Detection test piece and method for detecting curved surface processing capacity of five-axis numerical control machine tool

A technology for CNC machine tools and surface processing, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of lack of effective means of processing capacity, difficulty in realizing error factor decoupling and machine tool error traceability, etc. Geometric properties of a single effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The method for detecting the surface processing capability of a five-axis linkage CNC machine tool model V51030ABJ includes the following steps:

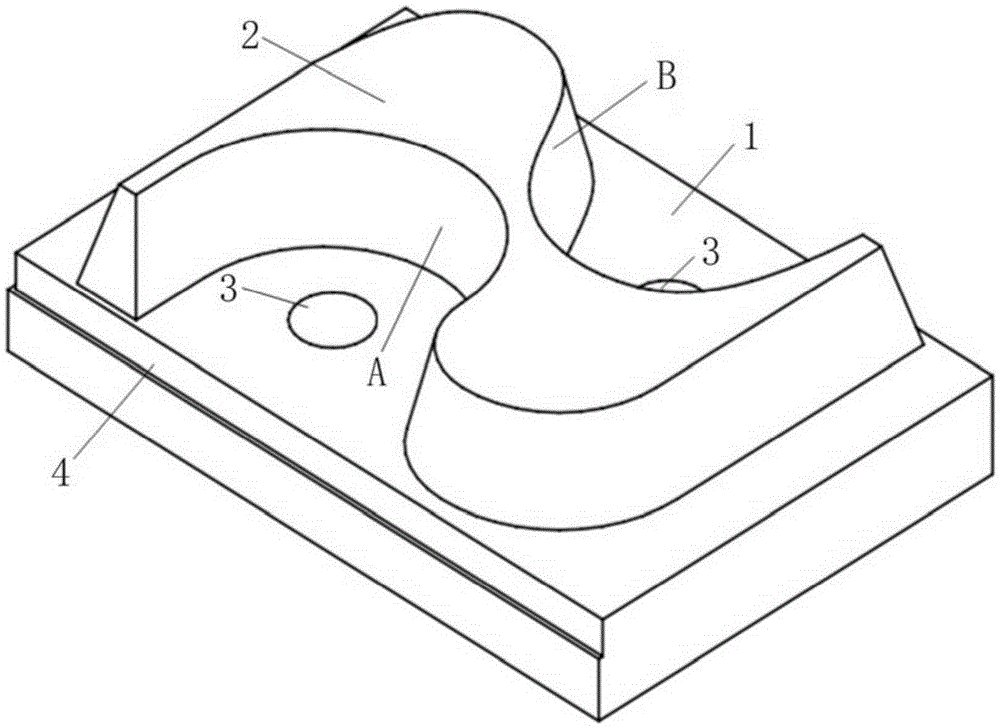

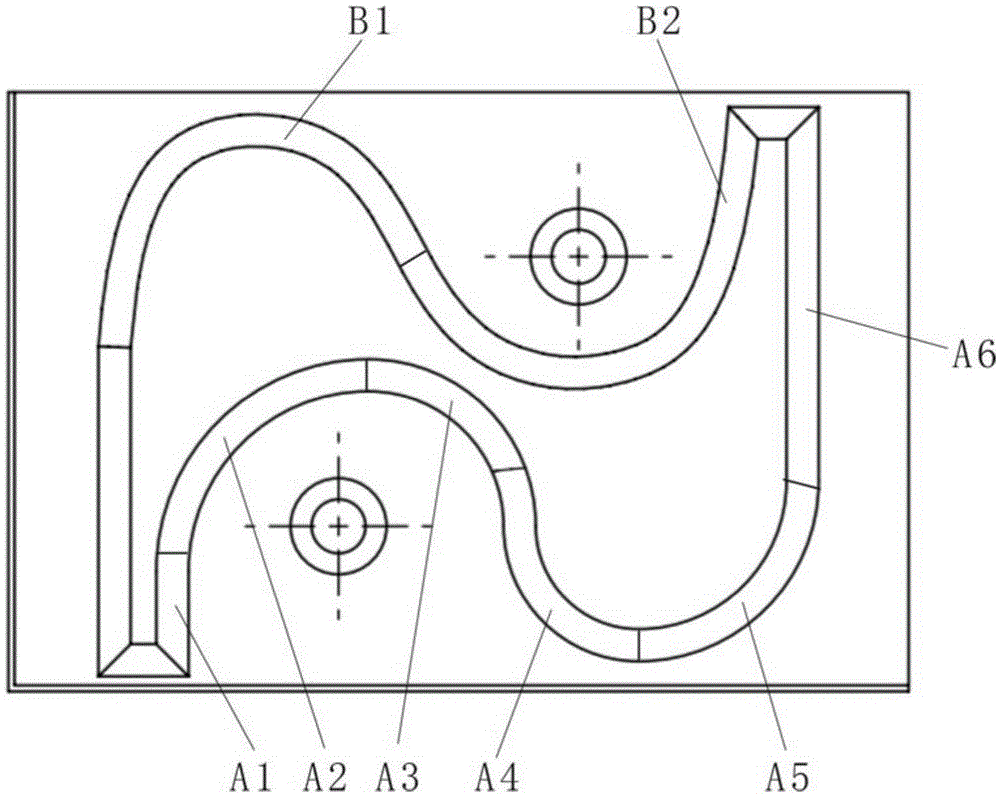

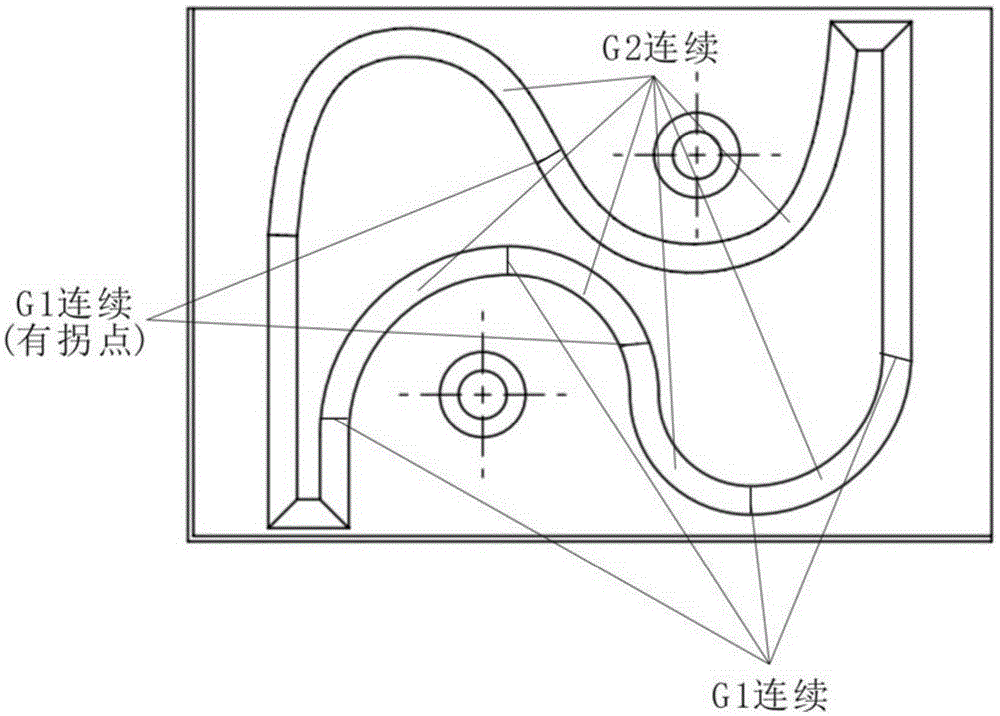

[0045] Step 1. Geometrically model the test piece by general-purpose CAD software. The thickness of the base 1 and the height of the curved edge 2 are both 40mm, and the angle between the A surface and the B surface of the curved edge 2 and the plane of the base 1 Both are 105°.

[0046] Step 2. In the specimen model established in step 1, set the milling path. The milling process is divided into rough machining, semi-finishing machining and finishing machining. Pre-commands (x, y, z, i, j , k), to generate the NC codes (X, Y, Z, A, B) of each coordinate axis during the processing of the specimen.

[0047] Step 3. The blank material is 7075-t7451 aluminum alloy, and the blank size is 300mm×200mm×80mm. Choose an end mill with a diameter of 20mm, and process it from top to bottom at a depth of 10mm per layer along the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com