Porous polymer material used for preparing supercapacitor electrode and preparation method thereof

A technology of porous polymer and supercapacitor, applied in the field of material science, to achieve the effect of simple preparation method, improved specific capacitance and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

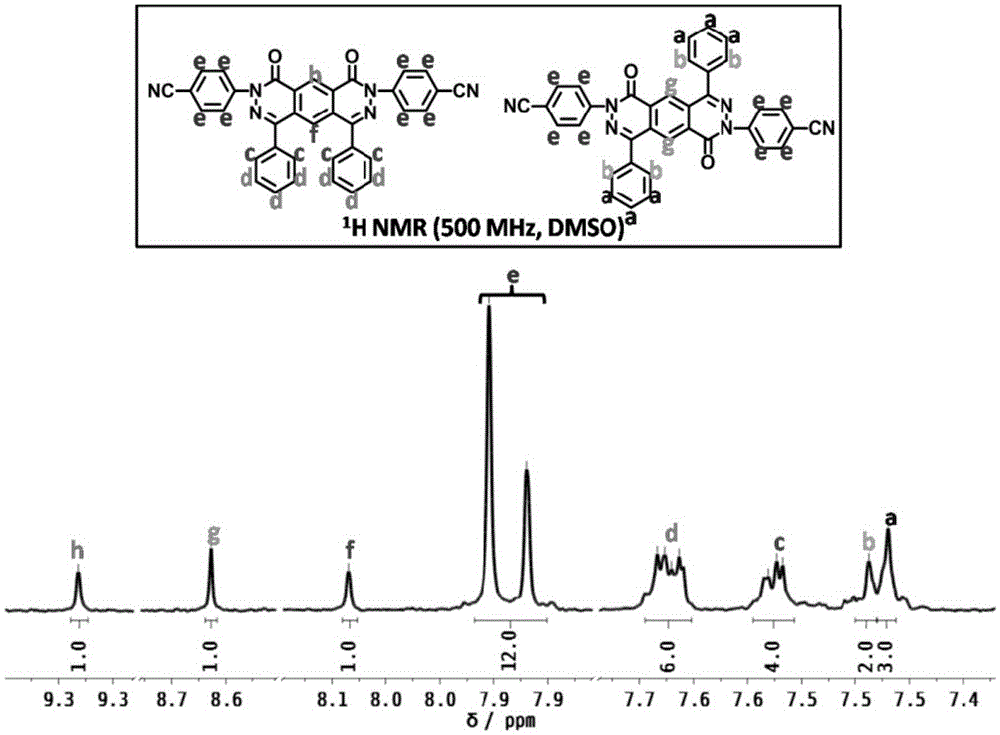

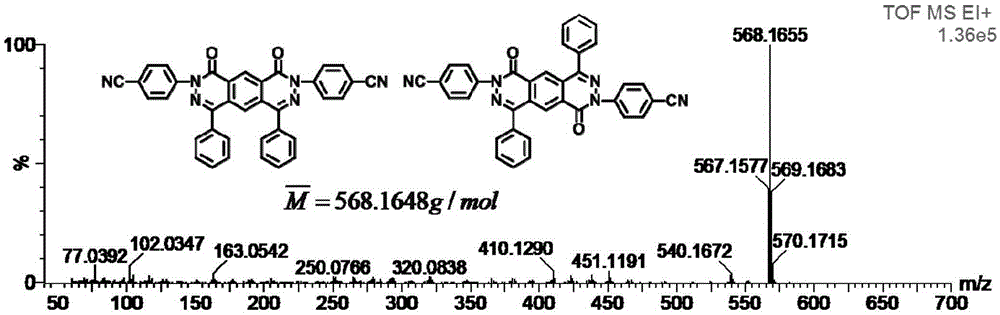

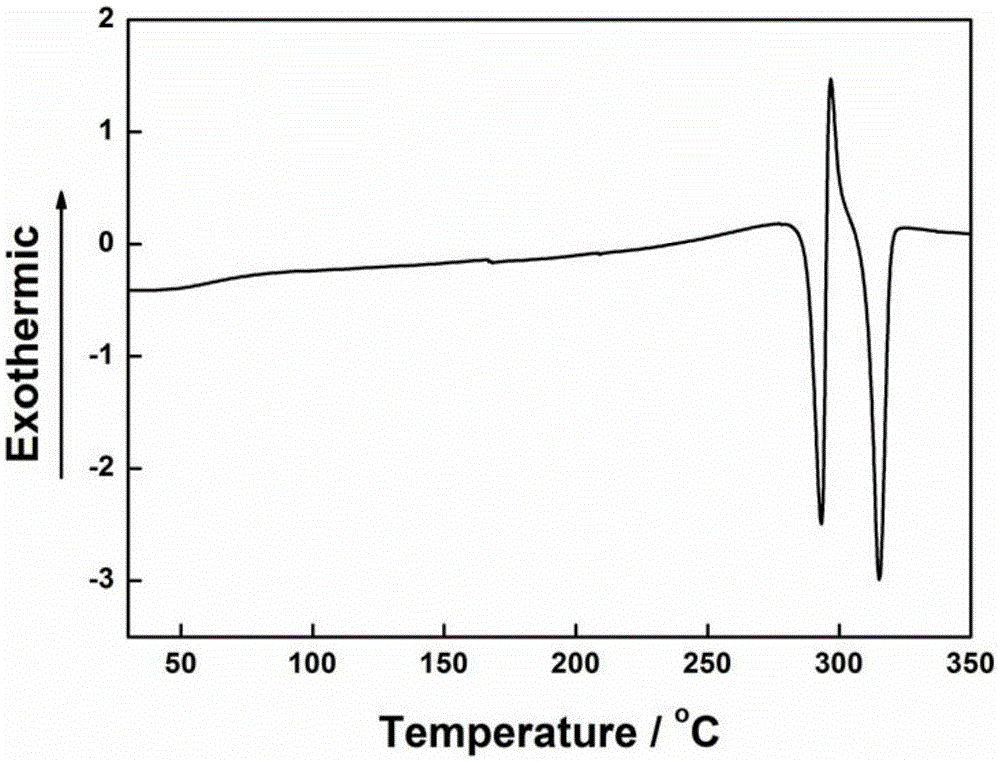

[0047] The first step, the preparation of a novel dinitrile monomer containing a bisdiazinone structure

[0048] Add compound 1a (37g) (structural formula such as figure 1 Shown), 4-fluorobenzonitrile (30g), cesium fluoride (37g), then add 100ml of dimethyl sulfoxide DMSO to it, stir, react at 150°C for 5h, sink the solution into ethanol, Stand still, suction filter, Soxhlet extraction, and dry to obtain a yellow powdery solid. Product characterization as attached figure 1 ~ attached Figure 4 shown.

[0049] The second step, the preparation of porous polymer containing phthalazinone and s-triazine structure

[0050] Put the new dinitrile monomer (0.5g) containing bisdiazinone structure and anhydrous zinc chloride (0.2g) into a quartz tube, vacuum seal the tube, polymerize at 500°C for 30h, and cool the furnace to room temperature , take it out, put the obtained product in 5% dilute hydrochloric acid, ultrasonic 1-2h, centrifuge, wash with deionized water to neutrality, f...

Embodiment 2

[0056] The first step, the preparation of a novel dinitrile monomer containing a bisdiazinone structure

[0057] As described in Example 1.

[0058] The second step, the preparation of the polymer containing phthalazinone and s-triazine structure

