Preparation method of cyanoacetic acid and derivatives thereof

A technology of cyanoacetic acid and sodium cyanoacetate, applied in the field of preparation of cyanoacetic acid and derivatives thereof, can solve the problems of complicated operation, high cost, large amount of organic solvent, etc., and achieves simple operation, low production cost, and less amount of three wastes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

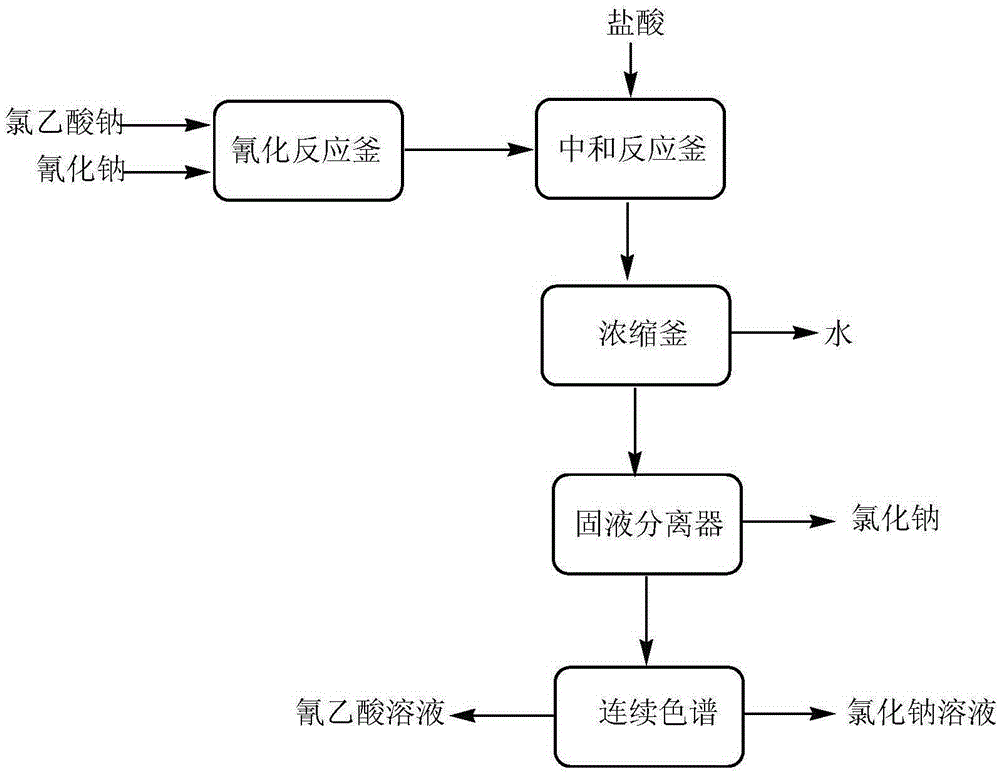

[0025] refer to figure 1 , the present invention is further described:

[0026] (1) Cyanide reaction: 96.8g of chloroacetic acid (content 98%, 1.0mol) and 70g of water were stirred and dissolved, and neutralized to pH=6.5-7.0 with 25% aqueous sodium carbonate solution (215g), generating sodium chloroacetate 354.8 g (content 32.8%); be warming up to 50 ℃, then dropwise add 165.0g (1.01mol) of sodium cyanide aqueous solution of mass concentration 30%, when the reaction temperature reaches 85-90 ℃, stop heating and start cooling, when the reaction temperature When the temperature reaches 105°C, the reaction is completed, and cooled to room temperature to obtain an aqueous solution of sodium cyanoacetate;

[0027] (2) Acidification reaction: add mass concentration 30% hydrochloric acid (127.8g, 1.05mol) to the aqueous sodium cyanoacetate solution obtained in step (1) to acidify to obtain 495.1g of a mixture containing cyanoacetic acid and sodium chloride;

[0028] (3) Distilled ...

Embodiment 2

[0032] (1) Cyanide reaction: 96.8g of chloroacetic acid (content 98%, 1.0mol) and 70g of water were stirred and dissolved, and neutralized to pH=6.5-7.0 with 25% aqueous sodium carbonate solution (215g), generating sodium chloroacetate 354.8 g (content 32.8%); be warming up to 50 ℃, then dropwise add 179.7g (1.1mol) of sodium cyanide aqueous solution of mass concentration 30%, when the reaction temperature reaches 85-90 ℃, stop heating and start cooling, when the reaction temperature When the temperature reaches 105°C, the reaction is completed, and cooled to room temperature to obtain an aqueous solution of sodium cyanoacetate;

[0033] (2) Acidification reaction: add mass concentration 33% hydrochloric acid (110.6g, 1.0mol) to the sodium cyanoacetate aqueous solution obtained in step (1) to acidify to obtain 474.9g of a mixture containing cyanoacetic acid and sodium chloride;

[0034](3) Distilled water desalination: turn on vacuum, control the vacuum degree of the system to...

Embodiment 3

[0038] (1) Cyanide reaction: 96.8g of chloroacetic acid (content 98%, 1.0mol) and 70g of water were stirred and dissolved, and neutralized to pH=6.5-7.0 with 25% aqueous sodium carbonate solution (215g), generating sodium chloroacetate 354.8 g (content 32.8%); be warming up to 50 ℃, then dropwise add 171.5g (1.05mol) of sodium cyanide aqueous solution of mass concentration 30%, when the reaction temperature reaches 85-90 ℃, stop heating and start cooling, when the reaction temperature When the temperature reaches 105°C, the reaction is completed, and cooled to room temperature to obtain an aqueous solution of sodium cyanoacetate;

[0039] (2) Acidification reaction: add mass concentration 36% hydrochloric acid (111.5g, 1.1mol) to the sodium cyanoacetate aqueous solution obtained in step (1) to acidify to obtain 439.8g of a mixture containing cyanoacetic acid and sodium chloride;

[0040] (3) Distilled water desalination: turn on the vacuum, control the vacuum degree of the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com