Control method for mixed casting of continuous-cast tundish

A control method and continuous casting technology are applied in the field of metallurgy to achieve the effects of improving control precision, accurate and reliable control, and improving the yield of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

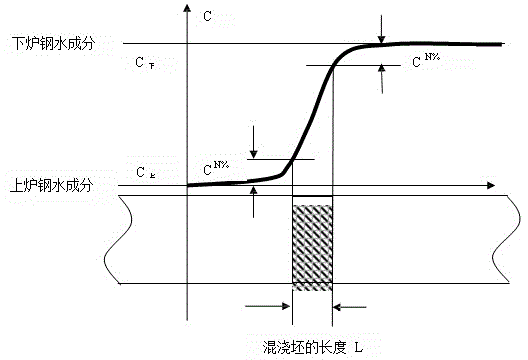

[0032] In the continuous casting process, when the nozzle of the next large ladle is opened, a certain amount of molten steel must be left in the tundish to maintain the continuity of casting and prevent the scum on the liquid steel surface from being involved in the mold. When the tundish receives the next batch of molten steel, it is mixed with the molten steel originally left in the tundish, and flows into the crystallizer to form a mixed billet. If the chemical composition of the two heats of molten steel is different, the chemical composition of the molten steel in the tundish will gradually transition. The longer the transition time, the more concrete will be formed. Theoretically, the transition time of the chemical composition of molten steel needs to be infinitely long. In actual production, as long as the chemical composition of molten steel in the tundish is within the normal fluctuation range, the transition can be considered complete. The changes in the composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com