Synthetic method for basic ionic liquid

A technology of ionic liquid and synthesis method, applied in the direction of organic chemistry, can solve the problems of complex catalyst preparation, poor strength, impurity pollution, etc., achieve high catalytic efficiency and reusability, simple synthesis method, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

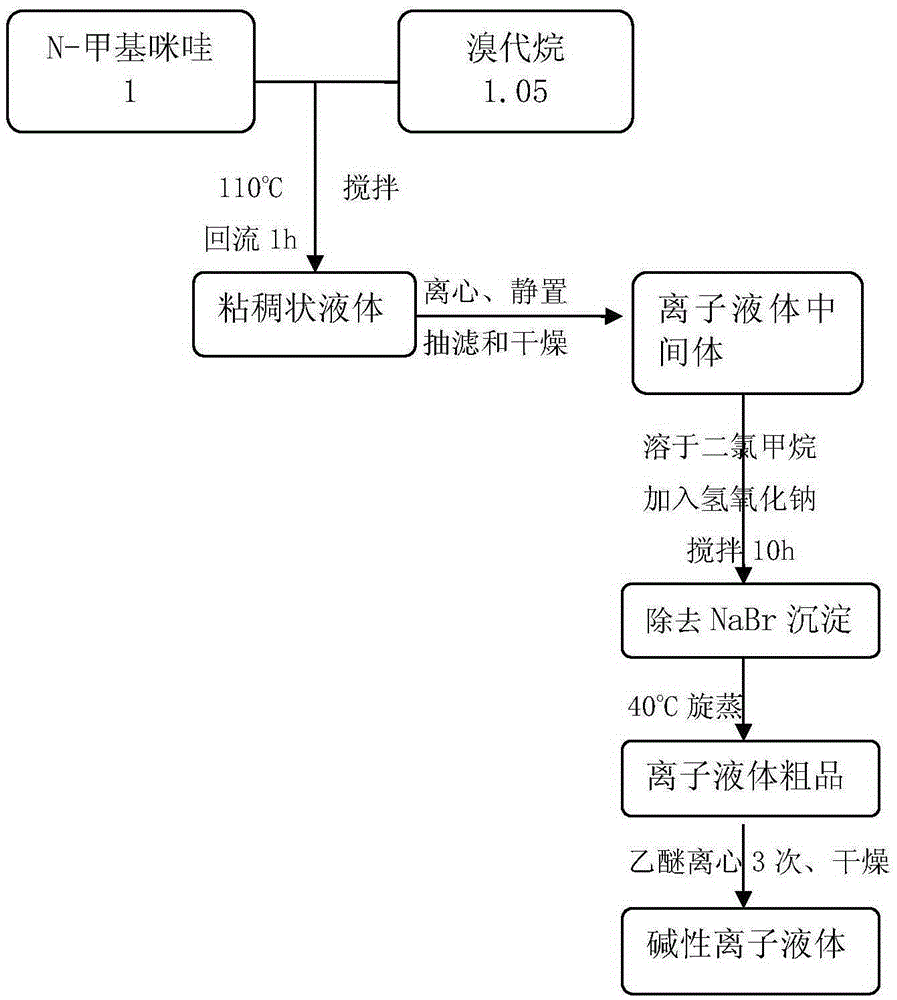

[0014] Step 1: Add N-methylimidazole and n-butane bromide into a three-necked flask at a molar ratio of 1:1.05, stir magnetically at 110°C, condense and reflux for 1 hour, and obtain a light yellow viscous liquid [Bmim]Br. The liquid crude product was washed 3 times with ethyl acetate, distilled under reduced pressure, added acetone, oscillated to dissolve, added a small amount of seed crystals, allowed to stand for 2-3 hours, and [Bmim]Br was crystallized, and the acetone was separated by suction filtration to obtain high-purity The intermediate [Bmim]Br was dried in a vacuum oven at 70°C until constant weight.

[0015] The second step: the synthesis of basic ionic liquid [Bmim]oH, take an appropriate amount of ionic liquid intermediate [Bmim]Br dissolved in 50ml of dichloromethane, add equimolar granular solid sodium hydroxide, stir at room temperature for 10h , remove the NaBr precipitate by suction filtration, remove the solvent by rotary evaporation at 40°C, and obtain th...

Embodiment 2

[0017] [Emim][Ac] can be obtained by changing the brominated alkanes bromobutane to bromoethane, and other steps and conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com