One-bath process dyeing auxiliaries and application method thereof on polyester taffeta fabric

A technology of dyeing auxiliaries and application methods, which is applied in the direction of dyeing, textile material processing, and continuous processing of textile materials, etc., and can solve problems such as high energy consumption, high operation requirements, and uneven tension of the cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

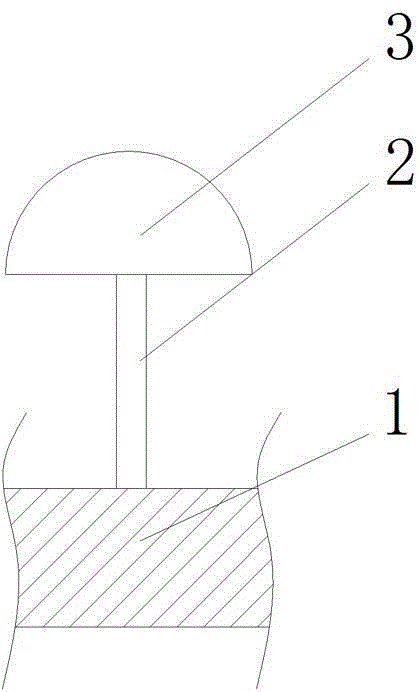

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of one-bath dyeing auxiliaries of this example, the composition and mass percent of auxiliaries are: sodium carbonate 40%, sodium silicate 14%, sodium dodecylbenzenesulfonate 13%, dodecane Sodium sulfate 5%, fatty acid methyl ester sulfonate 4%, fatty alcohol polyoxyethylene ether 6%, fatty alcohol polyoxyethylene ether sodium sulfate 9%, sodium tripolyphosphate 9%.

[0024] The application method of one-bath dyeing auxiliaries on polyester taffeta fabrics, the steps are:

[0025] a. Sodium carbonate, sodium silicate, sodium dodecylbenzene sulfonate, sodium lauryl sulfate, fatty acid methyl ester sulfonate, fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether sodium sulfate, tripolyphosphoric acid The sodium is compounded and stirred according to the above ratio to form a mixture evenly, and then the mixture is put into water, the mixture accounts for 1% of the total mass, and the pH value is adjusted to 9 to form a one-bath dye...

Embodiment 2

[0029] Embodiment 2: a kind of one-bath method dyeing auxiliaries of this example, the composition and mass percent of auxiliaries are: sodium carbonate 35%, sodium silicate 16%, sodium dodecylbenzene sulfonate 15%, dodecane Sodium sulfate 8%, fatty acid methyl ester sulfonate 3%, fatty alcohol polyoxyethylene ether 9%, fatty alcohol polyoxyethylene ether sodium sulfate 7%, sodium tripolyphosphate 7%.

[0030] The application method of one-bath dyeing auxiliaries on polyester taffeta fabrics, the steps are:

[0031] a. Sodium carbonate, sodium silicate, sodium dodecylbenzene sulfonate, sodium lauryl sulfate, fatty acid methyl ester sulfonate, fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether sodium sulfate, tripolyphosphoric acid The sodium is compounded and stirred according to the above ratio to form a mixture evenly, and then the mixture is put into water, the mixture accounts for 1% of the total mass, and the pH value is adjusted to 9 to form a one-...

Embodiment 3

[0035] Embodiment 3: a kind of one-bath method dyeing auxiliaries of this example, the composition and mass percent of auxiliaries are: sodium carbonate 45%, sodium silicate 12%, sodium dodecylbenzene sulfonate 10%, dodecane Sodium sulfate 4%, fatty acid methyl ester sulfonate 6%, fatty alcohol polyoxyethylene ether 9%, fatty alcohol polyoxyethylene ether sodium sulfate 7%, sodium tripolyphosphate 7%.

[0036] The application method of one-bath dyeing auxiliaries on polyester taffeta fabrics, the steps are:

[0037] a. Sodium carbonate, sodium silicate, sodium dodecylbenzene sulfonate, sodium lauryl sulfate, fatty acid methyl ester sulfonate, fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether sodium sulfate, tripolyphosphoric acid The sodium is compounded and stirred according to the above ratio to form a mixture evenly, and then the mixture is put into water, the mixture accounts for 1% of the total mass, and the pH value is adjusted to 9 to form a one-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com