Preparation method of ferriferrous oxide@nitrogen doped carbon compound

A technology of ferroferric oxide and nitrogen-doped carbon, which is applied in the direction of ferric oxide, iron oxide/iron hydroxide, etc., can solve the problems of low degree of carbonization of activated carbon and the inability to control the thickness of the carbon coating layer, etc. Achieve high degree of carbonization and improve electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

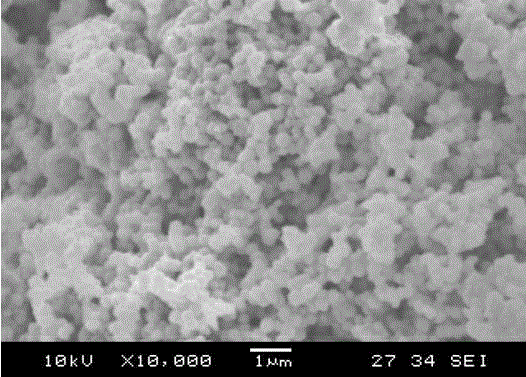

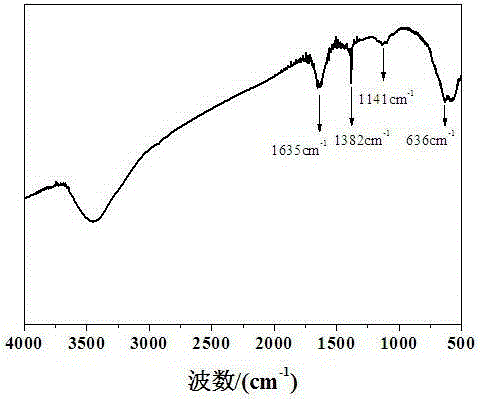

Image

Examples

Embodiment 1

[0019] (1) Mix analytically pure aniline with a volume ratio of 0.5:1 and hydrochloric acid with a concentration of 0.01mol / L to prepare aniline hydrochloric acid solution.

[0020] (2) Under room temperature and mechanical stirring conditions, add ferric oxide and distilled water into a mechanical stirrer and stir, and disperse ferric oxide in distilled water to prepare a ferric oxide solution with a mass concentration of 10 mg / mL.

[0021] (3) After stirring for 40 minutes, add 1 mL of the aniline hydrochloric acid solution obtained in step (1) to 10 mL of the ferric oxide solution obtained in step (2), and stir mechanically for 40 minutes.

[0022] (4) Add 1 mL of 30% hydrogen peroxide dropwise to the solution obtained in step (3), stir and react for 12 hours, magnetically separate, wash the precipitate with water, and dry at 60°C for 24 hours to obtain trioxide Iron polyaniline nanoparticles.

[0023] (5) Using a high temperature of 900 ° C, the polyaniline nanoparticles ...

Embodiment 2

[0025] (1) Mix analytically pure aniline with a volume ratio of 2:3 and hydrochloric acid with a concentration of 0.01mol / L to prepare aniline hydrochloric acid solution.

[0026] (2) Under room temperature and mechanical stirring conditions, add ferric oxide and distilled water into a mechanical stirrer and stir, and disperse ferric oxide in distilled water to prepare a ferric oxide solution with a mass concentration of 5 mg / mL.

[0027] (3) After stirring for 30 minutes, add 1 mL of the aniline hydrochloric acid solution obtained in step (1) to 10 mL of the ferric oxide solution obtained in step (2), and stir mechanically for 40 minutes.

[0028] (4) Add 3 mL of 30% hydrogen peroxide dropwise to the solution obtained in step (3), stir and react for 12 hours, magnetically separate, wash the precipitate with water, and dry at 60°C for 24 hours to obtain trioxide Iron polyaniline nanoparticles.

[0029] (5) Using a high temperature of 800 ° C, the carbonization step (4) obtain...

Embodiment 3

[0031] (1) Mix analytically pure aniline with a volume ratio of 4:1 and phosphoric acid with a concentration of 0.01mol / L to prepare aniline phosphoric acid solution.

[0032] (2) Under room temperature and mechanical stirring conditions, add ferric oxide and distilled water into a mechanical stirrer and stir, disperse ferric oxide in distilled water, and prepare ferric oxide solution with a mass concentration of 8mg / mL.

[0033] (3) After stirring for 35 minutes, add 1 mL of the aniline phosphoric acid solution obtained in step (1) to 10 mL of the ferric oxide solution obtained in step (2), and stir mechanically for 40 minutes.

[0034] (4) Add 3 mL of 30% hydrogen peroxide dropwise to the solution obtained in step (3), stir and react for 24 hours, magnetically separate, wash the precipitate with water, and dry at 60°C for 24 hours to obtain trioxide Iron polyaniline nanoparticles.

[0035] (5) Using a high temperature of 700°C, carbonizing the ferric iron tetroxide polyanil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com