Modified attapulgite preparation method

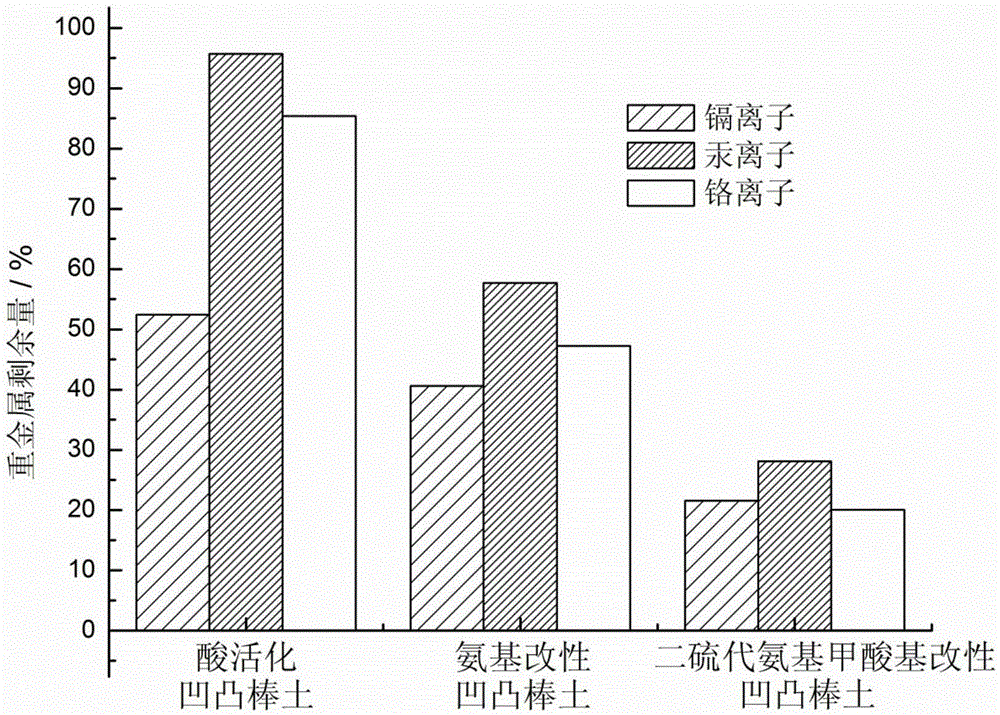

A technology for modifying attapulgite and attapulgite, which is applied in chemical instruments and methods, restoration of polluted soil, and other chemical processes, and can solve problems such as small amount of sulfhydryl groups, increased cost, and influence on adsorption effect, and achieves Improve adsorption selectivity, reduce treatment cost, and prevent secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of modified attapulgite, which comprises the steps of:

[0022] (1) After attapulgite is pulverized, sieve through a 100-150 mesh sieve;

[0023] (2) Mix the undersize with a 20% hydrochloric acid solution in a mass ratio of 1:20-100, stir at a constant temperature of 60-80°C for at least 4 hours, then filter, wash with water, and dry to obtain acid-activated attapulgite;

[0024] (3) Mix acid-activated attapulgite, solvent and amino compound evenly according to the mass ratio of 1:50:0.4-2, stir at room temperature for 12 hours, heat to solvent reflux and maintain for more than 4 hours, and filter the mixture after cooling to room temperature , washing with ethanol, and drying to obtain amino-modified attapulgite;

[0025] (4) Mix the amino-modified attapulgite, carbon disulfide and tetrahydrofuran according to the mass ratio of 1:0.3-1.5:50 and place them in an ice bath environment, add alkaline reagents, amino-modified attapulgite and the added...

