A supercapacitor electrode material having a large working potential window and a preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of small working potential window, complex process and high production cost, and achieves overcoming bottleneck value and stability. Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare as follows:

[0024] (1) Set 90PPI and surface density to 220g / m 2 1. 1.6mm thick nickel foam, when the pressure is 1MPa, the pressure holding time is 1min, and then placed in 5% dilute hydrochloric acid to ultrasonically clean for 5min, and then alternately washed with dehydrated and absolute ethanol three times each, and placed in a vacuum oven at 50°C Drying in medium for 12h to obtain foamed nickel substrate;

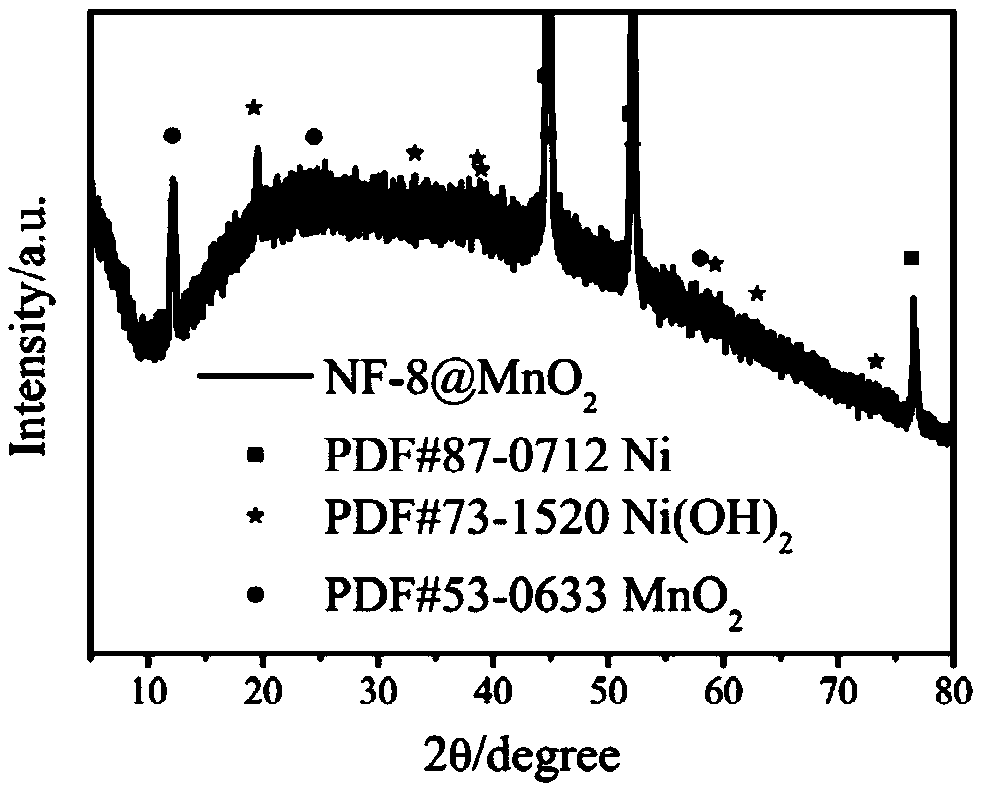

[0025] (2) Place the foamed nickel substrate obtained in step (1) in a stainless steel kettle with polytetrafluoroethylene as the inner liner, and conduct a hydrothermal reaction for 8 hours at a water-to-air volume ratio of 7:3 and 180°C. After washing with water, After drying in air at 80°C for 6 hours, the morphology of the nickel foam substrate was obtained as follows: figure 1 The material of the array of hexagonal nickel hydroxide flakes shown in the SEM image of ;

[0026] (3) the nickel foam obtained in step (2) is the material of the hexag...

Embodiment 2

[0031] Prepare as follows:

[0032] (1) Set 110PPI and surface density to 320g / m 2 1.8mm thick nickel foam, when the pressure is 1MPa, the pressure holding time is 2min, and then placed in 5% dilute hydrochloric acid to ultrasonically clean for 5min, and then alternately washed with dehydrated and absolute ethanol three times each, and placed in a vacuum oven at 50°C Drying in medium for 12h to obtain foamed nickel substrate;

[0033] (2) Place the foamed nickel substrate obtained in step (1) in a stainless steel kettle with polytetrafluoroethylene as the inner liner, and perform a hydrothermal reaction for 16 hours at a water-to-air volume ratio of 3:2 and 185°C. After washing with water, Dry in air at 80°C for 6 hours to obtain the material of hexagonal nickel hydroxide flake array based on nickel foam;

[0034] (3) the foamed nickel obtained in the step (2) is the material of the hexagonal nickel hydroxide sheet array as the base as the working electrode, the platinum sheet...

Embodiment 3

[0039] Prepare as follows:

[0040] (1) Set 110PPI and surface density to 320g / m 2 1.8mm thick nickel foam, when the pressure is 1MPa, the pressure holding time is 2min, and then placed in 5% dilute hydrochloric acid to ultrasonically clean for 5min, and then alternately washed with dehydrated and absolute ethanol three times each, and placed in a vacuum oven at 50°C Drying in medium for 12h to obtain foamed nickel substrate;

[0041] (2) Place the foamed nickel substrate obtained in step (1) in a stainless steel kettle with polytetrafluoroethylene as the liner, and perform a hydrothermal reaction for 24 hours at a water-to-air volume ratio of 4:1 and 175°C. After washing with water, Dry in air at 100°C for 6 hours to obtain a hexagonal nickel hydroxide flake array material based on nickel foam;

[0042] (3) the foamed nickel obtained in the step (2) is the material of the hexagonal nickel hydroxide sheet array as the base as the working electrode, the platinum sheet of equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com