Preparation method for NiFe2O4@alpha-Fe micro nanometer composite material of core-shell structure

A composite material and core-shell structure technology, applied in the direction of nanotechnology, can solve the problems of easy oxidation, narrow absorption frequency band, poor matching performance, etc., and achieve the effects of easy acquisition, low preparation cost, and improved microwave absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Add 10g of purchased NiFe 2 o 4 powder and 15ml iron pentacarbonyl [Fe(CO) 5 ] into the reactor and the evaporator respectively;

[0033] Step 2: Switch on N 2 , blow out all the air in the pipeline, turn off the gas source, and close the valve between the reactor and the evaporator at the same time; 2 o 4 and Fe(CO) 5 Open the valve between the reactor and the evaporator when heating to 210°C and 80°C;

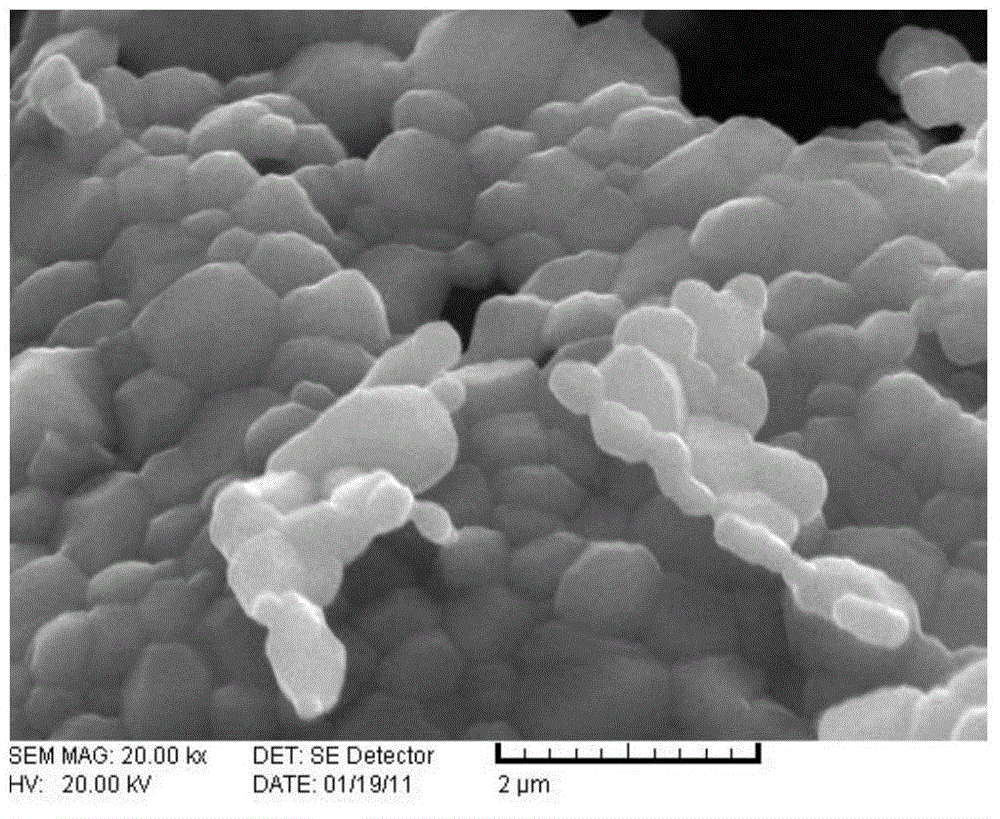

[0034] Step 3: Fe(CO) 5 Steam was blown into the reactor, and the stirring speed was 200r / min. N 2 The flow rate is controlled by a gas flow meter; Fe(CO) 5 Heated by a digital display constant temperature oil bath, gaseous Fe(CO) 5 The pipeline before entering the reactor is covered with a layer of insulation jacket to prevent the gaseous Fe(CO) 5 Condensation at low temperature, resulting in poor pipeline; Fe(CO) 5 The steam blowing time is 30min, and the final sample is in N 2 Cool and collect under protection, the obtained black powder is NiFe ...

