K2O-Na2O-Nb2O5-SiO2-B2O3 system glass ceramic material used for energy storage, and preparation method thereof

A technology of k2o-na2o-nb2o5-sio2-b2o3 and glass ceramics, which is applied in the field of glass ceramics materials and their preparation, can solve the problems of high breakdown field strength and cannot be prepared, and achieves high breakdown field strength and easier uniformity Mixing, the effect of small porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

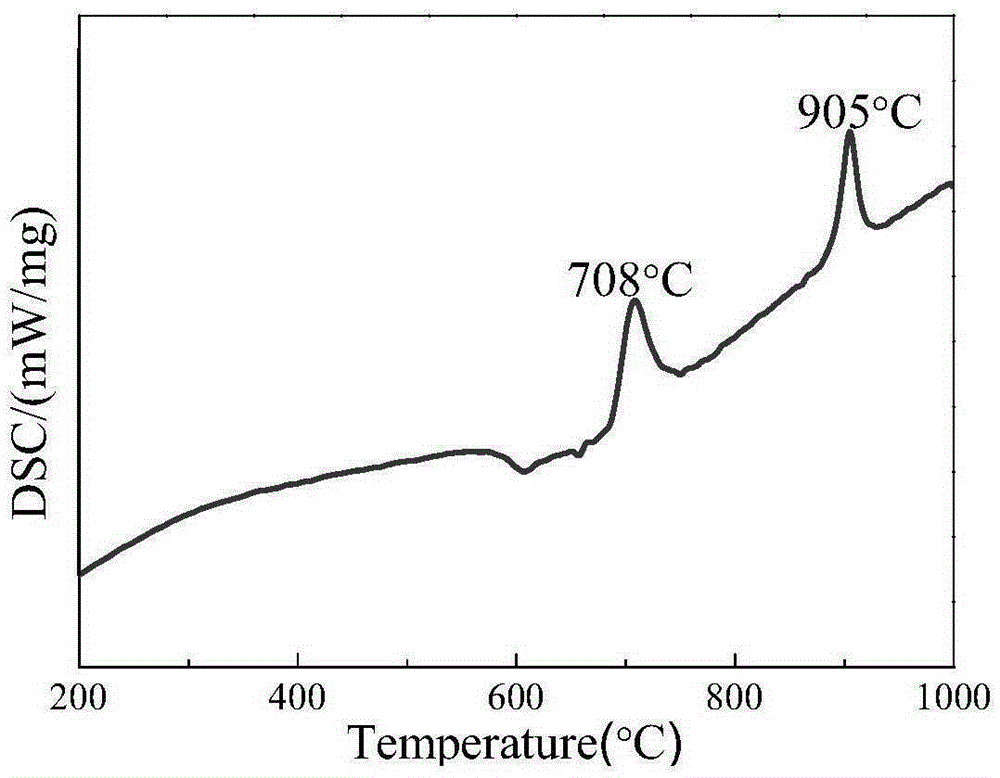

[0029] The crystallization treatment of the glass sample in this embodiment: heat preservation at 708° C. for 1 hour and heat preservation at 905° C. for 4 hours.

[0030] The preparation method of the glass-ceramic material of the present embodiment comprises the following steps:

[0031]1) The sodium potassium niobate glass-ceramic material in this embodiment is made of a material ratio of 15:15:30:4:2:3, taking K 2 CO 3 , Na 2 CO 3 , Nb 2 o 5 , SiO 2 , H 3 BO 3 and BaF 2 mix.

[0032] 2) When heating the quartz crucible with the furnace from room temperature to 1100°C, start adding the mixture, then continue heating to 1350°C, and keep the temperature at 1350°C for 30 minutes to melt the mixture evenly to obtain a mixed molten material; put the mixed molten material on the copper plate After molding, put it into the furnace quickly and anneal at 600°C for 7 hours to obtain the annealed glass;

[0033] 3) After holding at 708°C for 1h, continue to hold at 905°C fo...

Embodiment 2

[0036] The crystallization treatment of the glass sample in this embodiment: heat preservation at 708° C. for 4 hours and heat preservation at 905° C. for 1 hour, and other conditions are the same as in Embodiment 1.

Embodiment 3

[0038] The crystallization treatment of the glass sample in this embodiment: heat preservation at 708° C. for 2 hours and heat preservation at 905° C. for 3 hours, and other conditions are the same as in Embodiment 1.

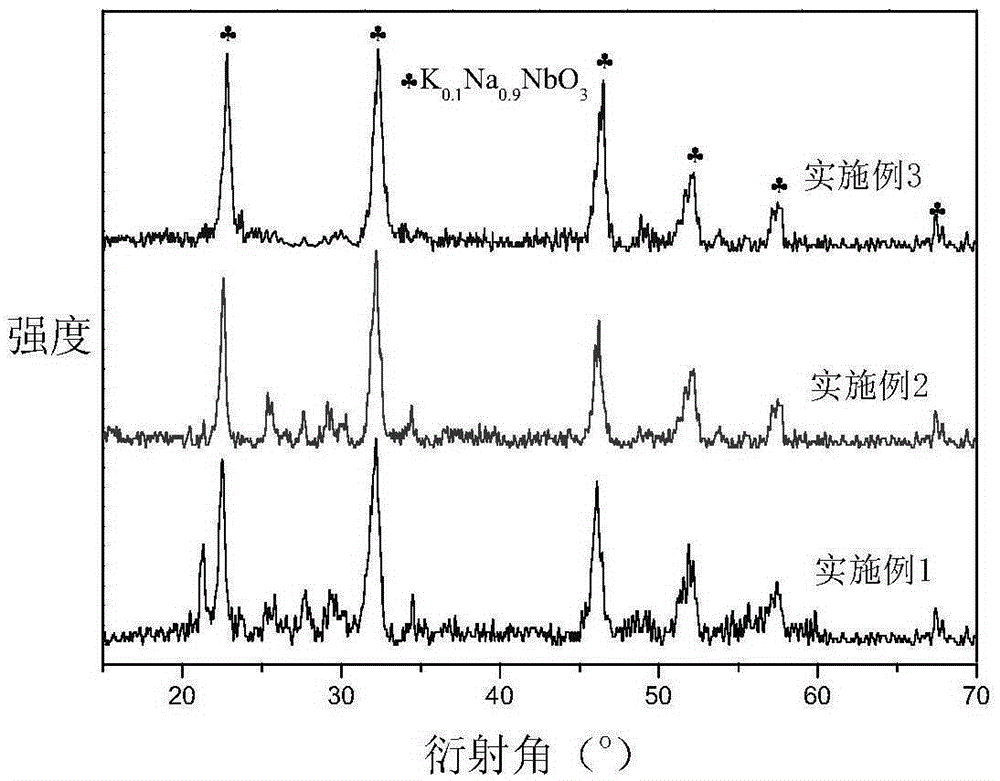

[0039] figure 2 For the X-ray diffraction analysis of the above three examples, the effects of different crystallization treatments on the degree of crystallization and crystallization purity are shown. It can be seen that under the crystallization treatment in Example 1, due to the long holding time at the low-temperature crystallization temperature and the short holding time at the high-temperature crystallization temperature, it is not conducive to the growth of crystal grains, and the glass phase still exists in large quantities, so that impurities There are many peaks. In Example 2, the prolonged holding time at high temperature is beneficial to the formation of the main crystal phase, but at the same time it is also beneficial to the growth of other sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com