Garnet ferrite material applied to high-power phase shifter and preparing method thereof

A technology of ferrite material and phase shifter, which is applied in the field of garnet ferrite material and its preparation, can solve the problems of increased insertion loss and large loss of phase shifter, and reduce the operating distance of phased array radar, etc., to achieve The effect of small effective line width, small porosity and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

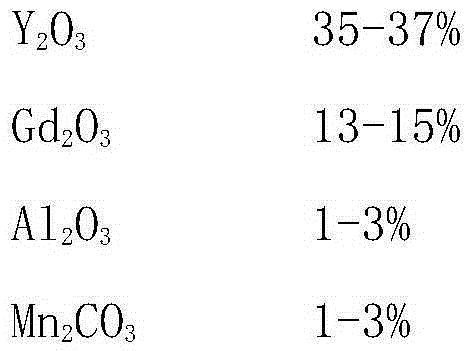

[0034] A garnet ferrite material applied to a high-power phase shifter, the ferrite material is made of ingredients in the following weight ratios:

[0035]

Embodiment 2

[0037] A method for preparing a garnet ferrite material applied to a high-power phase shifter,

[0038] 1) Weigh the ingredients according to the following weight:

[0039]

[0040] The total weight is 3019 grams.

[0041] 2) One-time ball milling: add 3019 grams of ingredients weighed in step 1) into 1800ml of distilled water and 1800ml of alcohol and put them into a ball mill for 24 hours, at a speed of 75 rpm to mix the ingredients evenly, material (g): distilled water (m1): The ratio of alcohol (m1):ball (g) is 1:0.6:0.6:2.

[0042] 3) drying: drying the ball-milled ingredients in step 2) at 95°C.

[0043] 4) Sieving: Pass the dried powder in step 3) through a 30-mesh sieve.

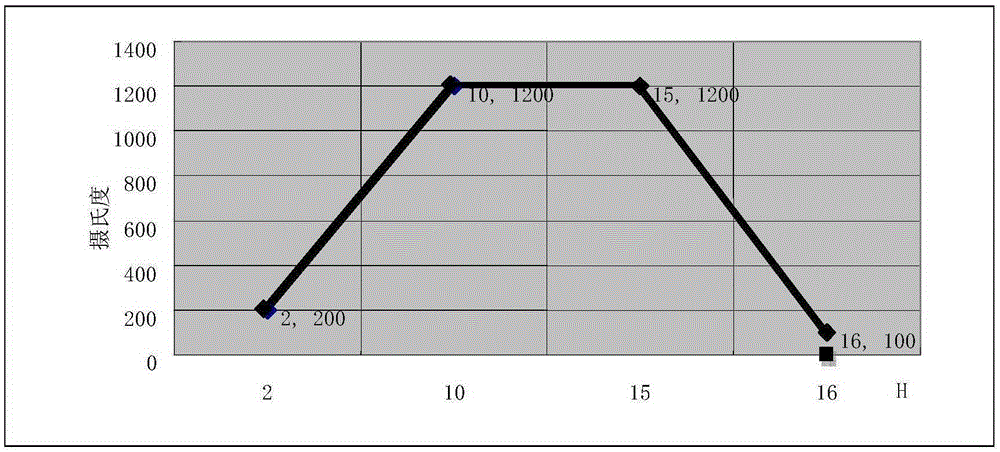

[0044] 5) Pre-burning: the powder obtained in step 4) is pressed figure 1 According to the pre-burning curve, heat up and keep warm, uniformly heat up from room temperature to 200°C within 2 hours, from 200°C to 1200°C within 8 hours, keep at 1200°C for 5 hours, and then cool naturally with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com