Preparation of oil-water separation mesh membrane and surface wettability conversion method thereof

An oil-water separation mesh membrane and surface infiltration technology, which is applied in separation methods, liquid separation, semi-permeable membrane separation, etc. Good chemical stability and mechanical stability, low cost, good separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of preparation method of oil-water separation omentum, comprises the following steps:

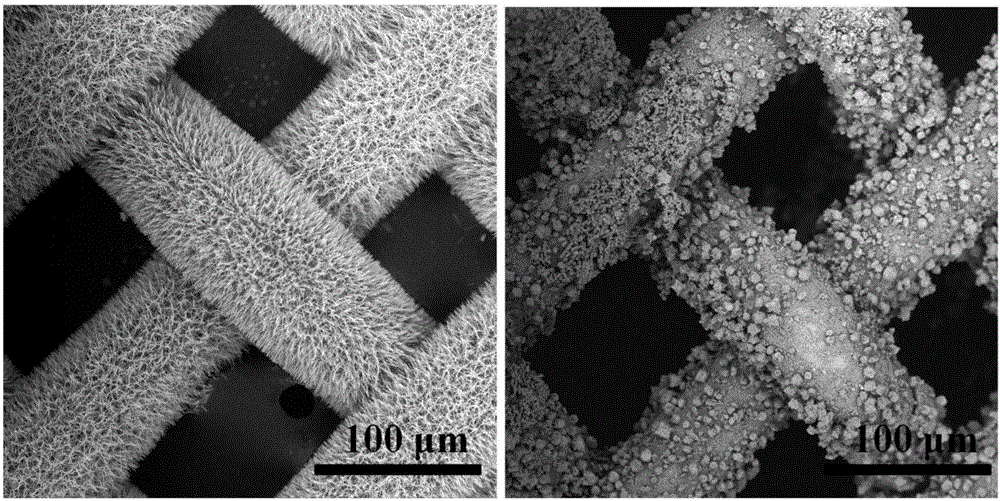

[0051] A. In the alkaline medium of sodium hydroxide solution with a concentration of 0.5mol / L, potassium disulfate with a concentration of 0.01mol / L is used to oxidize 150-mesh copper to build a micro-nano structure on its surface to obtain needles with a micro-nano level. Shaped or spherical convex omentum, prepared omentum structure with micro-nano needle or spherical protrusions such as figure 1 shown;

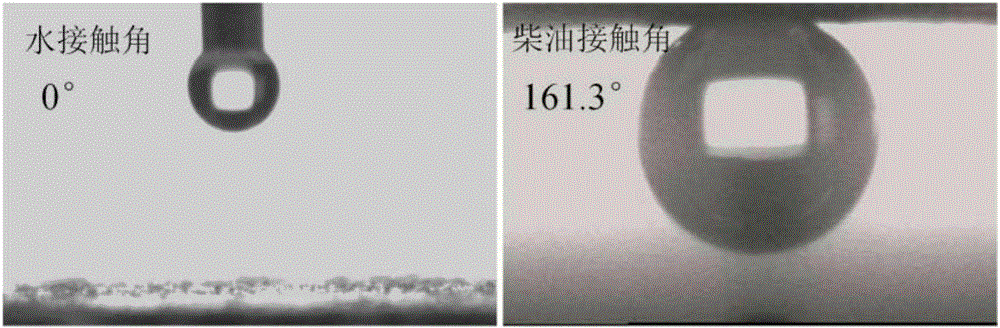

[0052] B, thermal oxidation treatment to prepare super-hydrophilic and oleophobic omentum: the copper mesh with micro-nano structure on the surface prepared in step A is placed in an electric furnace, thermal oxidation treatment in air atmosphere, the time of thermal oxidation treatment is 3min, heat The temperature of the oxidation treatment is 300°C; the omentum after heat treatment is taken out to obtain a superhydrophilic and oleophobic omentum, and the experimental r...

Embodiment 2

[0058] A kind of preparation method of oil-water separation omentum, comprises the following steps:

[0059] A, in the alkaline medium that concentration is the potassium hydroxide solution of 7.5mol / L, by the sodium disulfate solution oxidizing 200 mesh coppers that concentration is 0.5mol / L build micro-nano structure on its surface;

[0060] B, thermal oxidation treatment to prepare super-hydrophilic and oleophobic omentum: the copper mesh with micro-nano structure on the surface prepared in step A is placed in an electric furnace, thermal oxidation treatment in air atmosphere, the time of thermal oxidation treatment is 3min, heat The temperature of the oxidation treatment is 300°C; the omentum after heat treatment is taken out to obtain a superhydrophilic and oleophobic omentum;

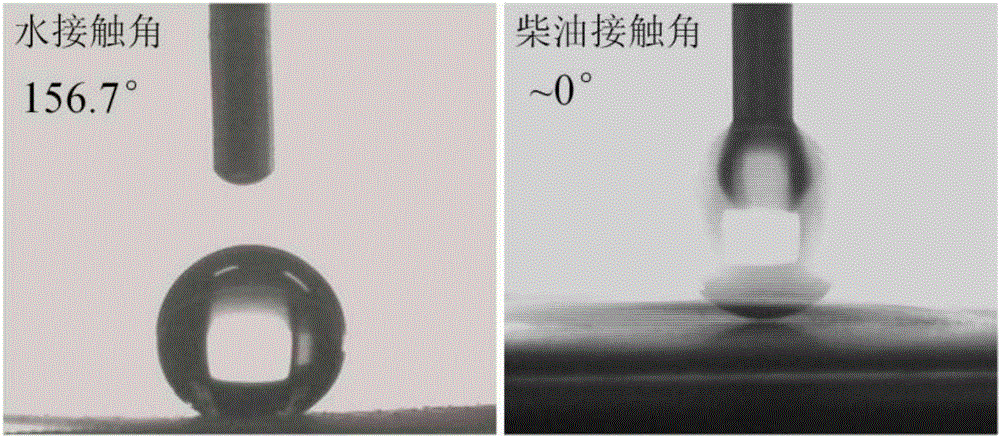

[0061] C, wet chemical method processing prepares superhydrophobic oleophilic omentum: the superhydrophilic oleophobic omentum prepared by step B is immersed in the tetradecanoic acid (myristic ac...

Embodiment 3

[0067] A kind of preparation method of oil-water separation omentum, comprises the following steps:

[0068] A, in the alkaline medium of the sodium hydroxide solution that concentration is 3mol / L, by the ammonium disulfate solution oxidation 400 mesh stainless steel nets that concentration is 0.3mol / L build micro-nano structure on its surface;

[0069] B, thermal oxidation treatment to prepare super-hydrophilic and oleophobic omentum: the surface prepared in step A is placed in an electric furnace with a stainless steel mesh of micro-nano structure, and thermal oxidation treatment is performed in an air atmosphere. The time of thermal oxidation treatment is 20min, heat The temperature of the oxidation treatment is 180°C; the omentum after heat treatment is taken out to obtain a superhydrophilic and oleophobic omentum;

[0070] C, wet chemical method processing to prepare superhydrophobic oleophilic omentum: the superhydrophilic oleophobic omentum that step B is prepared is im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com