A process for treating produced water in a sour gas field

A gas field produced water and treatment technology technology, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of no evaporation of mother liquor and difficulty in zero discharge of gas production wastewater, etc. To achieve the effect of reducing dosage, reducing environmental hazards, and reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

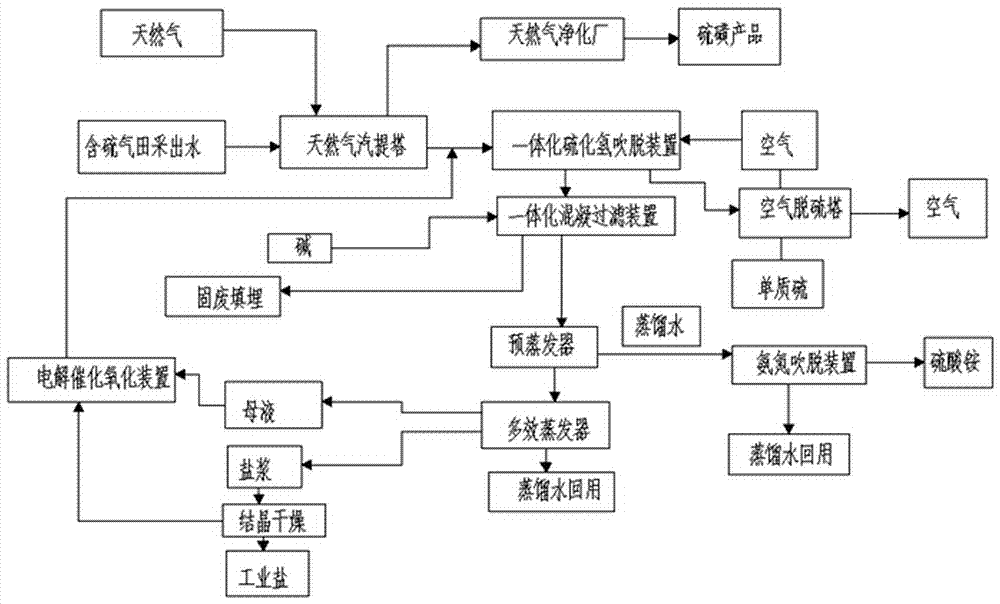

[0035] A treatment process for produced water from a sulfur-containing gas field, characterized in that it includes the following process steps:

[0036] The first step: stripping the produced water from the sour gas field;

[0037] The second step: the liquid after the first step is subjected to air blowing to remove sulfur;

[0038] The third step: pre-evaporating the liquid after the second step, after the liquid is pre-evaporated by 30%, perform multi-effect evaporation, the distilled water produced by multi-effect evaporation and pre-evaporation is subjected to ammonia nitrogen blow-off treatment, and the mother liquor produced by multi-effect evaporation Electrolytic catalytic oxidation treatment is carried out.

[0039] Specifically, as figure 1 Shown, processing step of the present invention is as follows:

[0040] The produced water from the sulfur-containing gas field is passed into the natural gas stripper, and then natural gas is passed into the natural gas stri...

Embodiment 2

[0048] A treatment process for produced water from a sulfur-containing gas field, characterized in that it includes the following process steps:

[0049] The first step: stripping the produced water from the sour gas field;

[0050] The second step: the liquid after the first step is subjected to air blowing to remove sulfur;

[0051] The third step: pre-evaporating the liquid after the second step, after the liquid is pre-evaporated by 25%, perform multi-effect evaporation, the distilled water produced by multi-effect evaporation and pre-evaporation is subjected to ammonia nitrogen blow-off treatment, and the mother liquor produced by multi-effect evaporation Electrolytic catalytic oxidation treatment is carried out.

[0052] Specifically, the processing steps of the present invention are as follows:

[0053] The produced water from the sour gas field is passed into the natural gas stripper, and then natural gas is passed into the natural gas stripper. The amount of natural...

Embodiment 3

[0062] A treatment process for produced water from a sulfur-containing gas field, characterized in that it includes the following process steps:

[0063] The first step: stripping the produced water from the sour gas field;

[0064] The second step: the liquid after the first step is subjected to air blowing to remove sulfur;

[0065] The third step: pre-evaporate the liquid after the second step, after the liquid is pre-evaporated by 20%, perform multi-effect evaporation, the distilled water produced by multi-effect evaporation and pre-evaporation is subjected to ammonia nitrogen blow-off treatment, and the mother liquor produced by multi-effect evaporation Electrolytic catalytic oxidation treatment is carried out.

[0066] Specifically, the processing steps of the present invention are as follows:

[0067]The produced water from the sour gas field is passed into the natural gas stripping tower, and then natural gas is passed into the natural gas stripping tower. The amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com