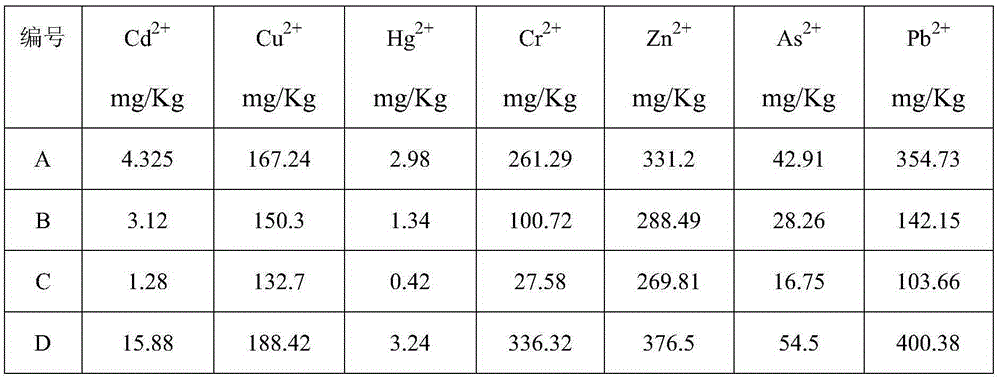

Embodiment 1

[0031] a) Attapulgite is crushed and passed through a 100-mesh sieve.

[0032] b) Mix the undersize with 20% by mass hydrochloric acid solution according to the mass ratio of 1:100 and disperse evenly, stir at 60°C for at least 4 hours; filter, wash with water, and dry to obtain acid-activated attapulgite .

[0033] c) Mix acid-activated attapulgite, toluene and 3-aminopropyltriethoxysilane in a mass ratio of 1:50:1.2, stir at room temperature for 12 hours, then heat to toluene reflux and maintain for 4 hours. After the mixture was cooled to room temperature, it was filtered, washed with ethanol, and dried to obtain amino-modified attapulgite.

[0034] d) Mix the amino-modified attapulgite, carbon disulfide and tetrahydrofuran according to the mass ratio of 1:0.9:50 and place it in an ice bath environment, add sodium hydroxide, the mass of the amino-modified attapulgite and the added sodium hydroxide The ratio is 1:2. Rapidly heated to reflux, refluxed for 2 hours, filtered...

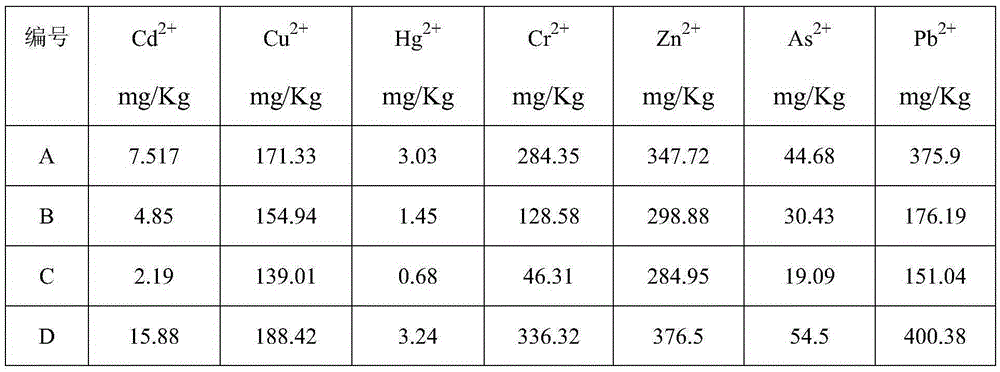

Embodiment 2

[0042] (1) Preparation of dithiocarbamate-based adsorbent

[0043] a) Attapulgite is crushed and passed through a 120-mesh sieve.

[0044] b) Mix the undersize with 20% by mass hydrochloric acid solution according to the mass ratio of 1:60 and disperse evenly, stir at 70°C for at least 4 hours; filter, wash with water, and dry to obtain acid-activated attapulgite .

[0045] c) Mix acid-activated attapulgite, benzene and 3-aminopropyltriethoxysilane in a mass ratio of 1:50:0.8, stir at room temperature for 12 hours, then heat to benzene reflux and maintain for 5 hours. After the mixture was cooled to room temperature, it was filtered, washed with ethanol, and dried to obtain amino-modified attapulgite.

[0046] d) Mix amino-modified attapulgite, carbon disulfide and tetrahydrofuran according to the mass ratio of 1:0.6:50 and place them in an ice bath environment, add sodium hydride, the mass ratio of amino-modified attapulgite to added sodium hydride is 1:1. Rapidly heated to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com