Method for preparing anode material of lithium ion battery by high-temperature reaction of expansible graphite and zinc powder

A technology of expanded graphite and high-temperature reaction, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high oxidation degree, complicated steps, and low specific capacity of electrode materials, so as to simplify the preparation process steps, reduce oxidation degree, The effect of good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Implementation Example 1: The expandable graphite used in the experiment is the raw material for the preparation of sealing materials routinely provided by the enterprise, and the purity of the zinc powder is 99.0%. Clean the experimental equipment with deionized water and absolute ethanol.

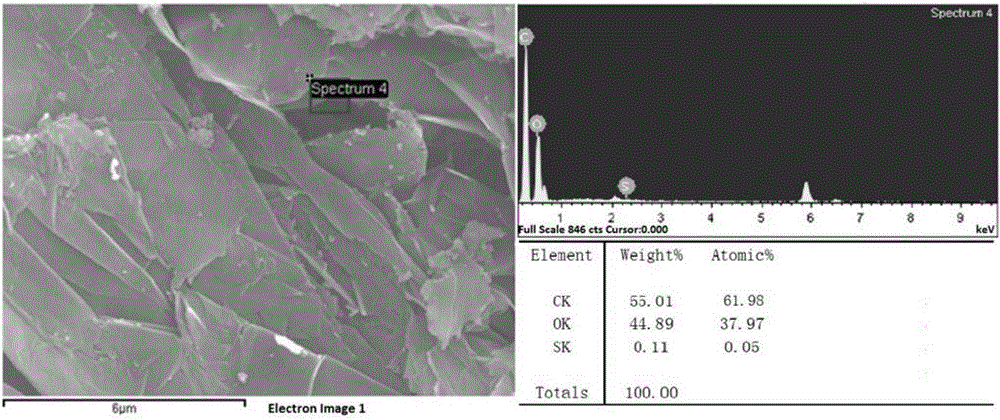

[0041] Grind the expandable graphite with an agate mortar for 30 minutes to obtain finer particles, then mix 0.25 g of the weighed expandable graphite and 1.5 g of zinc powder and grind with an agate mortar, and mix well. Heat the tube furnace to 950°C and set it to keep warm for 1 hour. During the experiment, when the temperature is about to rise to 950°C, pass high-purity argon for 20 minutes to remove the air. Put the ground sample into a quartz glass bottle with a stopper, connect and fix the stopper and the bottle body with an iron wire, and bake in an oven at 60°C for 1 hour. Put the quartz glass bottle obtained in the previous step into a 950°C tube furnace filled with argo...

Embodiment 2

[0042] Implementation Example 2: The expandable graphite used in the experiment is the raw material routinely provided by the enterprise for the preparation of sealing materials, and the purity of the zinc powder is 99.0%. Clean the experimental equipment with deionized water and absolute ethanol.

