Anti-skid treatment process of floor tiles

A technology for anti-skid treatment and floor tiles, which is applied in the field of building ceramics, can solve the problems of small friction coefficient and the surface of floor tiles is easy to be slippery, etc., and achieves the effect of easy cleaning and solving wet and slippery in contact with water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

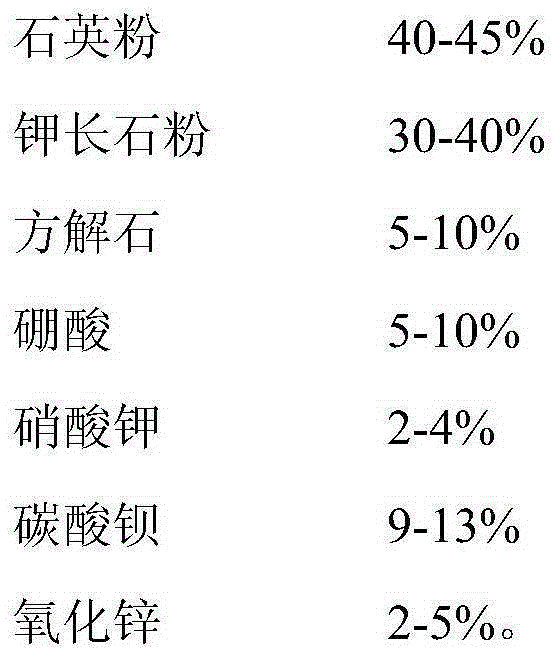

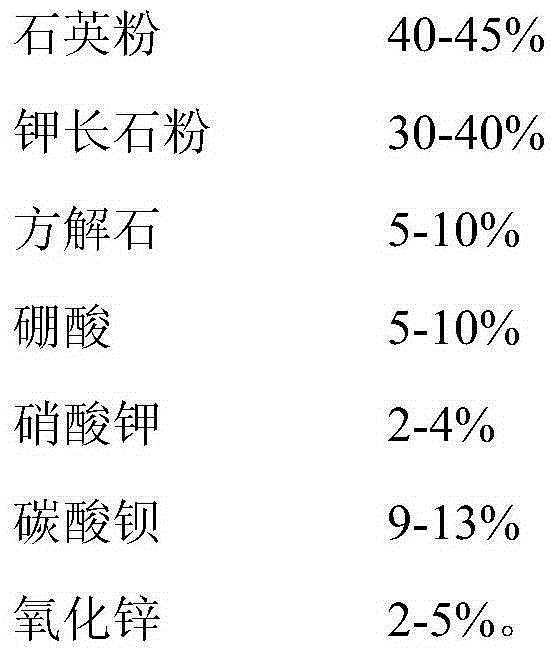

[0025] Dry glaze formula: 40% quartz powder, 36% potassium feldspar powder, 5% calcite, 5% boric acid, 2% potassium nitrate, 10% barium carbonate, 2% zinc oxide. After the dry glaze of this formula is processed into granules, the percentage of sieves larger than 20 mesh is 3%, 20-40 mesh is 42%, 40-60 mesh is 42%, and 60 mesh is sieved. The above accounted for 13%.

[0026] Add the processed dry glaze to the surface glaze according to the proportion of 20% of the surface glaze, stir evenly, and then apply glaze on the floor tiles of 30cm*30cm according to the glaze amount of 55 grams per tile, the firing temperature is 1150 ° C, and the firing cycle is 40 Minutes, the anti-slip particles on the surface of the fired product are clearly visible, and the hand feel is obvious. After the dirt absorption test, it does not absorb dirt at all, and other physical and chemical indicators fully meet the national standards.

Embodiment 2

[0028] Dry glaze formula: 44% quartz powder, 30% potassium feldspar powder, 5% calcite, 5% boric acid, 2% potassium nitrate, 10% barium carbonate, 4% zinc oxide. After the dry glaze of this formula is processed into granules, the percentage of sieves larger than 20 mesh is 4.5%, 20-40 mesh is 44%, 40-60 mesh is 41%, and 60 mesh is 4.5%. Above the sieve accounted for 10.5%.

[0029] Add the processed dry glaze to the surface glaze according to the proportion of 28% of the surface glaze, stir evenly, and then apply glaze on the floor tiles of 30cm*30cm according to the glaze amount of 48 grams per tile, the firing temperature is 1180 ° C, and the firing cycle is 45 Minutes, the anti-slip particles on the surface of the fired product are dense, clearly visible, and the handle feels obvious. After the dirt absorption test, it does not absorb dirt at all, and other physical and chemical indicators fully meet the national standards.

Embodiment 3

[0031] Dry glaze formula: quartz powder 41%, potassium feldspar powder 36%, calcite 5%, boric acid 5%, potassium nitrate 2%, barium carbonate 9%, zinc oxide 2%. After the dry glaze of this formula is processed into granules, the percentage of sieves larger than 20 mesh is 2%, 20-40 mesh is 35%, 40-60 mesh is 50%, and 60 mesh is sieved. Above the sieve accounted for 13%.

[0032] Add the processed dry glaze to the surface glaze according to the proportion of 12% of the surface glaze, stir evenly, and then apply glaze on the floor tiles of 30cm*30cm according to the glaze amount of 68 grams per tile, the firing temperature is 1120°C, and the firing cycle is 35 Minutes, the non-slip particles on the surface of the fired product are relatively dispersed, the particles are clear and obvious, and the handle has a good protruding effect. After the dirt absorption test, it does not absorb dirt at all, and other physical and chemical indicators fully meet the national standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com