Inorganic fiber heat-insulation layer protection surface layer and spraying method thereof

A technology of inorganic fiber and protective surface, applied in the field of inorganic fiber thermal insulation layer protective surface layer and its spraying, can solve the problems of lack of aesthetics, reduced bonding strength of the base layer, hidden dangers and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

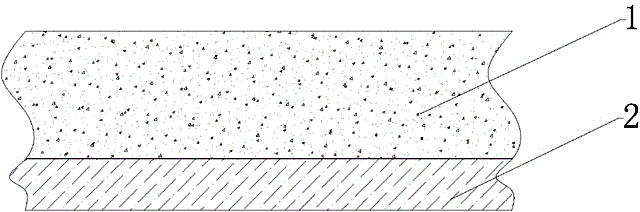

[0032] Such as figure 1 As shown, in this embodiment, a thermal insulation layer protective surface layer 2 made of inorganic fibers is directly sprayed and attached to the thermal insulation layer 1. The protective surface layer is formed by spraying inorganic fiber coatings, and the basic composition of the inorganic fiber coatings is as follows: Down:

[0033] White cement: 250-350 weight units;

[0034] Heavy calcium carbonate: 500-600 weight units;

[0035] Ash calcium: 100 weight units;

[0036] Vegetable protein fiber: 5 weight units;

[0037] Polyvinyl alcohol PVA: 2 weight units;

[0038] Modified polyethylene oxide: 4-5 weight units;

[0039] Modified seaweed: 4-6 weight units;

[0040] Polymer rubber powder: 40-50 weight units;

[0041] Thickening water-retaining agent: 4 weight units;

[0042] Hydrophobic agent: 0.5-1 weight unit;

[0043] Water: 700-800 weight units.

[0044] Among them, the polymer rubber powder is ethylene-vinyl acetate redispersible l...

Embodiment 2

[0047] A spraying method for spraying the thermal insulation layer protective surface layer made of the inorganic fiber, the specific steps are as follows:

[0048] 1) Manufacture the inorganic fiber coating on site, and mix it into a slurry with a set consistency after sufficient stirring;

[0049] 2) Treat the insulation layer, flatten or remove the protrusions on the surface of the insulation layer, fill in the holes, and ensure the flatness of the entire insulation layer surface;

[0050] 3) Use spraying equipment to carry out spraying operation, so that the slurry is attached to the surface of the thermal insulation layer; the spraying thickness is about 1.5-3mm.

[0051] 4) Check the sprayed surface, and re-spray until the surface is complete and survive the area that is not completely covered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com