A kind of copper base-graphite self-lubricating composite material and preparation method thereof

A composite material and self-lubricating technology, applied in the field of friction materials, can solve the problems of unfavorable copper and excellent electrical conductivity of graphite self-lubricating performance, low density of copper-based-graphite composite materials, uncontrollable distribution range of graphite, etc., so as to improve the interface bonding capacity, reducing the amount of graphite, reducing the effect of splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

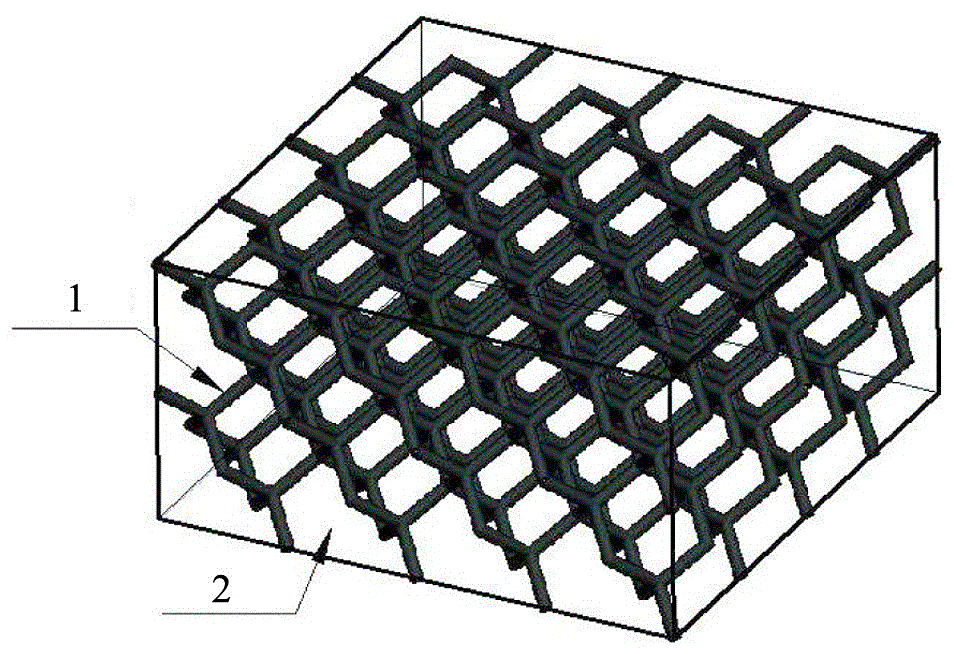

[0025] A copper-based-graphite self-lubricating composite material and a preparation method thereof, the copper-based-graphite self-lubricating composite material is composed of a copper alloy and a three-dimensional graphite skeleton, and the components of the copper alloy are Cu and MoS 2 , SiC, MoS 2 The mass fraction of Cu is 2%, SiC accounts for 0.5% of Cu, and the three-dimensional graphite skeleton accounts for 6% of the copper alloy. The graphite powder used is 200 mesh, and the phenolic resin powder is 600 mesh. head.

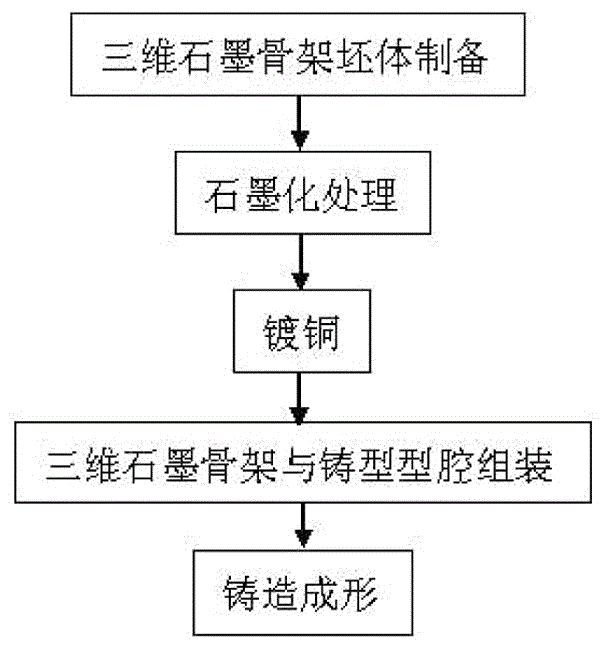

[0026] Concrete preparation steps are as follows:

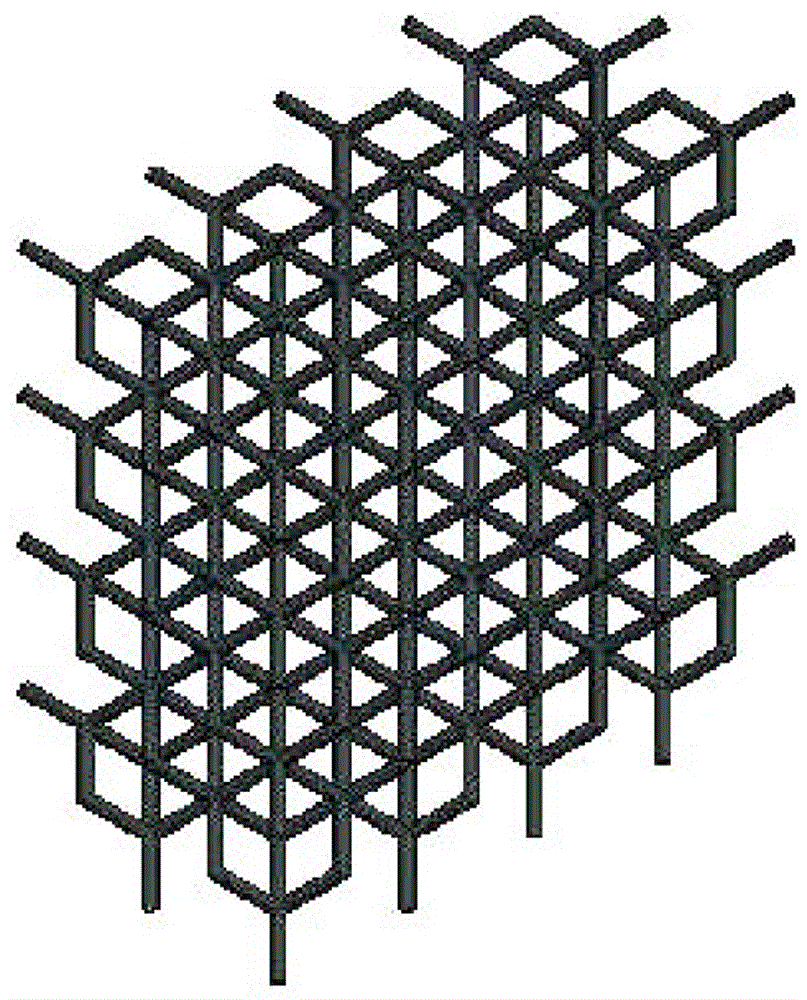

[0027] Step 1: According to the formation mechanism and strength theory of self-lubricating film, design the following figure 1 The three-dimensional graphite framework structure shown. The volume fraction of pores is 76%, the hole size is 2.0mm, and the characteristic size of graphite skeleton is 0.6mm.

[0028] Step 2: uniformly mix the graphite powder and phenolic resin powder as described abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com