Preparation method for synthesizing Cu-SAPO-34 molecular sieve based catalyst through hydrogen fluoride modified one-step method

A technology of cu-sapo-34 and hydrogen fluoride, applied in molecular sieve catalysts, physical/chemical process catalysts, separation methods, etc., can solve the problems of poor hydrothermal stability of catalysts, uncontrollable grain size, long crystallization reaction time, etc. Achieve the effects of reducing structural defects, widening the reaction temperature window, and accelerating the crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve copper sulfate in deionized water and stir for 0.5 hours, add tetraethylenepentamine and stir for 1 hour to form a copper amine complex solution, then add pseudo-boehmite, orthophosphoric acid, and silica sol in sequence to the copper amine complex solution and Stirring was continued for 2 hours, and finally morpholine was added and stirred for 2 hours to obtain a fully stirred initial gel. The charging amount of each reaction raw material has following molar ratio, Al 2 o 3 : 1.8P 2 o 5 : 1.2SiO2 2 : 100H 2 O: 1 copper sulfate-tetraethylenepentamine: 1 morphophenanthroline. Put the fully stirred gel in a hydrothermal reaction kettle, react at 200°C for 5 days, cool to room temperature, centrifugally filter, wash with deionized water, dry at 100°C for 12 hours, and calcinate in a muffle furnace at 550°C , to obtain Cu-SAPO-34 molecular sieve catalyst.

Embodiment 2

[0028] The difference between Example 2 and Example 1 is that hydrogen fluoride is introduced into the initial gel, that is, hydrogen fluoride is added after the initial gel is formed. The addition amount of reaction raw material has following molar ratio, 0.04 hydrogen fluoride: Al 2 o 3 : 1.8P 2 o 5 : 1.2SiO2 2 : 100H 2O: 1 copper sulfate-tetraethylenepentamine: 1 morphophenanthroline. Put the fully stirred gel in a hydrothermal reaction kettle, react at 175°C for 1.5 days, cool to room temperature, centrifugally filter, wash with deionized water, dry at 100°C for 12 hours, and calcinate in a muffle furnace at 550°C , to obtain Cu-SAPO-34 molecular sieve catalyst.

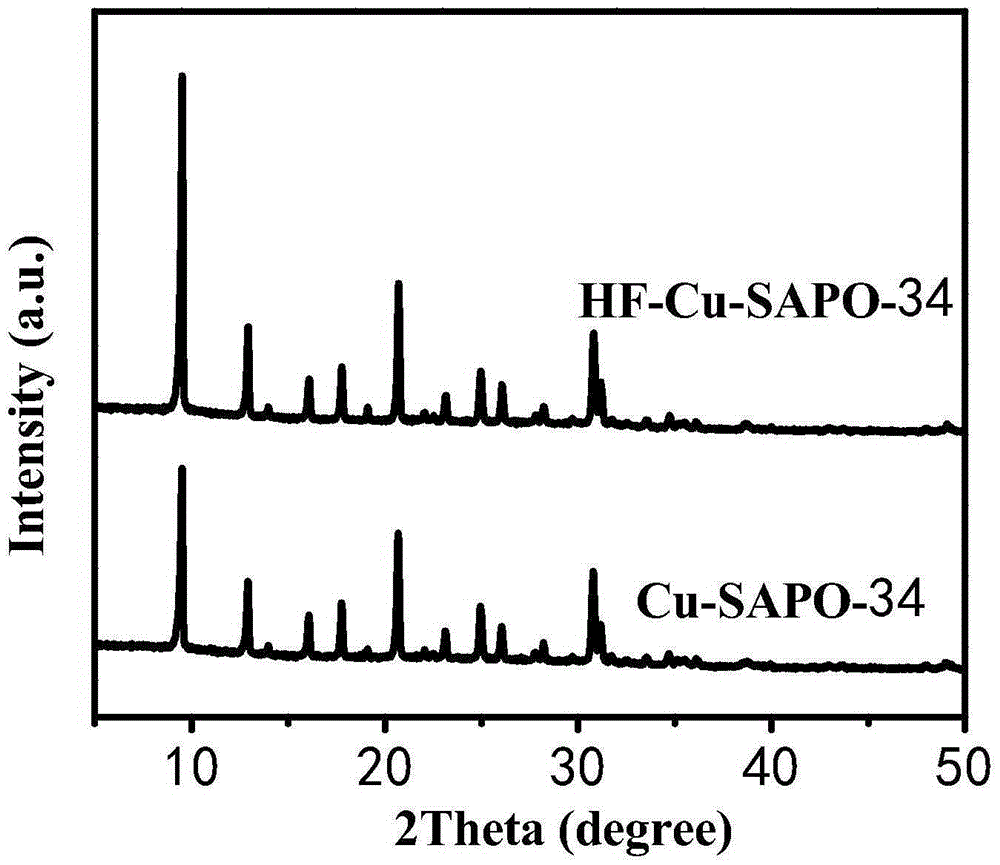

[0029] figure 1 It is the XRD pattern of the sample of Example 1 and Example 2, which shows that the SAPO-34 molecular sieve that is synthesized in situ by the one-step hydrogen fluoride modification product is a pure phase, without other miscellaneous crystals, and the crystallinity of the molecular sieve...

Embodiment 3

[0031] The feeding and feeding sequence, stirring time, hydrothermal reaction conditions and post-treatment process of sample preparation are all according to Example 2, and the addition amount of each reaction raw material has the following molar ratio, 0.04 hydrogen fluoride: Al 2 o 3 : 1.8P 2 o 5 : 1.2SiO2 2 : 100H 2 O: 0.1-2 copper sulfate-tetraethylenepentamine: 0.04-1.9 morphophenanthroline.

[0032] The ICP test of the sample shows that the hydrogen fluoride modified one-step method is used to synthesize Cu-SAPO-34 in situ, and the loading of active components can be adjusted by changing the ratio of copper amine complex and morphophenanthline double template in the initial gel. quantity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com