[0059] The polymerization temperature was changed to 550° C., and other processing conditions were the same as in Example 1. Finally, a polymer polymerized at 550°C was obtained.

[0060] The specific Raman spectrum of the product obtained is shown in the appendix Figure 5 . Infrared spectrum see attached Figure 6 . Nitrogen adsorption and desorption curves and pore size distribution refer to the attached Figure 7 .

[0061] In order to further verify its electrical properties, electrochemical performance tests were carried out.

[0062] As described in Example 1.

[0063] The change of the specific capacity of the electrode material with the current density and the AC impedance spectrum can be found in the appendix Fi...

Embodiment 3

[0065] The first step, the preparation of a novel dinitrile monomer containing a bisdiazinone structure

[0066] As described in Example 1.

[0067] The second step, the preparation of the polymer containing phthalazinone and s-triazine structure

[0068] The polymerization temperature was changed to 600° C., and other processing conditions were the same as in Example 1. Finally, a polymer polymerized at 600°C was obtained.

[0069] The specific Raman spectrum of the product obtained is shown in the appendix Figure 5 . Infrared spectrum see attached Figure 6 . Nitrogen adsorption and desorption curves and pore size distribution refer to the attached Figure 7 . For the high-resolution TEM spectrum and the distribution labels of carbon atoms, nitrogen atoms, and oxygen atoms, please refer to the attached Figure 8 .

[0070] In order to further verify its electrical properties, electrochemical performance tests were carried out.

[0071] As described in Example 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com