Heat-preservation and sound-insulation sintered brick produced from straw and preparation method

A thermal insulation and sound insulation, preparation technology, applied in the field of building materials, can solve the problems of large demand for land and coal resources, time-consuming and labor-intensive production of sintered bricks, poor thermal insulation and sound insulation effects, etc., to achieve light weight, reduce clay usage, and thermal insulation Strong sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The heat-insulating and sound-insulating sintered brick made of straw in this embodiment is made of ingredients and water. The initial addition of the above-mentioned water is 25%-35% of the total mass of the ingredients. The above-mentioned ingredients are made of the following raw materials in weight percentages Composition: straw powder 3-5%, standard coal powder 1-3%, clay 92-96%.

[0026] The water content of the straw powder is less than 10%, the water content of the standard coal powder is less than 10%, and the water content of the clay is less than 10%.

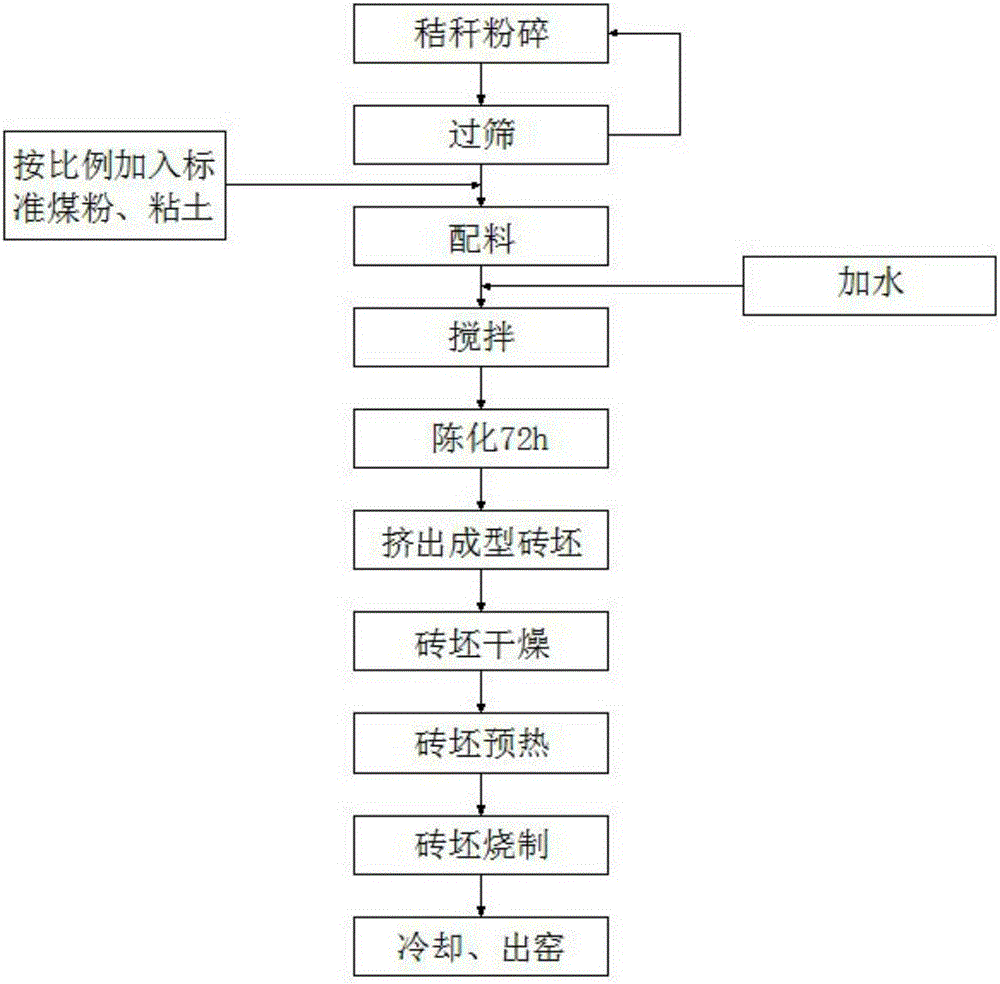

[0027] Such as figure 1 Shown, its preparation process comprises the following steps:

[0028] Step 1: Straw raw material processing, specifically, the straw raw material is pulverized by a pulverizer, and then vibrating and sieved by a sieve machine to obtain straw powder;

[0029] Step 2: batching, specifically, mixing the straw powder obtained in step 1 with standard coal and clay according ...

Embodiment 2

[0042] Embodiment 2: The heat-insulating and sound-insulating sintered brick made of straw in this embodiment is made of ingredients and water. The initial addition of the above water is 25%-35% of the total mass of the ingredients. The above ingredients are made of the following raw materials in weight percentages Composition: straw powder 4.6%, standard coal powder 1.8%, clay 93.6%.

[0043] The water content of the straw powder is less than 10%, the water content of the standard coal powder is less than 10%, and the water content of the clay is less than 10%.

[0044] Such as figure 1 Shown, its preparation process comprises the following steps:

[0045] Step 1: Straw raw material processing, specifically, the straw raw material is pulverized by a pulverizer, and then vibrating and sieved by a sieve machine to obtain straw powder;

[0046] Step 2: batching, specifically, mixing the straw powder obtained in step 1 with standard coal and clay according to the following weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com