Method for increasing erythromycin fermentation titer

A technology of erythromycin and titer, which is applied in the field of improving the fermentation titer of erythromycin, can solve the problems of lack of dissolved oxygen, reduced dissolved oxygen concentration, and lack of dissolved oxygen in bacteria, so as to increase the vitality of bacteria and improve the level of fermentation. , the effect of prolonging the secretion period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Preparation method: use three-stage fermentation to produce erythromycin, and the specific steps are as follows:

[0019] 1. Preparation of slant spores: Inoculate Saccharopolyspora rubrum on a solid medium under aseptic conditions, culture at a constant temperature of 35°C for 6-8 days, and inoculate in a primary seed medium.

[0020] 2. The above slant spore culture medium was prepared according to conventional methods, and the formula was: starch 8g / L, ammonium sulfate 2.5g / L, sodium chloride 2.3g / L, calcium carbonate 2.4g / L, corn steep liquor 1.0g / L.

[0021] 3. First-level seed cultivation: Inoculate the slant spores grown in step 1 into the first-level seed medium in an aseptic manner, and cultivate at a constant temperature of 35°C with an aeration ratio of 1.5-2.0v / v / min and a stirring speed of 400-600r / min, cultivated for 40-60 hours.

[0022] 4. The above-mentioned primary seed culture medium is prepared by a conventional method, and its formula is starch 10...

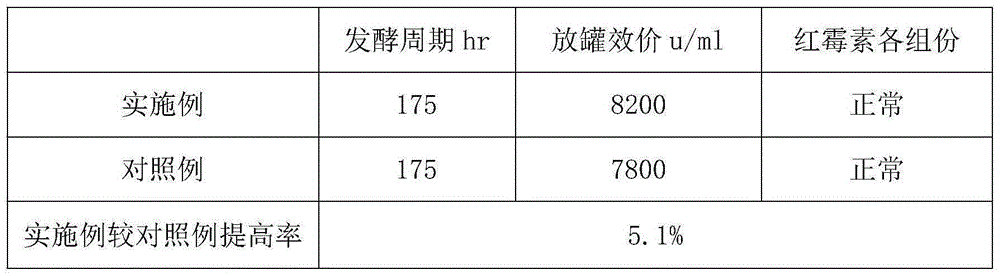

Embodiment 1

[0030] 1. Take the secondary seed medium cultivated in step 5 of the above preparation method and inoculate it in the embodiment fermentation medium prepared in step 7 under aseptic conditions, cultivate according to normal culture conditions, and start to slowly add ammonium sulfate after fermentation until 60 hours solution, the concentration of the ammonium sulfate solution is 3-5%, and the feed rate per hour is controlled at 120-250L / hr according to the viscosity and the dissolved oxygen situation, and the feed rate is stopped at 140 hours, and the cumulative feed rate is 5% of the fermentation broth volume. -8%.

[0031] 2. Take the secondary seed medium cultured in step 5 of the above preparation method and inoculate it in the normal control fermentation medium prepared in step 7 under aseptic conditions, cultivate according to the normal culture conditions, and stop fermentation after 175 hours.

[0032]

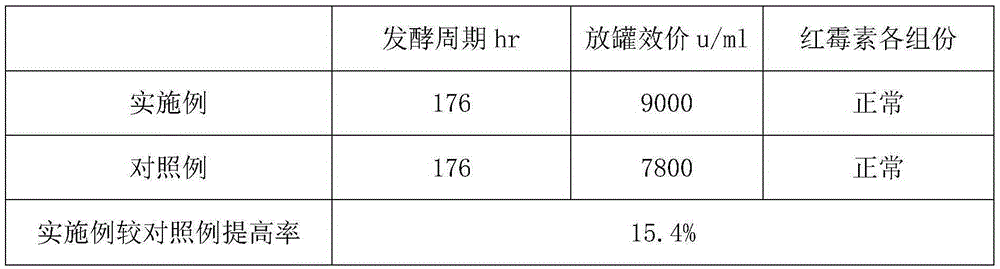

Embodiment 2

[0034] 1. Take the secondary seed medium cultivated in step 5 of the above preparation method and inoculate it in the embodiment fermentation medium prepared in step 7 under aseptic conditions, cultivate according to normal culture conditions, and start to slowly add ammonium sulfate after fermentation until 60 hours Solution, the concentration of the ammonium sulfate solution is 6%, the feed rate per hour is controlled at 120-200L / hr according to the viscosity and the dissolved oxygen situation, and the feed rate is stopped at 140 hours, and the cumulative feed rate is 5-8% of the fermentation broth volume. %.

[0035] 2. Take the secondary seed medium cultured in step 5 of the above preparation method and inoculate it in the normal control fermentation medium prepared in step 7 under aseptic conditions, cultivate according to the normal culture conditions, and stop fermentation after 175 hours.

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com