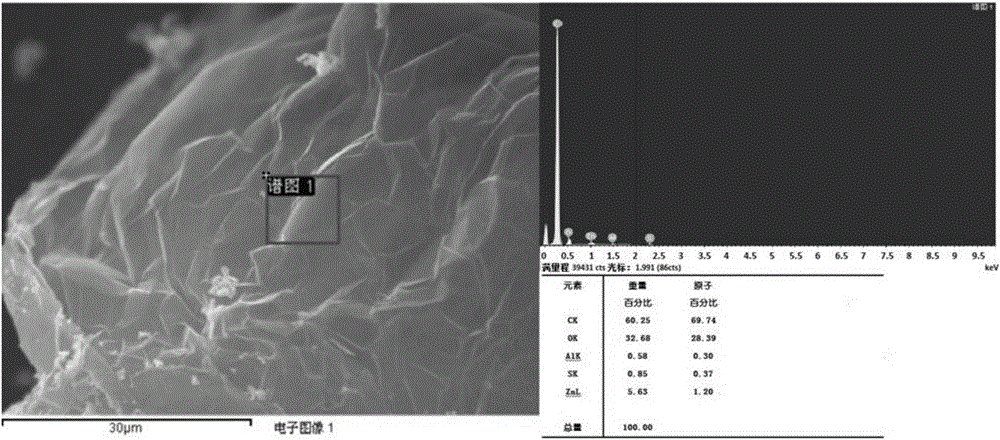

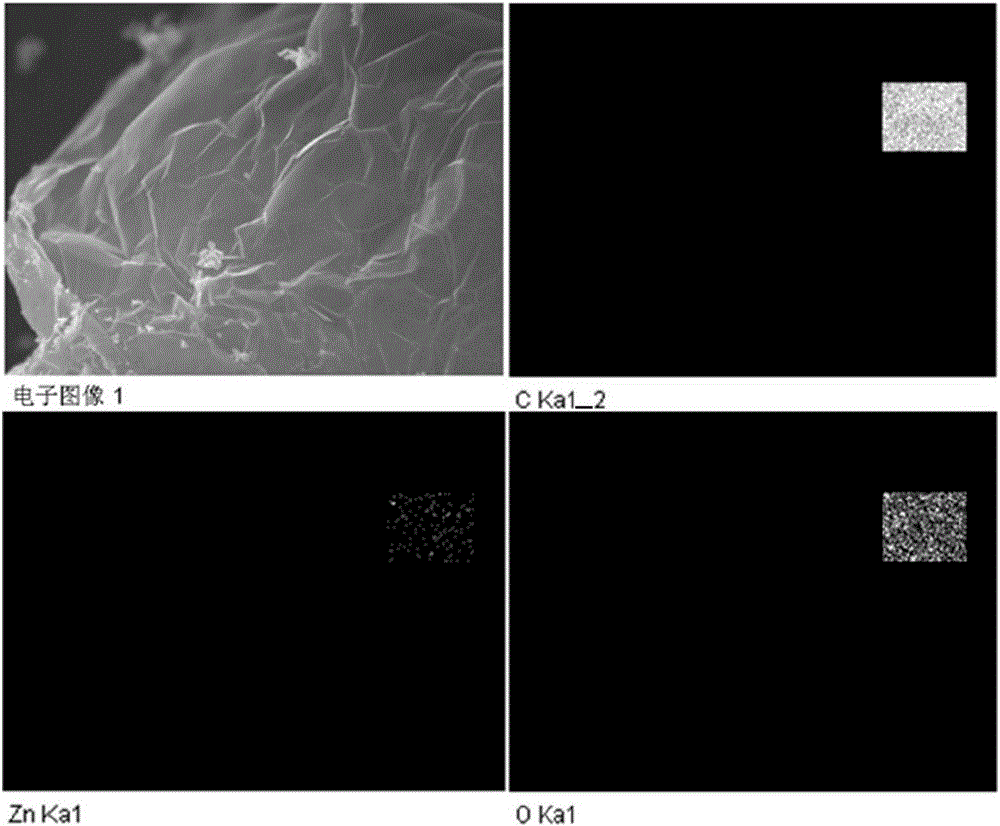

[0043]Grind the expandable graphite with an agate mortar for 30 minutes to obtain finer particles, then mix 0.3 g of the weighed expandable graphite and 0.75 g of zinc powder and grind with an agate mortar, and mix well. Heat the tube furnace to 930°C and set it to keep warm for 1 hour. During the experiment, when it shows that the temperature is about to rise to 930°C, pass high-purity argon for 20 minutes to remove the air. Put the ground sample into a quartz glass bottle with a stopper, connect and fix the stopper and the bottle body with an iron wire, and bake in an oven at 60°C for 1 hour. Put the quartz glass bottle obtained in the previous step into a tube furnace filled wi...

Embodiment 3

[0044] Implementation Example 3: The expandable graphite used in the experiment is the raw material routinely provided by the enterprise for the preparation of sealing materials, and the purity of the zinc powder is 99.0%. Clean the experimental equipment with deionized water and absolute ethanol.

[0045] Grind the expandable graphite with a mortar for 30 minutes to obtain finer particles, and then weigh 0.4 g of the expandable graphite. Heat the tube furnace to 910°C and set it to keep warm for 30 minutes. When it is about to rise to 910°C, pass high-purity argon for 20 minutes to remove the air. Put the ground expandable graphite into a quartz glass bottle with a stopper, connect and fix the stopper and the bottle body with an iron wire, and bake in an oven at 60°C for 1 hour. Put the quartz glass bottle obtained in the previous step into a tube furnace filled with argon, keep it warm for 5 minutes, take out the bottle, and cool to room temperature to obtain expanded graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com