Mixing tank with air blowing device for lubricating oil production system

A technology of production system and preparation tank, which is applied in the direction of lubricating composition, dissolution, mixer, etc., and can solve problems such as inability to melt, grease layering, and poor anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

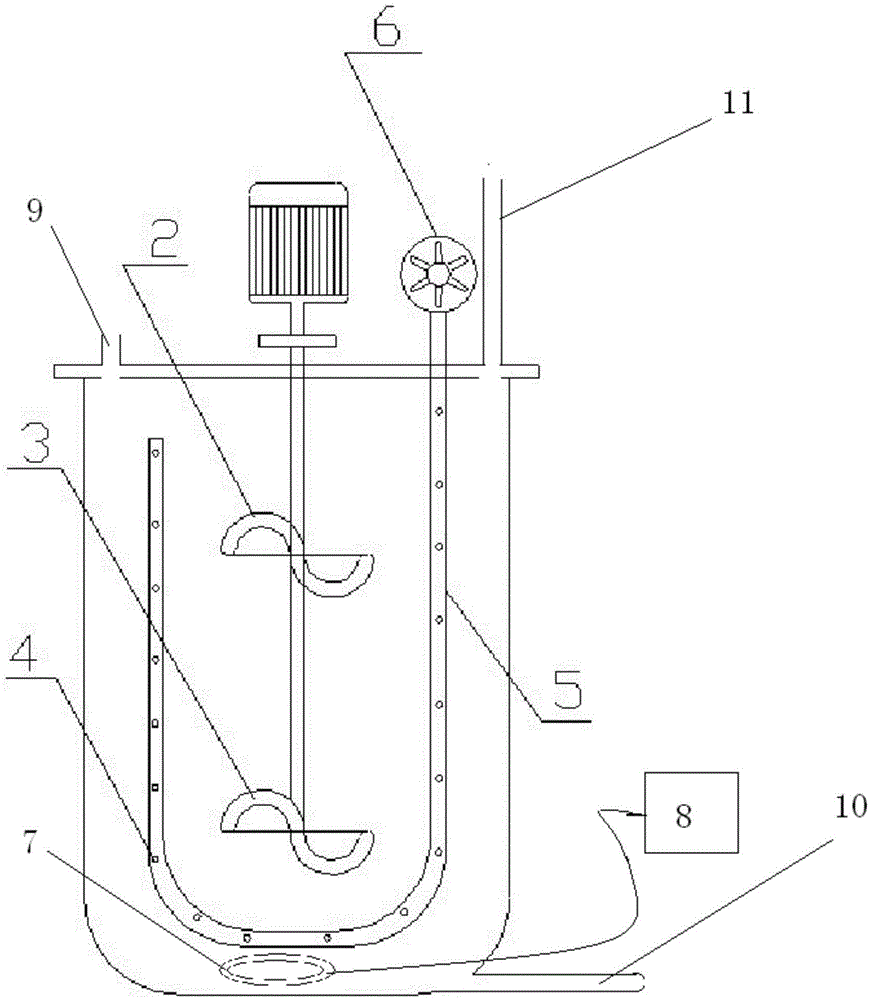

[0006] Embodiment 1: with reference to attached figure 1 . A special preparation tank for the lubricating oil production system. The preparation tank is equipped with a spiral agitator 2 and 3 and a wind agitator. The wind agitator is composed of a blowing pipe 5 and a fan 6. There are multiple blowing nozzles on the wall of the blowing pipe 4. The air inlet of the blower pipe is connected with the air outlet of the blower fan 6 . The blowing pipe 5 is H-shaped, and a plurality of blowing nozzles 4 are arranged on the opposite surface of the H-shaped pipe wall, and the horizontal pipe in the H-shaped pipe is located on one side of the stirring device. A heater is provided in the brewing tank, the signal end of the heater 7 is connected to the temperature control signal control end 8 and the operation of the heater is controlled by a temperature controller to ensure that the medium in the brewing tank is in a required constant temperature state; There is a gas outlet pipe and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com