Alprostadil injection and preparation method thereof

A technology of dil injection and alprostadil, which can be used in pharmaceutical formulations, emulsion delivery, and medical preparations containing active ingredients, etc., can solve problems such as cumbersome processes, reduced drug stability, and increased growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

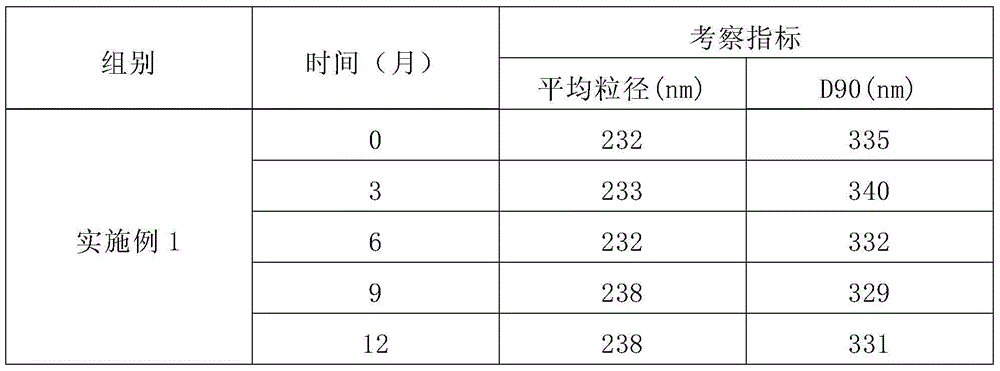

Embodiment 1

[0082] 1) Under the protection of nitrogen, add 18g of egg yolk lecithin and 1.2g of oleic acid into 100g of soybean oil, heat to 60°C, and stir at 4000 rpm to dissolve.

[0083] 2) Take 5 mg of alprostadil, dissolve it with 0.3 ml of absolute ethanol, add it into soybean oil and shear and dissolve it as the oil phase.

[0084] 3) Add 22.1 g of glycerol, an isotonic agent, into 300 ml of water for injection, heat to 60° C. and stir to dissolve, as the water phase.

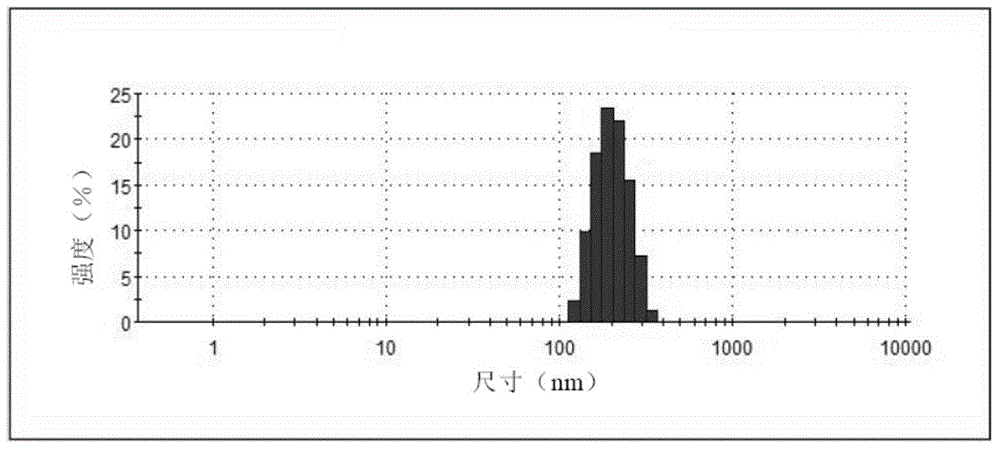

[0085] 4) The above-mentioned oil phase and water phase are respectively added through a peristaltic pump, the oil phase addition speed is 10g / min, the water phase addition speed is 30g / min, sheared by an online shearing machine, the shear line speed is 40m / s, and water for injection is adjusted. The total amount reaches 1000ml to obtain colostrum. The colostrum is transferred to a high-pressure homogenizer and homogenized several times under a pressure of 1000 bar to obtain essence milk. Adjust the pH to 5.0-6.0...

Embodiment 2

[0087] 1) Under the protection of nitrogen, add 18g of egg yolk lecithin and 1.2g of oleic acid into 100g of soybean oil, heat to 60°C, and stir at 4000 rpm to dissolve.

[0088] 2) Take 5 mg of alprostadil, dissolve it with 0.3 ml of absolute ethanol, add it into soybean oil and shear and dissolve it as the oil phase.

[0089] 3) Add 22.1 g of glycerol, an isotonic agent, into 400 ml of water for injection, heat to 60° C. and stir to dissolve, as the water phase.

[0090] 4) The above-mentioned oil phase and water phase are respectively added through a peristaltic pump, the oil phase addition speed is 10g / min, the water phase addition speed is 40g / min, sheared by an online shearing machine, the shear line speed is 40m / s, and water for injection is adjusted. The total amount reaches 1000ml to obtain colostrum. The total amount of water for injection was adjusted to 1000ml, and the colostrum was transferred to a high-pressure homogenizer and homogenized several times under a p...

Embodiment 3

[0092] 1) Under the protection of nitrogen, add 18g of egg yolk lecithin and 1.2g of oleic acid into 100g of soybean oil, heat to 60°C, and stir at 4000 rpm to dissolve.

[0093] 2) Take 5 mg of alprostadil, dissolve it with 0.3 ml of absolute ethanol, add it into soybean oil and shear and dissolve it as the oil phase.

[0094] 3) Add 22.1 g of glycerol, an isotonic agent, into 500 ml of water for injection, heat to 60° C. and stir to dissolve, as the water phase.

[0095] 4) The above-mentioned oil phase and water phase were added through a peristaltic pump respectively, the oil phase was added at a speed of 10g / min, and the water phase was added at a speed of 50g / min, sheared by an online shearing machine, the shear line speed was 40m / s, and water for injection was adjusted. The total amount reaches 1000ml to obtain colostrum. The colostrum is transferred to a high-pressure homogenizer and homogenized several times under a pressure of 1000 bar to obtain essence milk. Adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com