Contactor welding contact point grinding device and machining method thereof

A welding contact and processing method technology, applied in the direction of grinding workpiece brackets, metal processing equipment, grinding machines, etc., can solve the problems of tearing of parts, damage of welding parts, etc., and achieve the effects of avoiding subsidence, ensuring strength, and avoiding tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

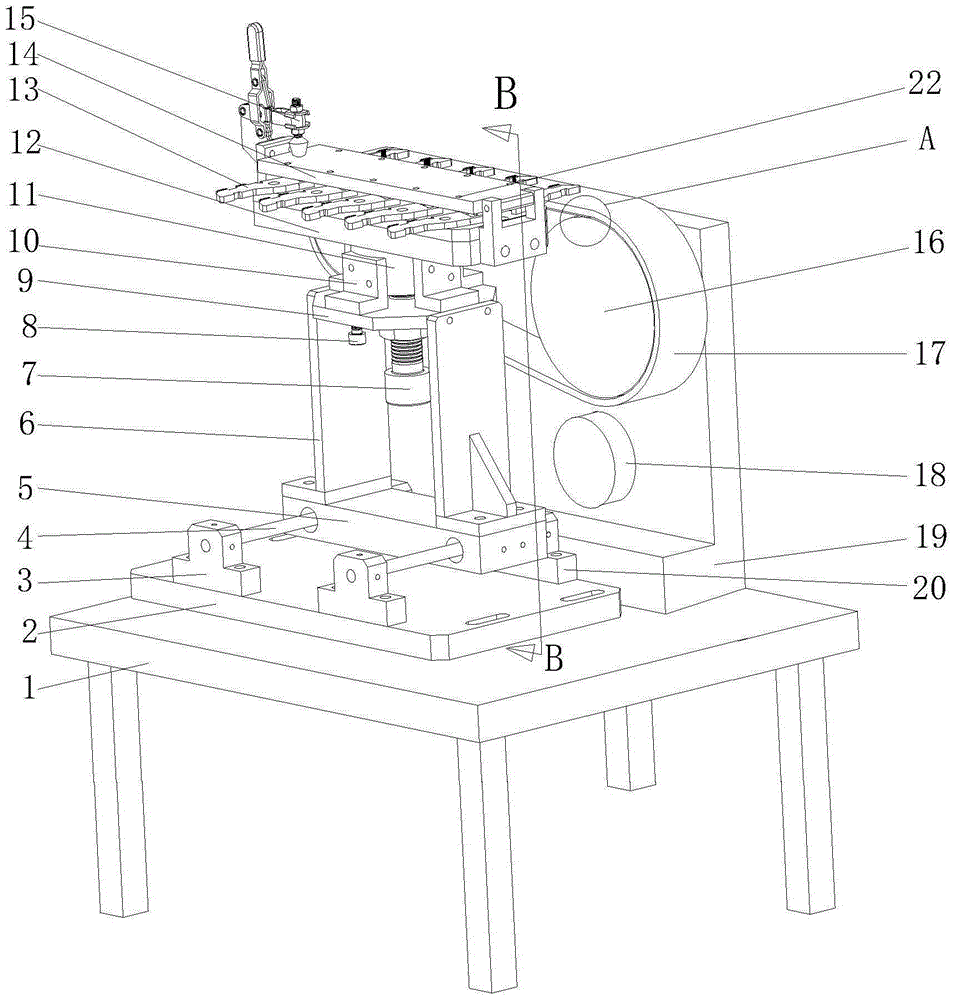

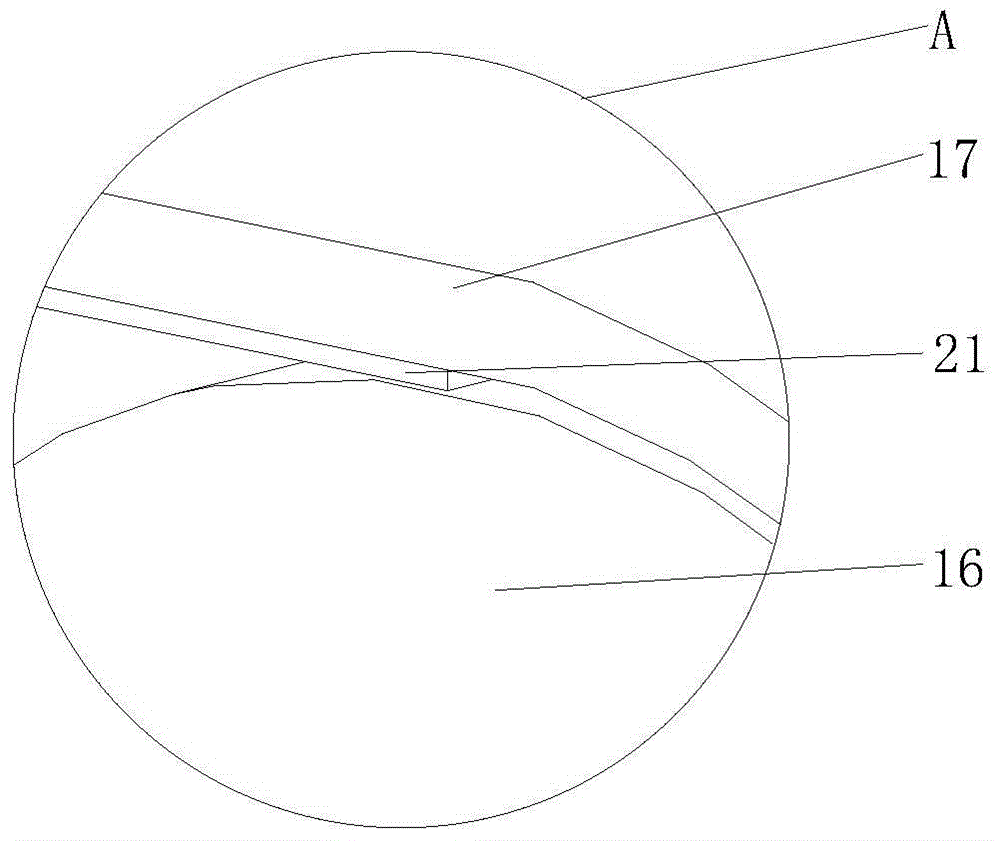

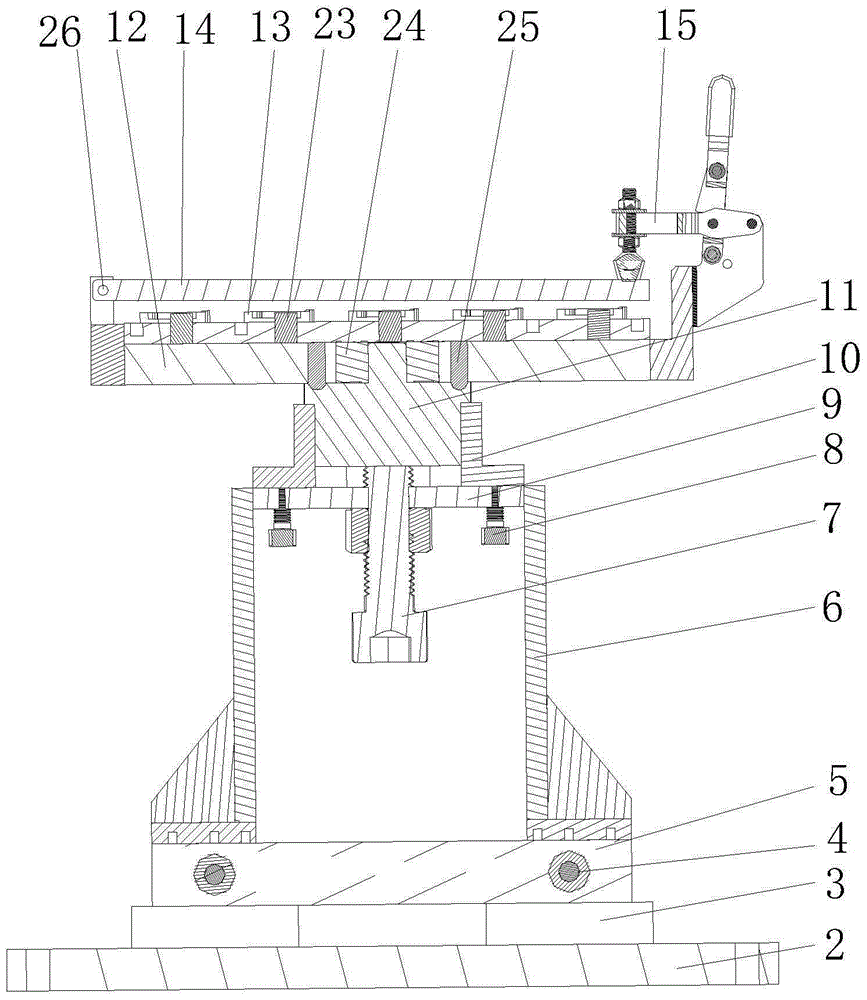

[0041] Such as Figure 1-4 As shown in one, a contact grinding device for contact welding in the present invention includes a frame 1, an abrasive belt grinding mechanism fixed on the frame 1 and a contact fixing device, and the contact fixing device includes Base plate 2 on 1, base plate 2 is provided with fixed support 6, and fixed support 6 is provided with rotating positioning plate 12, base plate 2 and fixed support 6 bottom 5 are slidingly connected, and the upper end of fixed support 6 and the lower end of rotating positioning plate 12 are rotationally connected, and the rotation positioning A double-row multi-position contact fixing structure is arranged on the plate 12. After the contacts 13 are fixed, the welding contacts of the contacts 13 extend beyond the two sides of the rotating positioning plate 12, and the fixing bracket 6 slides toward the abrasive belt grinding mechanism. The lower end of the welding contact of the contact 13 is pressed against the abrasive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com