A flue gas heat exchange device and flue gas treatment system

A flue gas treatment system and flue gas heat exchange technology, applied in the direction of indirect heat exchangers, heat exchanger types, climate sustainability, etc., can solve the problems of low waste heat utilization efficiency, air pollution, and low oil fume absorption efficiency, etc. To achieve the effect of improving utilization rate, low carbon energy saving, environmental pollution, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

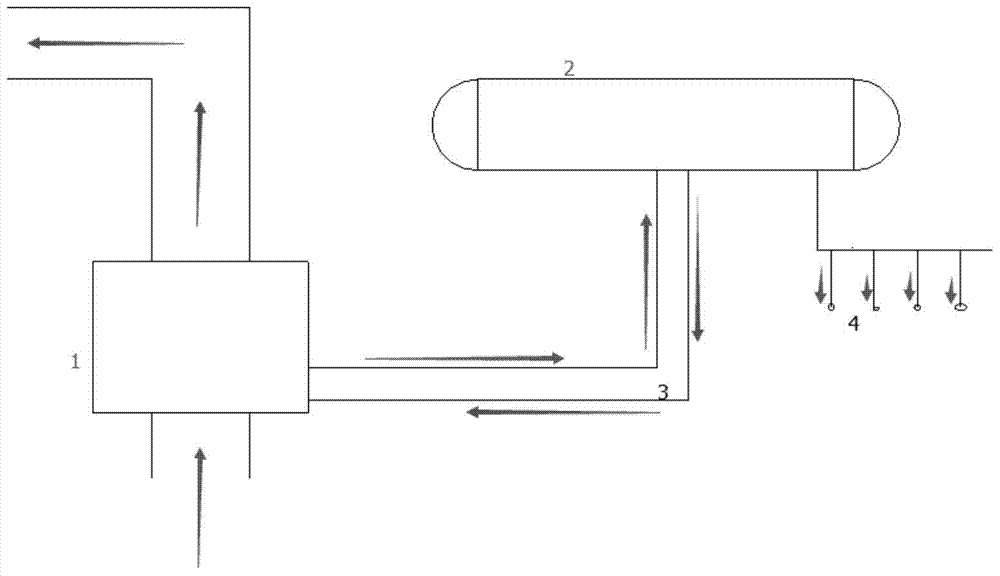

[0026] Embodiments of the flue gas treatment system of the present invention:

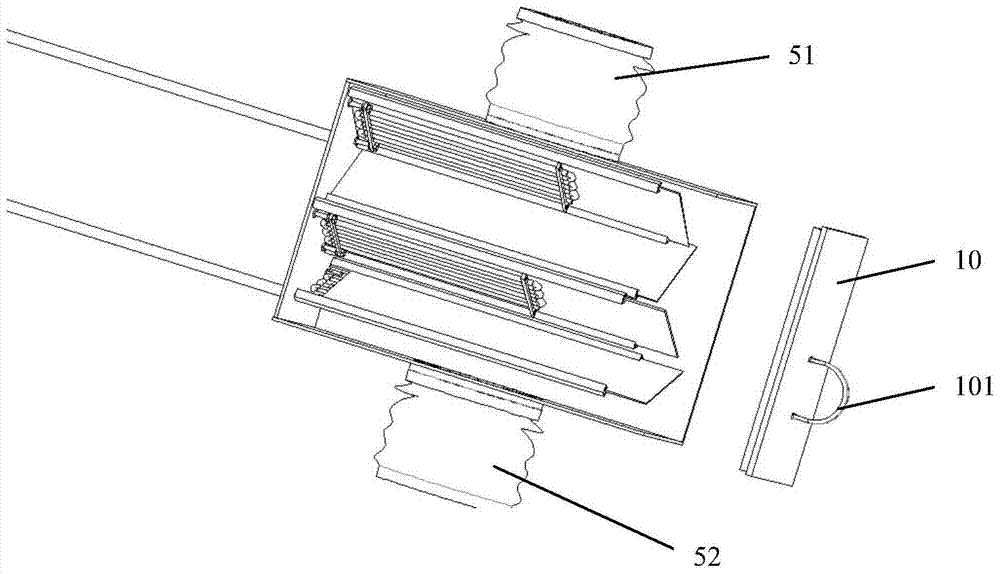

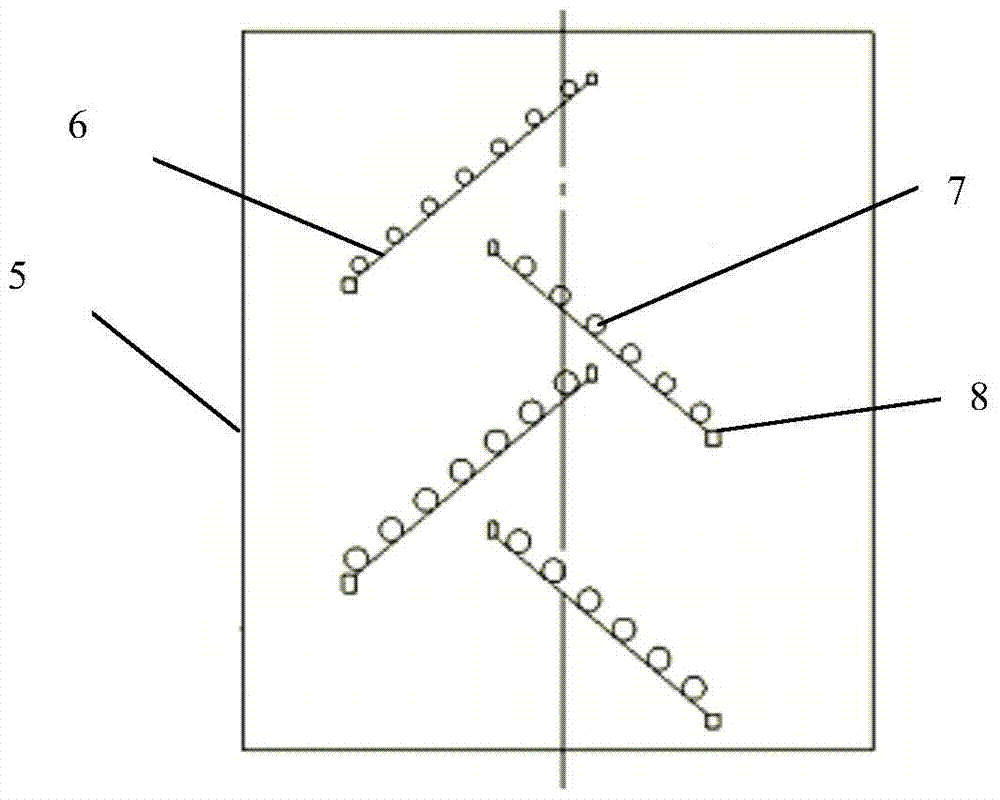

[0027] Such as Figure 1-7 As shown, the flue gas treatment system of this embodiment includes a flue gas heat exchange device 1 and a heat exchange fluid supply device connected thereto. The heat exchange fluid supply device includes a box body 5 for flue gas to pass through and a heat exchange tube 7 fixedly arranged in the box body. An air inlet pipe 51 is connected, the other end is an air outlet end, an air outlet is provided on the air outlet, an air outlet pipe 52 is connected to the air outlet, and a heat exchange plate 6 connected to the heat exchange tube is fixedly arranged in the box. The heat exchange plates are arranged staggeredly along the direction from the air inlet end to the air outlet end and form a serpentine flue gas channel in the box. The heat exchange plate is made of a material with good thermal conductivity, such as a metal material. In this embodiment, it is a copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com