Method for preparing C5, C6 alkane by converting acidic biomass-based sugar alcohol solution

An acidic sugar alcohol, biomass technology, applied in the field of catalysis, can solve the problems of catalyst development and application obstacles, poor catalyst stability, aluminum loss, etc., to achieve good reactivity and stability, strong selective adsorption performance, strong hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

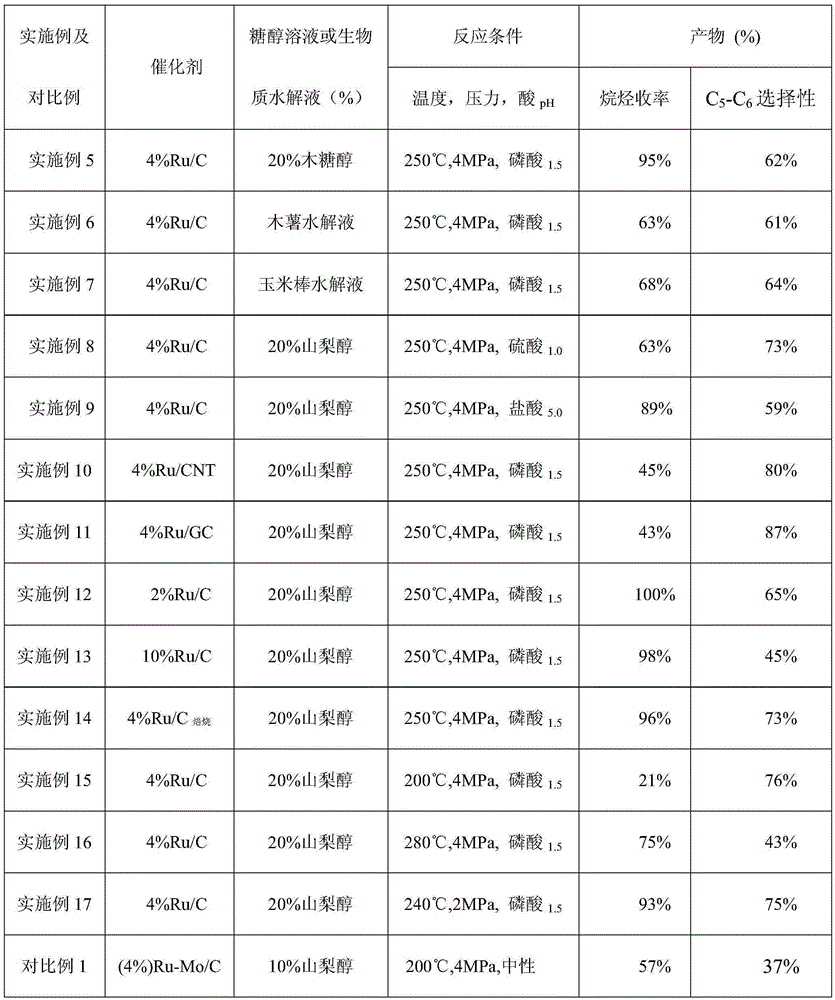

Examples

Embodiment 1

[0031] A method for converting acidic biomass-based sugar alcohol solution to produce C5, C6 alkanes, characterized in that it comprises the following steps:

[0032] (1) Preparation of Ru / C catalyst: Weigh 5g of activated carbon (70-120 mesh) into a round bottom flask, then slowly add 100mL of deionized water and a stirring magnet, then condense the reflux device on the round bottom flask, put the whole Heat in an oil bath and maintain magnetic stirring at 450 rpm, and treat at a constant temperature of 90°C in an oil bath for 5 hours. Then cool to normal temperature, filter and wash, the filter cake is washed 3 times with deionized water, and then put into a drying oven at 120° C. to dry overnight to obtain an activated activated carbon carrier. Then take 4mL (2g) to handle the activated carbon carrier particles (Tangshan Huaneng Technology Carbon Industry Co., Ltd., model HN-Y14, 70-120 mesh), impregnate ruthenium trichloride (Ru content 37%, RuCl 3 .xH 2 (0:0.22g) soluti...

Embodiment 2

[0040] A method for converting an acidic biomass-based sugar alcohol solution to produce C5, C6 alkanes, is characterized in that it comprises the following steps:

[0041](1) Preparation of Ru / C catalyst: Weigh 5g of activated carbon (70-120 mesh) into a round bottom flask, then slowly add 100mL of deionized water and a stirring magnet, then condense the reflux device on the round bottom flask, put the whole Heat in an oil bath and maintain magnetic stirring at 450 rpm, and treat at a constant temperature of 90°C in an oil bath for 5 hours. Then cool to normal temperature, filter and wash, the filter cake is washed 3 times with deionized water, and then put into a drying oven at 120° C. to dry overnight to obtain an activated activated carbon carrier. Then take 4mL (2g) to handle the activated carbon carrier particles (Tangshan Huaneng Technology Carbon Industry Co., Ltd., model HN-Y14, 70-120 mesh), impregnate ruthenium trichloride (Ru content 37%, RuCl 3 .xH 2 (0:0.22g) s...

Embodiment 3

[0049] A method for converting an acidic biomass-based sugar alcohol solution to produce C5, C6 alkanes, is characterized in that it comprises the following steps:

[0050] (1) Preparation of Ru / C catalyst: Weigh 5g of activated carbon (70-120 mesh) into a round bottom flask, then slowly add 100mL of deionized water and a stirring magnet, then condense the reflux device on the round bottom flask, put the whole Heat in an oil bath and maintain magnetic stirring at 450 rpm, and treat at a constant temperature of 90°C in an oil bath for 5 hours. Then cool to normal temperature, filter and wash, the filter cake is washed 3 times with deionized water, and then put into a drying oven at 120° C. to dry overnight to obtain an activated activated carbon carrier. Then take 4mL (2g) to handle the activated carbon carrier particles (Tangshan Huaneng Technology Carbon Industry Co., Ltd., model HN-Y14, 70-120 mesh), impregnate ruthenium trichloride (Ru content 37%, RuCl 3 .xH 2 (0:0.22g) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com