Polyester taffeta rip-stop fabric and production method for same

A production method and polyester technology, which are applied to polyester lattice fabrics and the production field thereof, can solve the problems of coexistence of uneven fabric effects and lattice effects, etc., and achieve the effects of light and thin texture, lasting uneven effect and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

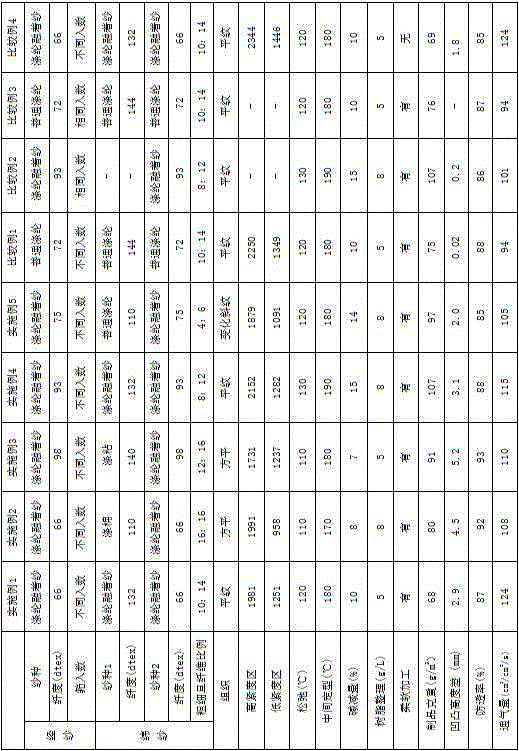

Embodiment 1

[0044] The warp yarn is 66dtex-72f-polyester fused with DTY, and reeds are inserted according to different reed numbers. The weft yarn is 132dtex-144f-polyester fused with DTY and 66dtex-72f-polyester fused with DTY, and the reeds are inserted alternately according to the cycle of 10:14. The organization adopts plain weave, and the gray cloth is made on a single-axis water-jet loom.

[0045] The gray cloth goes through scouring→relaxation→intermediate shaping→continuous reduction→dyeing→resin processing→finishing and shaping→mechanical soft processing. The final grammage is 68g / m 2 finished product.

[0046] Among them, relaxation processing conditions: temperature 120°C, heat preservation 20min. Intermediate shaping processing conditions: temperature 180°C, operating speed 60m / min, fan power 30Hz. Continuous reduction conditions: reduction rate of 10%. Dyeing conditions: 130℃*20min for disperse dyeing. Resin processing conditions: temperature 150°C, resin finishing SUNSO...

Embodiment 2

[0049]The warp yarn is 66dtex-72f-polyester fused with DTY, and the reed is inserted according to the number of reeds. The weft yarn is 45 polyester-cotton blended yarns (65:35) and 66dtex-72f-polyester fused with DTY, according to the cycle of 16:16 Alternate punching, the weave adopts square flat, and the gray cloth is made on a single-axis air-jet loom.

[0050] The gray cloth goes through scouring→relaxation→intermediate shaping→continuous reduction→dyeing→resin processing→finishing and shaping→mechanical soft processing. The final grammage is 80g / m 2 finished product.

[0051] Among them, relaxation processing conditions: temperature 110°C, heat preservation 20min. Intermediate shaping processing conditions: temperature 170°C, operating speed 50m / min, fan power 30Hz. Continuous reduction conditions: reduction rate of 8%. Dyeing conditions: 130℃*20min for disperse dyeing. Resin processing conditions: temperature 150°C, resin finishing SUNSOFTERA-700: 8g / L. Mechanical...

Embodiment 3

[0054] The warp yarn is 98dtex-36f-polyester fused with DTY, and the reed is inserted according to the number of reeds, and the weft yarn is 40 polyester-viscose blended yarns (65:35) and 98dtex-36f-polyester fused with DTY, according to the cycle of 12:16 Alternate punching, the weave adopts square flat, and the gray cloth is made on a single-axis air-jet loom.

[0055] The gray cloth goes through scouring→relaxation→intermediate shaping→continuous reduction→dyeing→resin processing→finishing and shaping→mechanical soft processing. Finally, a finished product is produced. The weight of the finished product is 91g / m 2 .

[0056] Among them, relaxation processing conditions: temperature 110°C, heat preservation 20min. Intermediate shaping processing conditions: temperature 180°C, operating speed 50m / min, fan power 30Hz. Continuous reduction conditions: reduction rate of 7%. Dyeing conditions: 130℃*20min for disperse dyeing. Resin processing conditions: temperature 150°C, r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com