Method for preparing high-purity barium salt by using witherite-barytocalcite industrial waste residues

A technology for industrial waste residue and barium calcite, which is applied in the removal of solid waste, calcium/strontium/barium halide, calcium/strontium/barium chloride, etc. Low, no practicability and other problems, to achieve significant economic and environmental benefits, less emissions of three wastes, and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

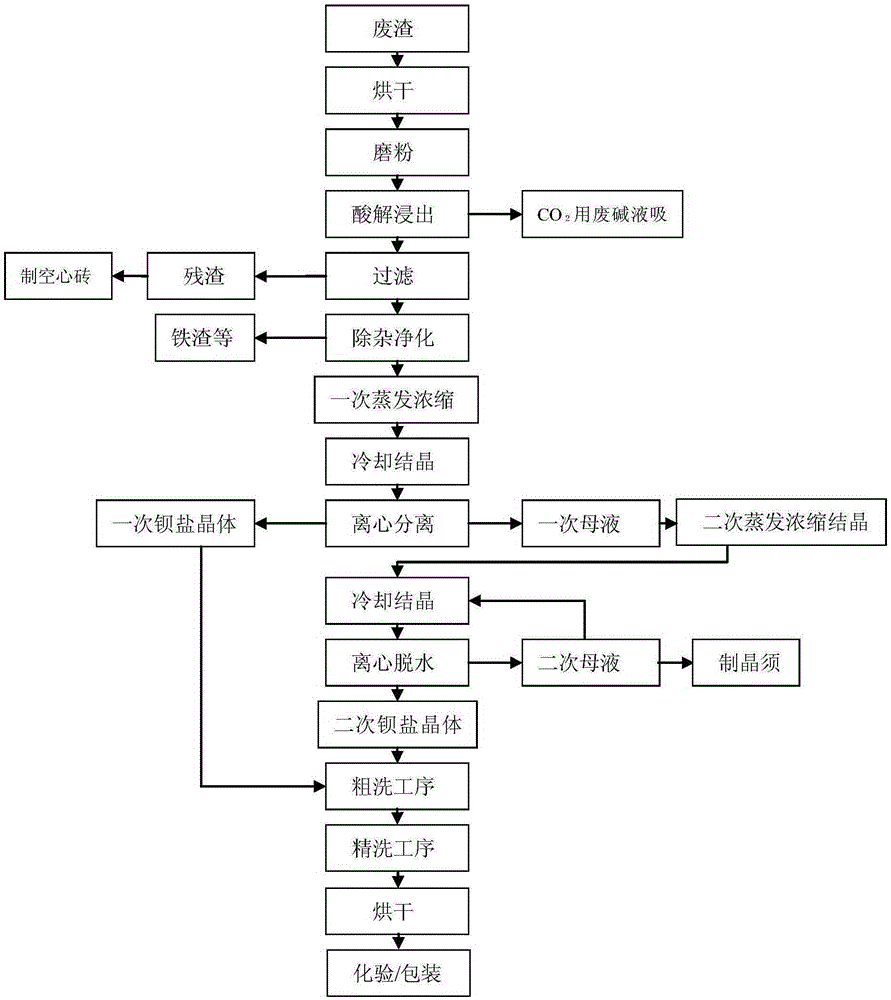

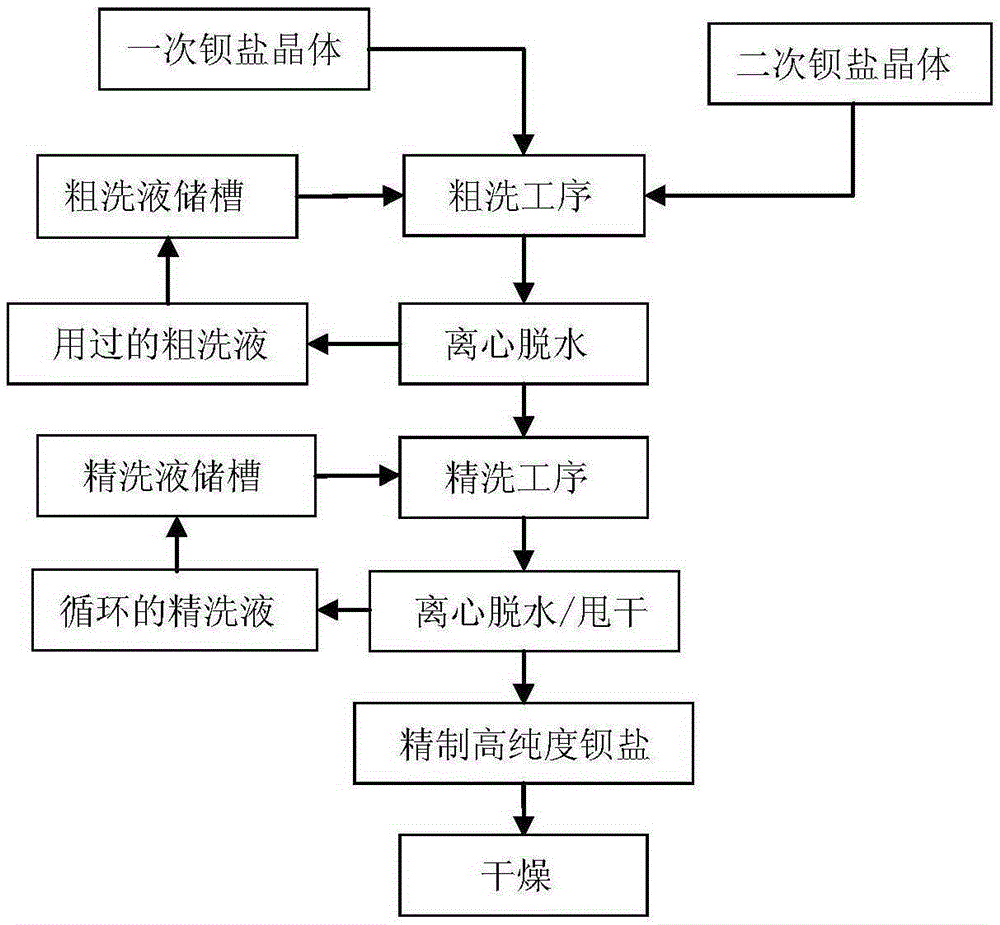

Method used

Image

Examples

Embodiment 1

[0037] Firstly, dry the witherite-bariumite industrial waste residue with a grade of 60% (degrees) until the water content is below 0.5%, then crush and grind the waste residue, and obtain -100 mesh slag powder after sieving; In an enamel reaction kettle with a stirrer and induced draft fan, add 300 kg of tap water, start the mixer, and slowly add 1 ton of -100 mesh slag powder to mix. Turn on the induced draft fan, add hydrochloric acid with a concentration of 30% according to the liquid-solid ratio of 1.0, and stir at a temperature of 40°C for 5 minutes to carry out acidolysis. And control the pH of the leaching end point in the range of 2.5-4.0; filter and separate the residue, add 10 kg of hydrogen peroxide to the obtained filtrate, wherein the mass fraction of hydrogen peroxide is 27.5%, stir for 10 minutes, and then slowly add a pH regulator until the pH value Adjust to 8.0, heat up to 70-80°C, add 4 kg of activated carbon, and boil for 7 minutes; then filter, and the re...

Embodiment 2

