Method for preparing metal glass coating by utilizing electrical sparkle deposition process

A technology of EDM deposition and metallic glass, which is applied in coating, metal material coating process, etc., can solve the problems of low glass forming ability and difficult preparation, and achieve the effect of flexible use, simple equipment and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

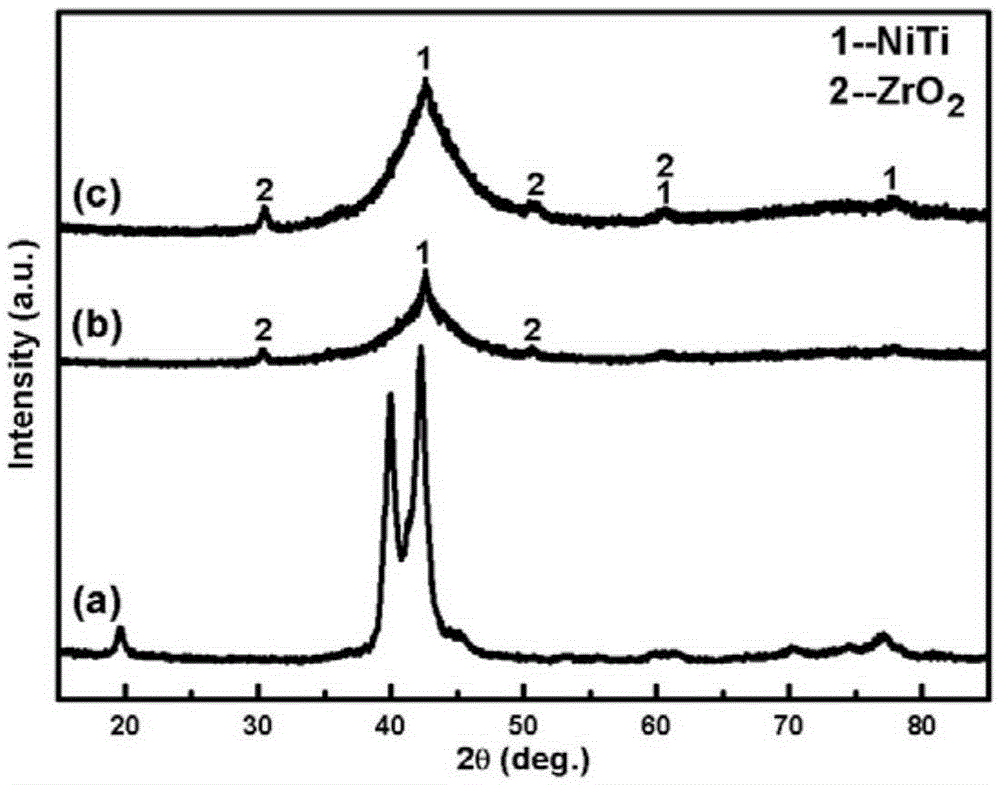

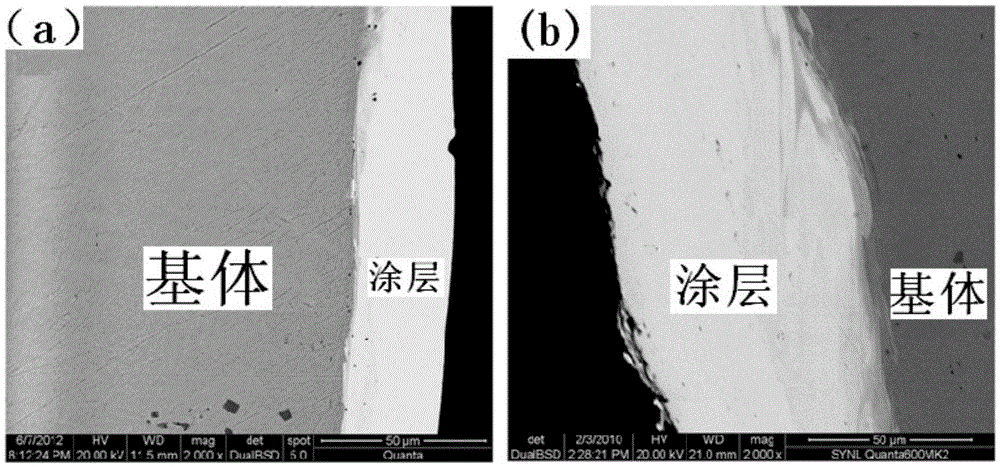

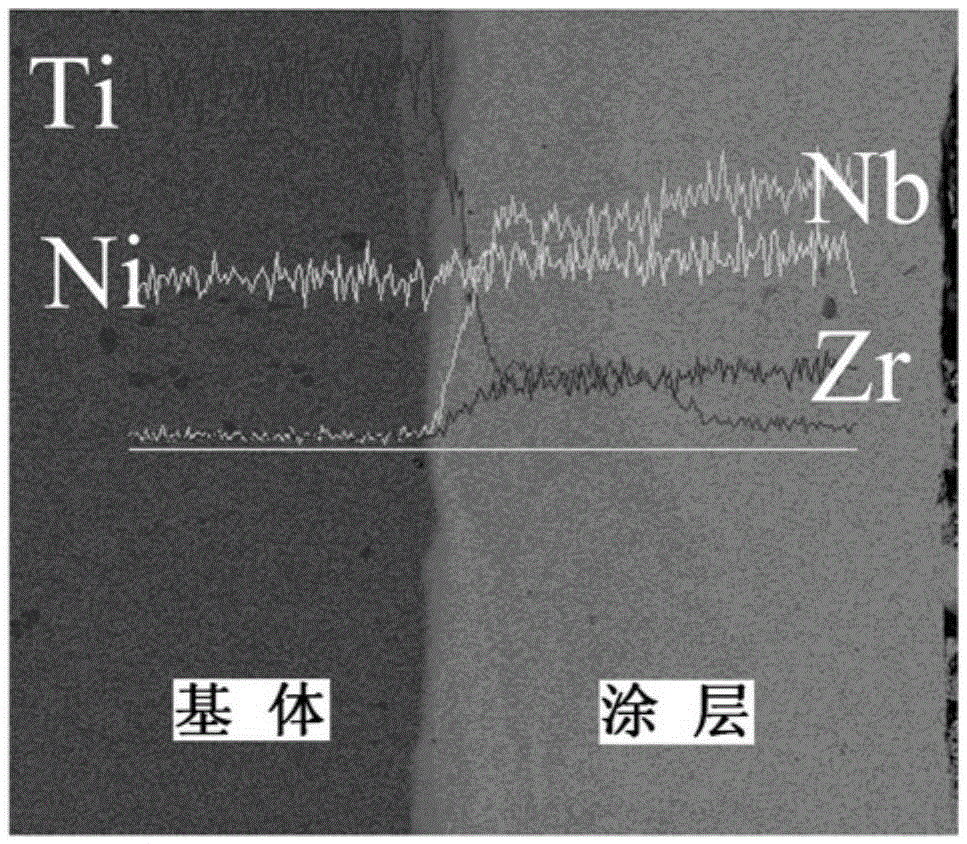

[0055] Preparation of Ni on Ti-Ni Matrix Alloy 53 Nb 20 Ti 10 Zr 8 co 6 Cu 3 coating

[0056] The equipment used is SparkDepoMODEL500 type electric spark deposition equipment; the working parameters are set as: voltage 50V, capacitance 80μF, discharge frequency 2000Hz, and then turn on the discharge switch, so that the front electrode of the welding torch is in slight contact with the substrate, spark discharge is generated between the two, and the electrode The material is melted and sputtered onto the surface of the substrate to form "coating spots" one by one; while discharging, the welding torch and the substrate maintain relative motion, and the "coating spots" form a continuous coating through connection and superposition. When working, the electrode rotates at a speed of 800 revolutions per second under the action of the chuck's rotation, and at the same time, a protective gas flows through the protective cover; the flow rate of the protective gas is 25 milliliters...

Embodiment 2

[0059] Preparation of Ni on Ti-Ni Matrix Alloy 61.5 Nb 33.5 Zr 5 coating

