Non-shrinkage high-sound-isolation self-heat-insulation heat-isolation sand light wall module and manufacturing method thereof

A technology for a lightweight wall and a manufacturing method, which is applied in the field of wall materials, can solve the problems of high production energy consumption, affect structural safety, and be difficult to achieve, and achieve the effects of strong absorption capacity, low thermal conductivity, and attenuation of sound waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

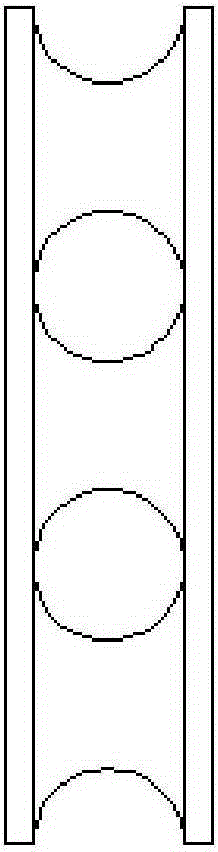

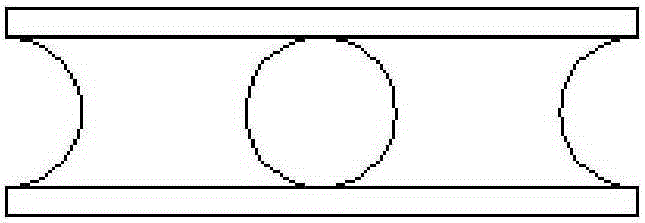

[0059] Specific implementation mode 1: The non-shrinkage, high sound insulation, self-insulation and thermal insulation mud-sand lightweight wall module of this implementation mode is non-self-supporting, and the structure is as follows Figure 1-3 Shown, per cubic meter is made of the following raw materials:

[0060] 15Kg of ultra-light aggregate, 155Kg of cement, 10Kg of silt, 0.15Kg of bulk mud shrinkage inhibitor, 0.5Kg of interfacial activity enhancer, 3Kg of melt viscosity hollow particle polymer and 65Kg of water; count) of flying sand.

[0061] The ultra-light aggregate is polystyrene particles.

[0062] The bulk mud shrinkage inhibitor is composed of 35% alkylphenol polyoxyethylene ether, 57.5% 2-methyl-2,4-pentanediol and 7.5% sodium α-alkenyl sulfonate in mass percentage.

[0063] The surface activity enhancing agent is composed of 85% polymer emulsion, 2.5% curing agent and 12.5% dispersing agent according to mass percentage.

[0064] The polymer emulsion is ...

specific Embodiment approach 2

[0077] Embodiment 2: The non-shrinkage, high-sound-insulation, self-insulation and heat-insulation mud-sand lightweight wall module of this embodiment is non-self-supporting, and is made of the following raw materials per cubic meter:

[0078] 75Kg of ultra-light aggregate, 195Kg of cement, 25Kg of silt, 0.20Kg of bulk mud shrinkage inhibitor, 0.75Kg of surface activity enhancer, 5Kg of melt viscosity hollow particle polymer and 85Kg of water; count) natural sand.

[0079] The ultra-light aggregate is expanded vitrified microspheres.

[0080] The bulk mud shrinkage inhibitor is composed of 40% alkylphenol polyoxyethylene ether, 55% 2-methyl-2,4-pentanediol and 5% sodium α-olefin sulfonate according to the mass percentage.

[0081] The surface activity enhancer is composed of 90% polymer emulsion, 2.5% curing agent and 7.5% dispersant according to mass percentage.

[0082] The polymer emulsion is styrene-acrylic emulsion, the curing agent is lithium silicate sol, and the disp...

specific Embodiment approach 3

[0089] Embodiment 3: The non-shrinkage, high-sound insulation, self-insulation and heat-insulation silt lightweight wall module of this embodiment is non-self-supporting, and is made of the following raw materials per cubic meter:

[0090] 45Kg of ultra-light aggregate, 175Kg of cement, 15Kg of silt, 0.25Kg of bulk mud shrinkage inhibitor, 0.625Kg of surface active enhancer, 4.0Kg of melt viscosity hollow particle polymer and 75Kg of water; mass meter) of sea sand.

[0091] The ultra-light aggregate is 10Kg of polystyrene particles and 35Kg of expanded vitrified microbeads.

[0092] The bulk mud shrinkage inhibitor is composed of 35% of alkylphenol polyoxyethylene ether, 55% of 2-methyl-2,4-pentanediol and 10% of sodium α-alkenyl sulfonate.

[0093] The surface activity enhancer is composed of 85% polymer emulsion, 7.5% curing agent and 7.5% dispersant according to mass percentage.

[0094] The polymer emulsion is ethylene-vinyl acetate, the curing agent is sodium silicate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com