Polycarboxylate superplasticizer with super high early strength and preparation method of polycarboxylate superplasticizer

A technology of early-strength polycarboxylate and strong polycarboxylate, which is applied in the field of ultra-early-strength polycarboxylate water reducer and its preparation, can solve the problems of unsatisfactory concrete construction performance, poor mud resistance, and large loss of concrete slump. problems, to achieve the effect of accelerating water reconciliation, increasing water reduction rate, and reducing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

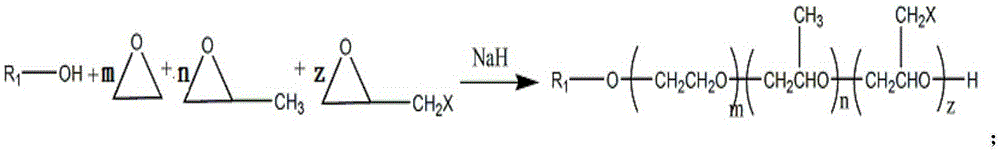

[0049] A kind of embodiment of the preparation method of active macromonomer described in the present invention:

[0050] 1), the synthesis of active intermediates

[0051] Inject 5 mol of prenyl alcohol, 5 g of sodium hydride, 25 mol of ethylene oxide, and 5 mol of epichlorohydrin into a closed autoclave, stir, and react at 80° C. for 10 h to obtain the active intermediate of the reaction product.

[0052] 2) Synthesis of active macromers

[0053] Add 1 mol of triethylamine and 0.001 mol of hydroquinone into the flask, raise the temperature to 10°C, slowly add dropwise the triethylamine solution containing 5 mol of the active intermediate synthesized in step (1), after the dropwise addition, at 10°C Next, continue the incubation reaction for 10h to obtain the active macromonomer.

Embodiment 2

[0055] A kind of embodiment of the preparation method of cationic quaternary ammonium salt PEO active macromer of the present invention:

[0056] 1), the synthesis of active intermediates

[0057] Inject 5 mol of isobutenyl alcohol, 20 g of sodium hydride, 500 mol of ethylene oxide, 250 mol of propylene oxide, and 750 mol of epibromohydrin into a closed autoclave, stir, and react at 150°C for 2 hours to obtain the active intermediate of the reaction product.

[0058] 2) Synthesis of active macromers

[0059] Add 3 mol of trimethylamine and 0.004 mol of hydroquinone into the flask, raise the temperature to 30°C, slowly add dropwise the trimethylamine solution containing 5 mol of the active intermediate synthesized in step (1), after the dropwise addition, at 30°C, Continue the insulation reaction for 10h to obtain the active macromonomer.

Embodiment 3

[0061] A kind of embodiment of the preparation method of active macromonomer described in the present invention:

[0062] 1), the synthesis of active intermediates

[0063] Inject 5 mol allyl alcohol, 10 g sodium hydride, 1000 mol ethylene oxide, and 400 mol epoxy iodopropane into a closed autoclave, stir, and react at 100°C for 6 hours to obtain the active intermediate of the reaction product.

[0064] 2) Synthesis of active macromers

[0065] Add 5 mol of tripropylamine and 0.0015 mol of hydroquinone into the flask, heat up to 50°C, slowly add dropwise the tripropylamine solution containing 5mol of the active intermediate synthesized in step (1), after the dropwise addition, at 50°C, Continue the heat preservation reaction for 8h to obtain the active macromonomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com