Preparation method of porous titanium/hydroxyapatite composite material

A technology of hydroxyapatite and composite materials, which is applied in the field of preparation of porous titanium/hydroxyapatite composite materials, can solve the problems of bone resorption, atrophy implants, fall off, etc., and achieves the improvement of osteogenic activity and amount of bone formation. The effect of increasing, increasing the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

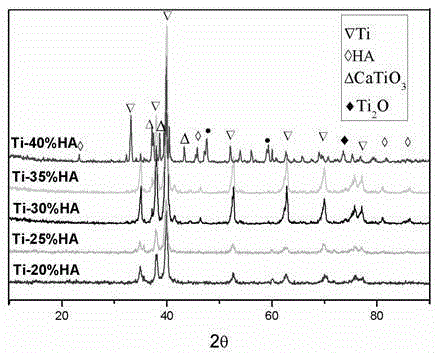

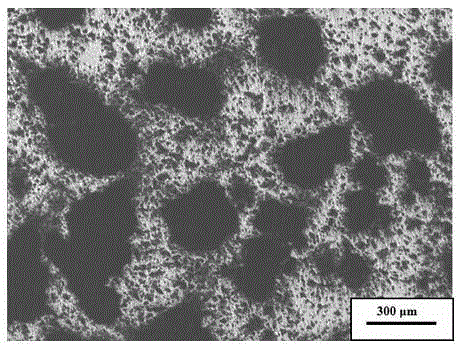

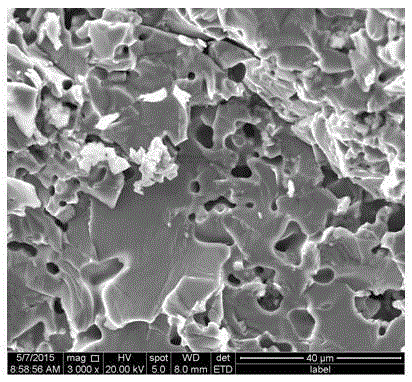

[0029] The preparation method of a biomedical porous Ti-HA composite material described in this embodiment specifically includes the following steps:

[0030] (1) Weighing: According to the mass percentage of Ti80% and HA20%, respectively weigh Ti metal powder with a particle size of 45 μm and a purity of 99.5% and HA powder with a particle size of 100 nm and a purity of 99.5%;

[0031] (2) Preparation of composite raw material powder: put the powder weighed in step (1) into the ball mill tank of the ball mill, vacuumize to 8Pa, and then ball mill and mix the powder for 2 hours to obtain the mixed Ti-HA powder;

[0032] (3) Weighing: 80% mixed Ti-HA powder, NH 4 HCO 3 20% by mass, respectively weigh the mixed Ti-HA powder and NH with an average particle size of 300 μm and a purity of analytically pure 4 HCO 3 Porogen powder;

[0033] (4) Add pore-forming factor: put the powder weighed in step (3) into the mixer and mix for 30 minutes to obtain the mixed powder;

[0034] (...

Embodiment 2

[0041] The preparation method of a biomedical porous Ti-HA composite material described in this embodiment specifically includes the following steps:

[0042] (1) Weighing: According to the mass percentage of Ti75% and HA25%, respectively weigh Ti metal powder with a particle size of 45 μm and a purity of 99.5% and HA powder with a particle size of 80 nm and a purity of 99.5%;

[0043] (2) Preparation of composite raw material powder: put the powder weighed in step (1) into the ball mill tank of the ball mill, vacuumize to 9Pa, and then ball mill and mix the powder for 3 hours to obtain the mixed Ti-HA powder;

[0044] (3) Weighing: Mixed Ti-HA powder 85%, NH 4 HCO 3 15% by mass, weigh the mixed Ti-HA powder and NH with an average particle size of 400 μm and a purity of analytically pure 4 HCO 3 Porogen powder;

[0045] (4) Add pore-forming factor: put the powder weighed in step (3) into the mixer and mix for 60 minutes to obtain the mixed powder;

[0046] (5) Preparation...

Embodiment 3

[0051] The preparation method of a biomedical porous Ti-HA composite material described in this embodiment specifically includes the following steps:

[0052] (1) Weighing: According to the mass percentage of Ti70% and HA30%, respectively weigh Ti metal powder with a particle size of 40 μm and a purity of 99.5% and HA powder with a particle size of 90 nm and a purity of 99.5%;

[0053] (2) Preparation of composite raw material powder: put the powder weighed in step (1) into the ball mill tank of the ball mill, vacuumize to 10Pa, and then ball mill and mix the powder for 4 hours to obtain the mixed Ti-HA powder;

[0054] (3) Weighing: Mixed Ti-HA powder 90%, NH 4 HCO 3 10% by mass, respectively weigh the mixed Ti-HA powder and NH with an average particle size of 500 μm and a purity of analytically pure 4 HCO 3 Porogen powder;

[0055] (4) Add pore-forming factor: put the powder weighed in step (3) into the mixer and mix for 35 minutes to obtain the mixed powder;

[0056] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com