Mass preparation method and device of graphene quantum dots

A graphene quantum dot, large-scale preparation technology, applied in graphene, nano-carbon and other directions, can solve the problems of low yield and low purity of graphene quantum dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are examples of the present invention, and the reagents used in the examples are chemically pure.

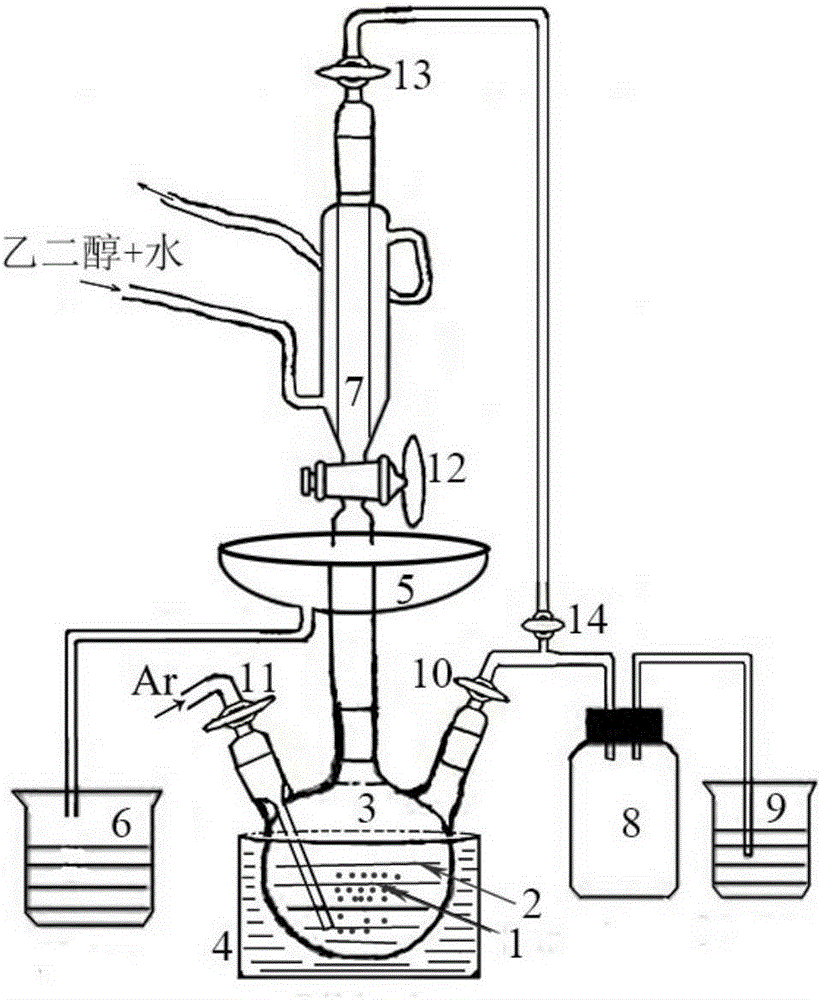

[0031] Design a condensing tube with a switch and an oval drop recovery device by yourself, use XC-72 carbon black as the raw material, and use concentrated nitric acid as the oxidant; put 1.6g of carbon black and 300ml of concentrated nitric acid in a triangular round bottom flask , and put in a magnetic stirrer at the same time; install the water droplet recovery device on the middle neck of the Erlenmeyer flask, then install the condenser tube on the water droplet recovery device, and use the iron stand and clips to fix the condenser tube and the triangular round bottom flask at the same time; Put the mixed solution of ethylene glycol and water cooled by the low-temperature constant temperature bath device into the tube; place the triangular round bottom flask in the oil bath, raise the temperature of the oil bath to 135°C, under magnetic stirring, at 135°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com