Slot feature side milling machining tool path generating method

A groove feature and tool path technology, applied in metal processing, metal processing equipment, metal processing machine parts, etc., can solve the problems of sudden changes in cutting direction, affecting processing quality, machine tool vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

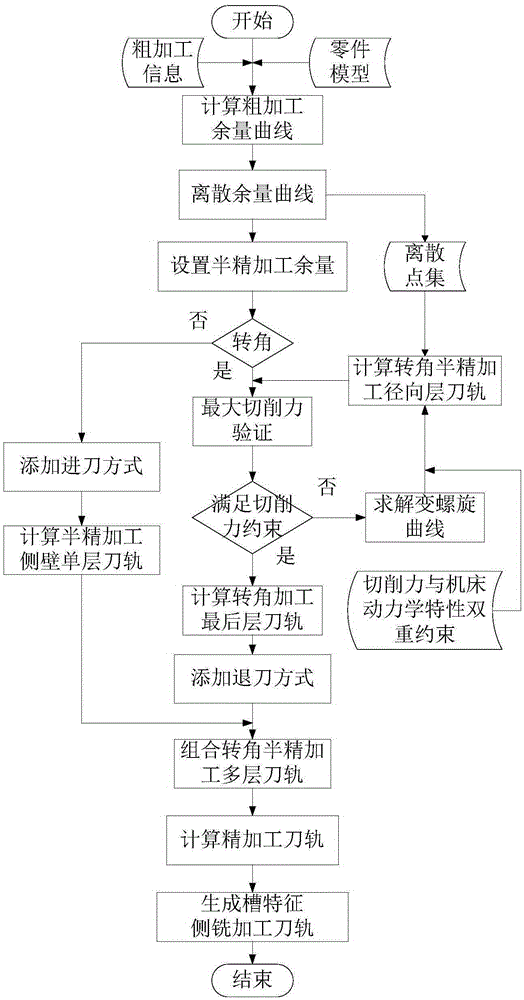

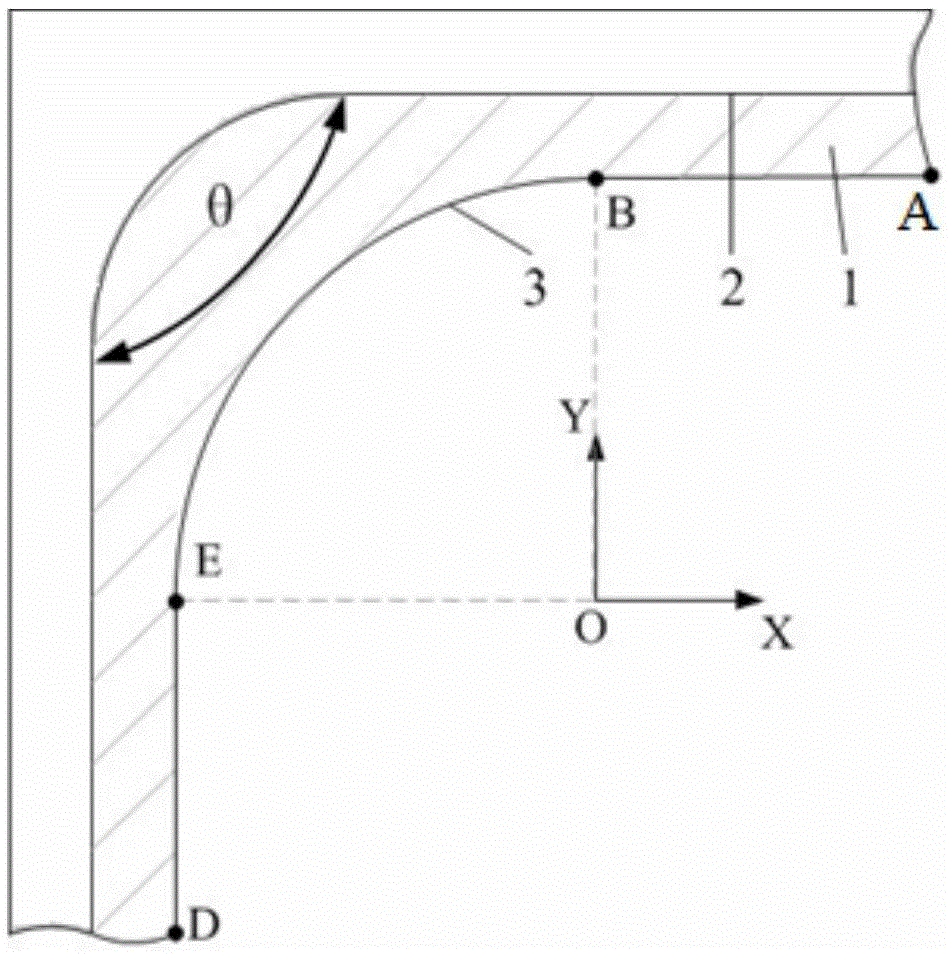

[0046] The tool path generation method proposed by the invention is based on rough machining. by figure 2 The typical groove characteristics shown in the figure illustrate the process flow of a method for generating a groove characteristic side milling tool path proposed by the present invention. The groove characteristic size is 200mm×160mm, and a Φ12mm tool is selected for processing. The groove characteristic side milling tool path generation process is as follows:

[0047] Step 1, according to the groove feature rough machining information and the part model, obtain the material allowance μ to be processed, and calculate the rough machining allowance curve;

[0048] First establish a local coordinate system, take the center of the margin arc at the corner as the coordinate origin, and take the direction of the margin line equation on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com