Method of preparing regular-shaped SiO2 aerogel granules through mechanical cutting

An aerogel particle, mechanical cutting technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of poor filling, waste of raw materials, affecting the yield rate, etc. Eliminate the reflow process, reduce product cost, and facilitate the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

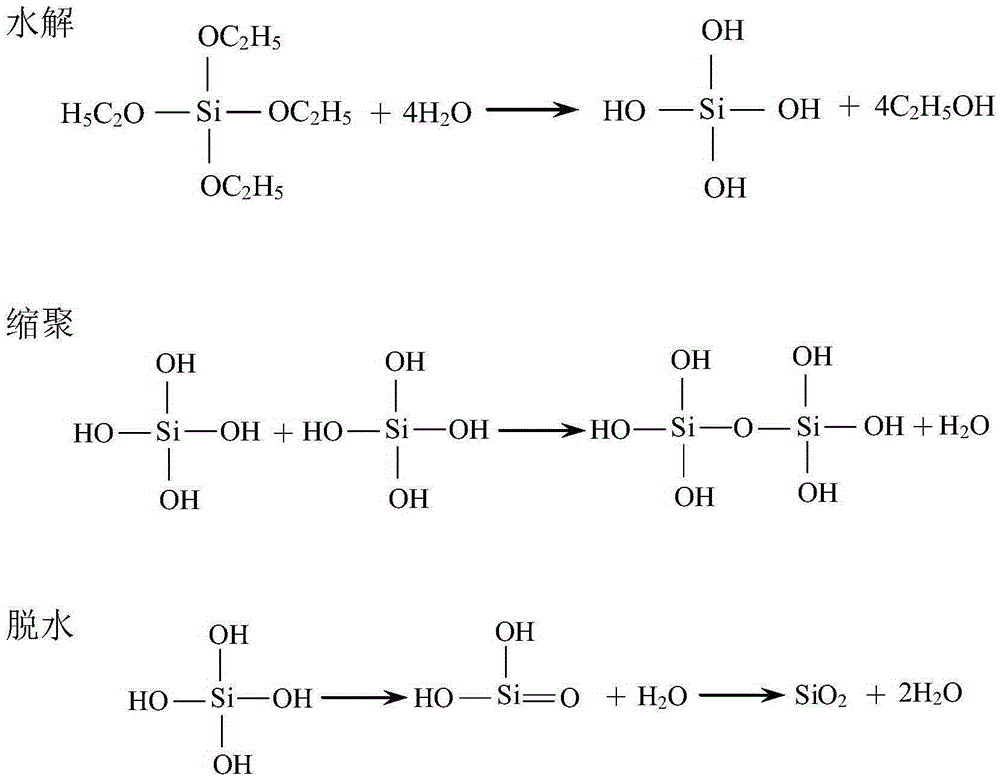

Method used

Image

Examples

Embodiment 1

[0033] Example 1: At 40°C, mix methyl orthosilicate, methanol, deionized water and dilute hydrochloric acid at a volume ratio of 1:0.5:0.1:0.0025, and stir for 0.1h to obtain a sol. The volume ratio of ester to ammonia water is 1:0.025. Add ammonia water, stir and mix for 1 hour, then let it stand. After gelation, use mechanical cutting to obtain silica gel particles with regular shapes, and age them with ethanol at 40℃ The gel particles are replaced with ethanol once every 6h, replaced 4 times, and then replaced with n-hexane 4 times, 6h each time, and dried under normal pressure to obtain silica aerogel particles with a regular shape.

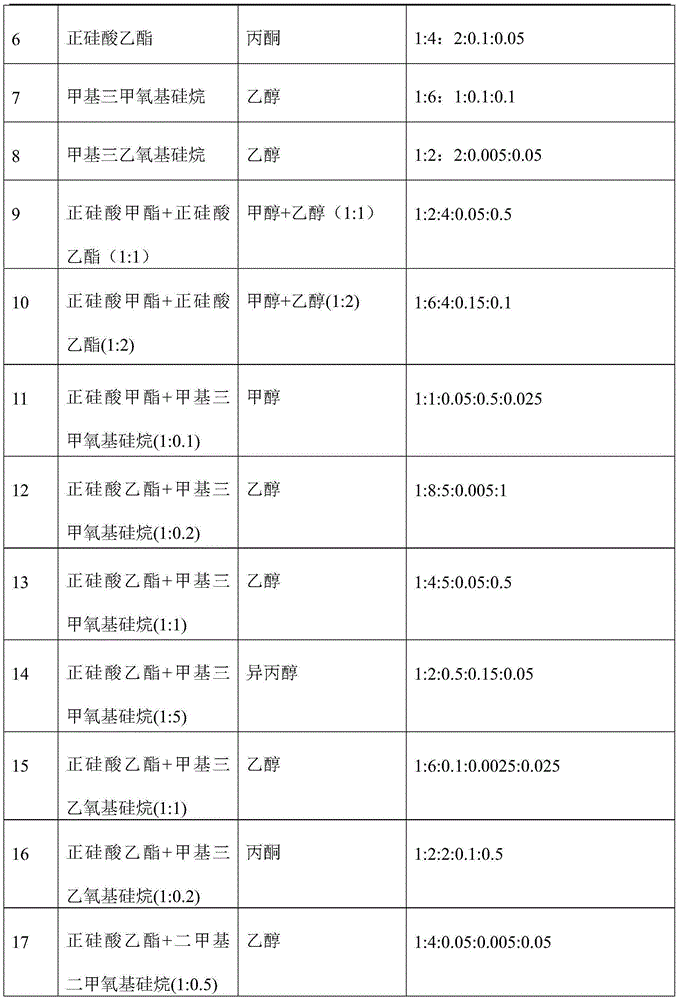

[0034] Examples 2 to 20 were carried out in the same manner as in Example 1. Among them, in Examples 4, 11, 13, 19, 20, after cutting to obtain regular-shaped silica gel particles through the previous steps, supercritical drying can be used directly to obtain regular-shaped silica aerogel particles , No aging step is used.

[0035] Table 1 shows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com