Ultraviolet cured resin coated modified bamboo fiber and preparation method thereof

A technology of curing resin and ultraviolet light, applied in epoxy resin coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of easy water absorption, decreased mechanical properties, accelerated aging of bamboo fibers, and achieves simple processing technology, mechanical The effect of improving performance and reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

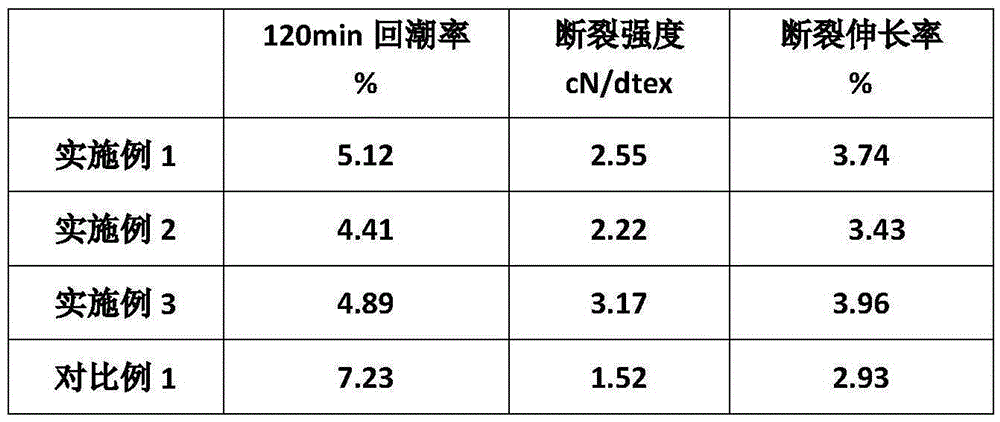

Embodiment 1

[0028] The modified bamboo fiber contains 100g of bamboo fiber and 10g of ultraviolet curable resin.

[0029] Get 100g of bamboo fiber after washing treatment, get 375g of epoxy acrylate, 125g of 2-methacrylic acid isocyanate, 6.25g of 1-hydroxycyclohexyl acetophenone, 0.63g of polymerization inhibitor hydroxyanisole, mix uniformly and configure to obtain ultraviolet light-curing composition. Put 100g of bamboo fiber into a metal mesh bag and completely immerse it in the UV-curable composition. After dipping for 5 minutes, pull the mesh bag, place it in a centrifuge and shake it at a speed of 2000r / min for 1 minute, and spread it loosely on the poly The tetrafluoroethylene plate is sent to a UV curing device for irradiating for 1 minute. After the surface resin layer is cured, the bamboo fiber coated with the UV curing resin is obtained, which is designated as bamboo fiber 1.

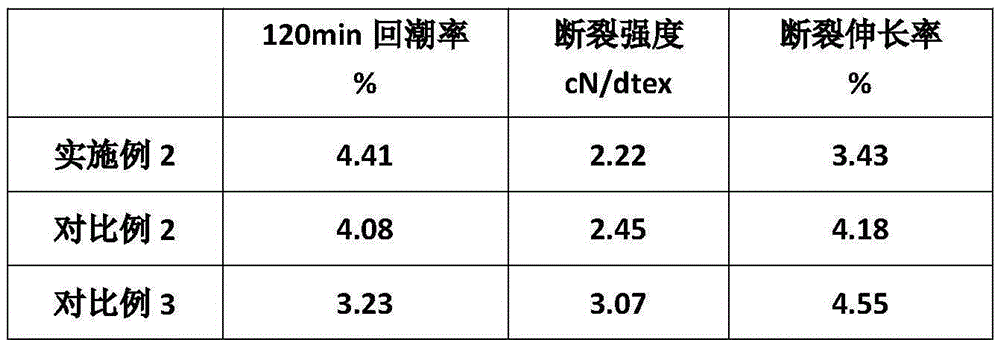

Embodiment 2

[0031] The modified bamboo fiber contains 100g of bamboo fiber and 7g of ultraviolet curable resin.

[0032] Take 100g of bamboo fiber after washing and cutting, take 1000g of polyurethane acrylate, 400g of isodecyl acrylate, 14g of α-hydroxy ketone, and 3.4g of polymerization inhibitor hydroxyethyl methacrylate, and mix them evenly to obtain ultraviolet light Curing composition. Put 100g bamboo fiber into a metal mesh bag and completely immerse it in the UV-curable composition, pull the mesh bag after dipping for 5 minutes, and place it in a centrifuge and shake it for 3 minutes at a speed of 1000r / min, then spread it loosely on the poly The tetrafluoroethylene plate is sent to the ultraviolet light curing device for irradiation for 5 minutes. After the surface resin layer is cured, the bamboo fiber coated with the ultraviolet light curing resin is obtained, which is recorded as bamboo fiber 2.

Embodiment 3

[0034] The modified bamboo fiber contains 100g of bamboo fiber and 19g of ultraviolet curable resin.

[0035] Take 100g of bamboo fiber after washing and cutting, take 7500g of alicyclic epoxy resin, 2816g of isodecyl acrylate, 94g of α-hydroxy ketone, 28g of polymerization inhibitor hydroxyanisole, and mix them evenly to obtain ultraviolet light Curing composition. Put 100g of bamboo fiber into a metal mesh bag and completely immerse it in the UV-curable composition. After soaking for 10 minutes, pull the mesh bag, place it in a centrifuge and shake it at a speed of 100r / min for 10 minutes, and spread it loosely on the poly The tetrafluoroethylene plate is sent to a UV curing device for 10 minutes of irradiation. After the surface resin layer is cured, the bamboo fiber coated with the UV curing resin is obtained, which is designated as bamboo fiber 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com