Process and system for treating high salinity wastewater in coal chemical industry

A technology of high-salt wastewater and treatment process, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Solve problems such as complex crystalline solid components, and achieve the effects of saving water resources, high reliability, and reducing the scale of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

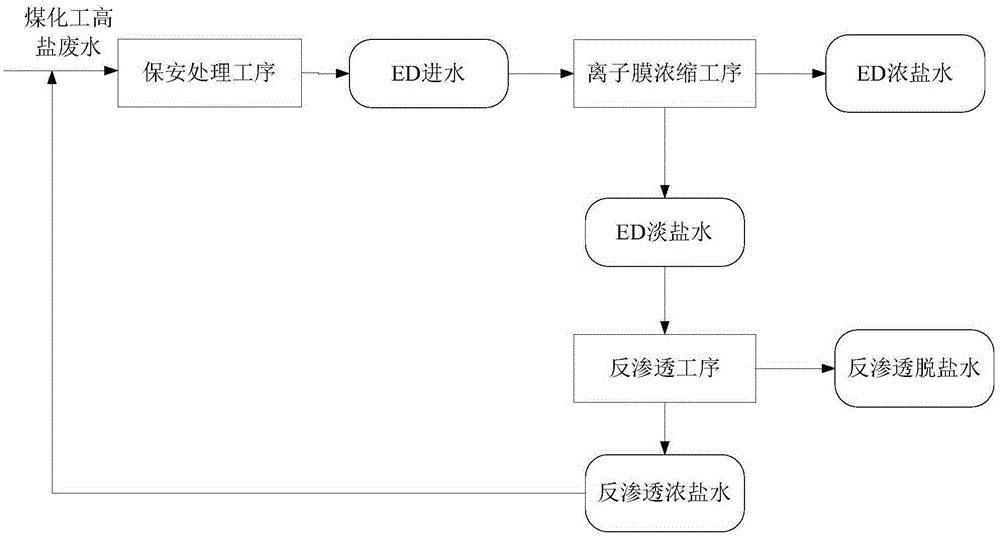

[0054] see figure 1 , the treatment system of the coal chemical high-salt wastewater of the present embodiment comprises:

[0055] Mechanical filter tank, design the agent dosing point at the wastewater inlet of the mechanical filter tank, and use appropriate amount of flocculant and other chemicals to carry out flocculation, sedimentation and filtration treatment on the high-salt wastewater of the coal chemical industry, and the high-salt wastewater treated by the mechanical filter tank enters Nanofiltration membrane filter;

[0056] Nanofiltration membrane filter; the inlet water of the nanofiltration membrane filter is the high-salt wastewater treated by the mechanical filter tank, and the outlet water is the ED inlet water. The pore diameter of the nanofiltration membrane in this embodiment is 10 nanometers, and the operating pressure is generally 1.0 MPa; the operating pressure of the nanofiltration membrane in the present embodiment is generally 0.5~2.0MPa;

[0057] Io...

Embodiment 2

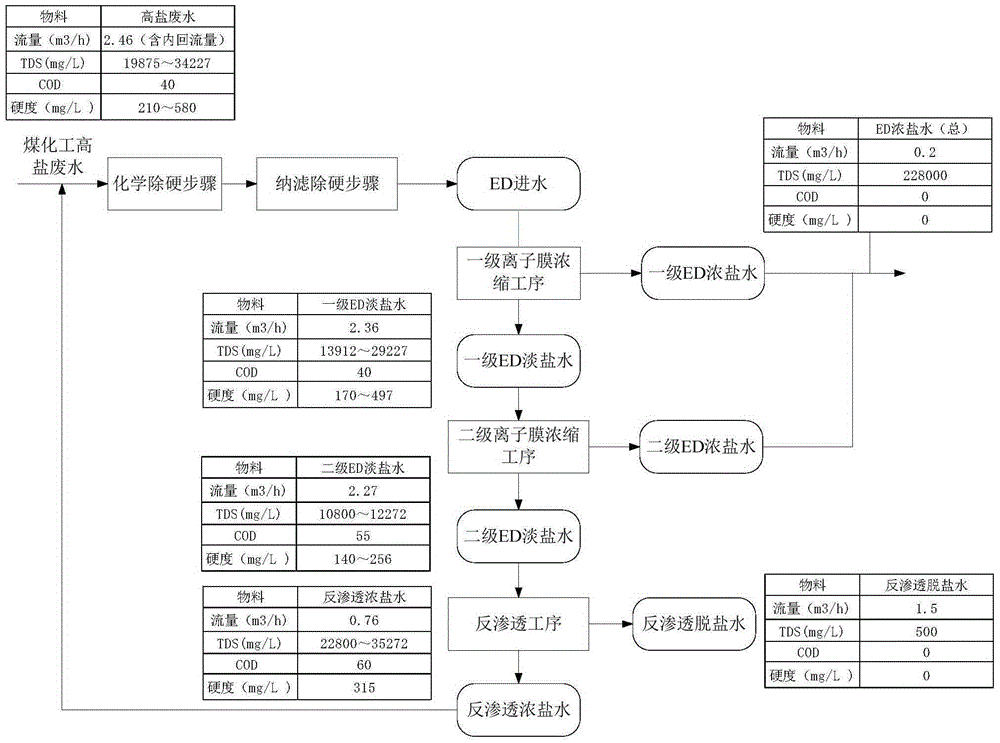

[0064] Other equipment in this embodiment is the same as in Embodiment 1, except that the ionic membrane reactor in this embodiment includes a primary ionic membrane reactor and a secondary ionic membrane reactor. The first-level ED concentrated brine from the first-level ionic membrane reactor enters the second-level ionic membrane reactor for further processing to obtain the second-level ED light brine and the second-level ED concentrated brine. The first ED light brine and the second ED light brine are mixed to obtain ED light brine, and this mixed ED light brine enters the reverse osmosis filter. In addition, the secondary ED concentrated brine can enter the evaporator to obtain high cleanliness salt.

[0065] The ionic membrane in Example 2 uses a special monovalent ion-selective homogeneous ionic membrane CIMS / AMS to form an ionic membrane device. The four membrane stacks are arranged in two stages, and the concentration difference between the two phases can reach 15 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com