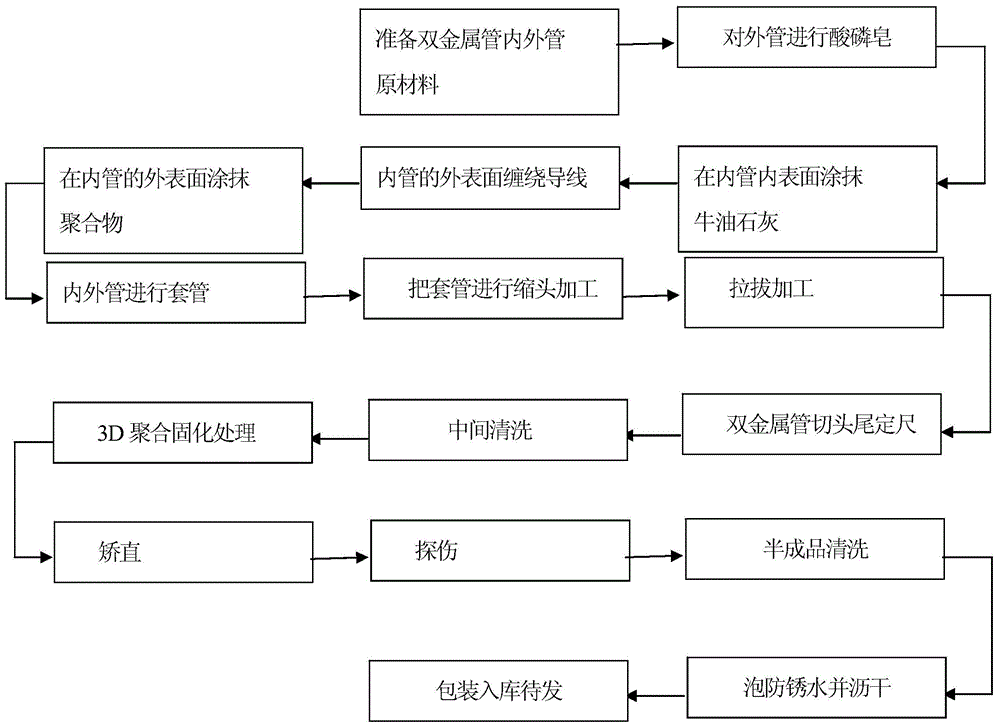

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for manufacturing a carbon steel stainless steel bimetallic polymer pipe. The inner layer of the bimetallic pipe is a stainless steel pipe and the outer layer is a carbon steel pipe. By winding a precious metal wire on the outer surface of the stainless steel inner pipe, and between the bimetallic materials Add the polymer layer material, and then closely aggregate the two layers of metal through the polymer layer curing process.

[0045](1) Prepare raw materials for inner and outer pipes of bimetallic steel pipes (carbon steel stainless steel polymer pipes)

[0046] The outer tube of bimetallic steel pipe (carbon steel stainless steel polymer tube) is made of precision seamless steel pipe made of E235 material that meets the requirements of EN10305-1 standard, and the specification is 35mm in outer diameter*wall thickness of 1.6mm; Stainless steel pipe, the specification is outer diameter 28mm*wall thickness 1.05mm. At the same time, ...

Embodiment 2

[0078] This embodiment provides a method for manufacturing a carbon steel stainless steel bimetallic polymer pipe. The inner layer of the bimetallic pipe is a stainless steel pipe and the outer layer is a carbon steel pipe. By winding a precious metal wire on the outer surface of the stainless steel inner pipe, and between the bimetallic materials Add the polymer layer material, and then closely aggregate the two layers of metal through the polymer layer curing process.

[0079] (1) Prepare raw materials for inner and outer pipes of bimetallic steel pipes (carbon steel stainless steel polymer pipes)

[0080] The outer tube of bimetallic steel pipe (carbon steel stainless steel polymer tube) adopts the precision seamless steel pipe of E235 material conforming to EN10305-1 standard, and the specification is outer diameter 28mm*wall thickness 1.5mm; the inner tube adopts 316 material conforming to ASTMA269 standard Stainless steel pipe, the specification is outer diameter 21mm*wa...

Embodiment 3

[0112] This embodiment provides a method for manufacturing a carbon steel stainless steel bimetallic polymer pipe. The inner layer of the bimetallic pipe is a stainless steel pipe and the outer layer is a carbon steel pipe. By winding a precious metal wire on the outer surface of the stainless steel inner pipe, and between the bimetallic materials Add the polymer layer material, and then closely aggregate the two layers of metal through the polymer layer curing process.

[0113] (1) Prepare raw materials for inner and outer pipes of bimetallic steel pipes (carbon steel stainless steel polymer pipes)

[0114] The outer tube of bimetallic steel pipe (carbon steel stainless steel polymer tube) adopts the precision seamless steel pipe of E235 material conforming to EN10305-1 standard, and the specification is outer diameter 26mm*wall thickness 1mm; the inner tube adopts 316 stainless steel material conforming to ASTMA269 standard Tube, the specification is outer diameter 20mm* wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com