[0039] Firstly, dry the witherite-bariumite industrial waste residue with a grade of 60% (degrees) until the water content is below 0.5%, then crush and grind the waste residue, and obtain -100 mesh slag powder after sieving; In an enamel reaction kettle with a stirrer and induced draft fan, add 300 kg of tap water, start the mixer, and slowly add 1 ton of -100 mesh slag powder to mix. Turn on the induced draft fan, add hydrochloric acid with a concentration of 30% according to the liquid-solid ratio of 1.2, and stir at a temperature of 40°C for 5 minutes to carry out acidolysis. And control the pH of the leaching end point in the range of 2.5-4.0; filter and separate the residue, add 10 kg of hydrogen peroxide to the obtained filtrate, wherein the mass fraction of hydrogen peroxide is 27.5%, stir for 10 minutes, and then slowly add a pH regulator until the pH value Adjust to 8.0, heat up to 70-80°C, add 3 kg of activated carbon, and boil for 7 minutes; then filter, and the re...

Embodiment 3

[0041]Firstly, dry the witherite-bariumite industrial waste residue with a grade of 60% (degrees) until the water content is below 0.5%, then crush and grind the waste residue, and obtain -100 mesh slag powder after sieving; In an enamel reaction kettle with a stirrer and induced draft fan, add 300 kg of tap water, start the mixer, and slowly add 1 ton of -100 mesh slag powder to mix. Turn on the induced draft fan, add hydrochloric acid with a concentration of 25% according to the liquid-solid ratio of 1.2, and stir at a temperature of 30°C for 10 minutes to carry out acidolysis. And control the pH of the leaching end point in the range of 2.5-4.0; filter and separate the residue, add 30 kg of hydrogen peroxide to the obtained filtrate, wherein the mass fraction of hydrogen peroxide is 27.5%, stir for 8 minutes, and then slowly add a pH regulator until the pH value Adjust to 8.0, heat up to 70 ° C, add 3.5 kilograms of gac, and boil to a slight boil for 4 minutes; filter again...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com