Embodiment 2

[0040] Step 1: 10g of prepared NiFe 2 o 4 powder and 15ml iron pentacarbonyl [Fe(CO) 5 ] into the reactor and the evaporator respectively;

[0041] Step 2: Switch on N 2 , Blow out all the air in the pipeline, turn off the air source, and close the valve between the reactor and the evaporator at the same time. NiFe 2 o 4 and Fe(CO) 5 Open the valve between the reactor and the evaporator when heating to 250°C and 80°C;

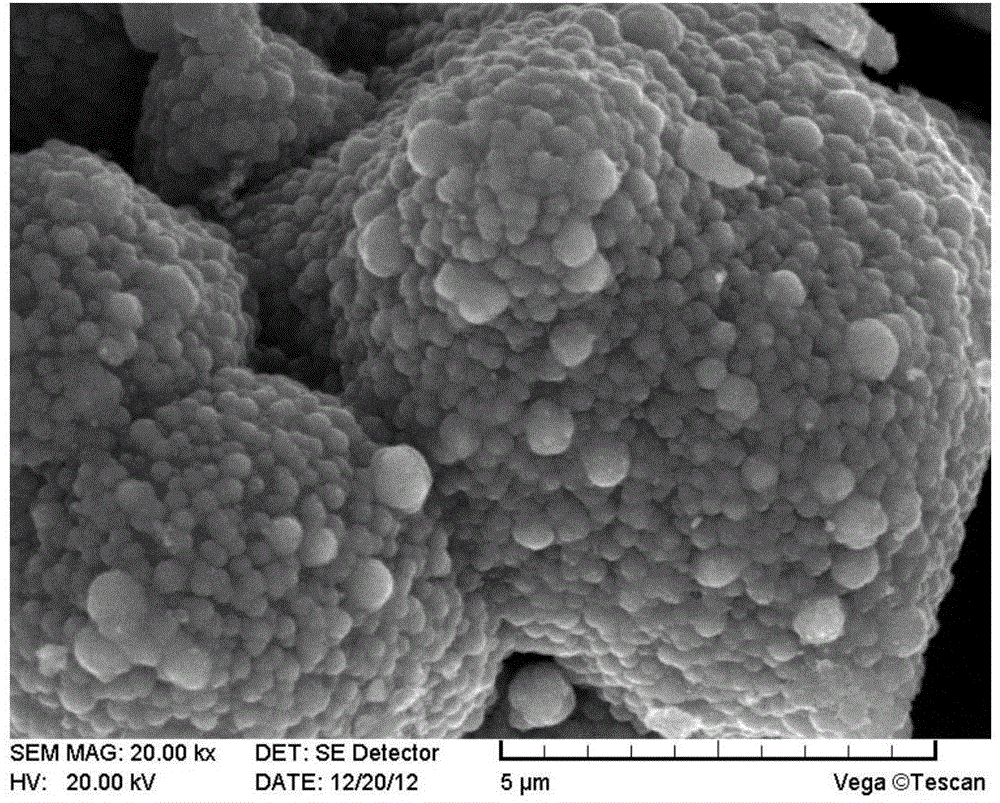

[0042] Step 3: Fe(CO) 5 The steam is blown into the reactor, and the stirring speed is 180r / min; N 2 The flow rate is controlled by a gas flow meter; Fe(CO) 5 Heated by a digital display constant temperature oil bath, gaseous Fe(CO) 5 The pipeline before entering the reactor is covered with a layer of insulation jacket to prevent the gaseous Fe(CO) 5 Condensation at low temperature, causing pipeline blockage. Fe(CO) 5 The steam blowing time is 30min, and the final sample is in N 2 Cool and collect under protection, the obtained black powder is NiF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com