[0060] The equipment used is SparkDepoMODEL500 type electric spark deposition equipment; the working parameters are set as: voltage 65V, capacitance 35μF, discharge frequency 2000Hz, and then turn on the discharge switch, so that the front electrode of the welding torch is in slight contact with the substrate, spark discharge is generated between the two, and the electrode The material is melted and sputtered onto the surface of the substrate to form "coating spots" one by one; while discharging, the welding torch and the substrate maintain relative motion, and the "coating spots" form a continuous coating through connection and superposition. When working, the electrode rotates at a speed of 500 revolutions per second under the action of the chuck, and at the same time, a protective gas flows through the protective cover; the flow rate of the protective gas is 75 milliliters per second.

[0061] Aft...

Embodiment 3

[0063] Preparation of Ni on Ti-Ni Matrix Alloy 61.5 Nb 33.5 Zr 5 coating

[0064] The equipment used is SparkDepoMODEL500 type electric spark deposition equipment; the working parameters are set as: voltage 150V, capacitance 10μF, discharge frequency 2000Hz, and then turn on the discharge switch, so that the front electrode of the welding torch is in slight contact with the substrate, spark discharge is generated between the two, and the electrode The material is melted and sputtered onto the surface of the substrate to form "coating spots" one by one; while discharging, the welding torch and the substrate maintain relative motion, and the "coating spots" form a continuous coating through connection and superposition. When working, the electrode rotates at a speed of 800 revolutions per second under the action of the chuck's rotation, and at the same time, a protective gas flows through the protective cover; the flow rate of the protective gas is 25 milliliters per second. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com